Aluminium Lidding Foil for Salad Cup Lidding Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Aluminium Lidding Foil:

Name: Aluminium Lidding Foil Junbo Roll for Dairy Packaging

T:0.03-0.04mm

W:50-1600mm

Application:Dairy Packagin / Lidding Packaging application

Alloy & Temper: 8011/ 8079 / -O

Thickness: 0.03-0.04mm

Width: 50-1600mm

Prodution standard: GB/T, ASTM, ENAW Standard

Packaging:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with drying agent ,without fumigation

Household Aluminium Foil Products is light weight, the products meet the national food hygiene standards.And easy to recycle,in the process didn't produce harmfu substances,and does not pollute the renewable resources.Air Products areused in the food and cake food retail market,updating the number of fast consumption.For a bulk sale.Cake cooking food store sand food packaging productsus in galuminum foi lboxes.Broader product market,popularize more.

Used Aluminum Foil packaging can be recycled and reduce pollution and save resources, is a good choice!

The Main Features of Aluminium Lidding Foil:

Suitable hardness

Without smell, impermeability

Best quality

SGS,FDA certificat

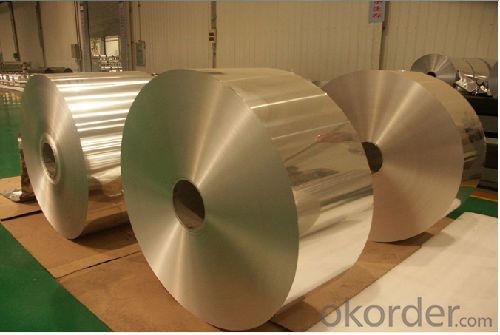

The Images of Aluminium Lidding Foil:

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q:I say once the sun stopped hitting it all the gasses would quickly condense and the temperature would fall rapidly

- I agree with your theory, but unfortunately, the technology needed for your plan is currently not availableBut creating a way of making the cloud cover rain down is one of the potential ways to cool down VenusCheck out the link belowIt has a few ideas for terraforming Venus using current technology.

- Q:The only things i can use are:Popsicle sticksAluminum FoilWax PaperStrawsAnd Tape (NOOO GLUE)lt;- my teacher wont let us.

- I usually spread a little vegetable oil or olive oil in the bottom of the roasting panThat keeps the bottom of the turkey from sticking to the pan, and it also gives you the beginning of the fat you can use to make your gravy afterwardsI don't know how much to tell you to use because I don't know the size of your panMaybe 1/4 cup? Then you can always add a few Tbsp of water as the turkey cooks, and then baste the turkey with the water/oil mixtureThat will help keep the turkey moist, tooI usually put a tinfoil tent over my turkey for the first half of the cooking time, so the skin doesn't get so darkThat helps moisten the turkey, too.

- Q:can someone tell me some paper shooters like hornets but that hurt more and can you tell me how to make them?

- We call them bruisers where i'm from, but i think we mean the same thingPaper works fine, its just how you role itMy ones make people bleed :P You want small, tight roles, after you bend it in half it should be no more than 2cm on each wingIve also thought about experimenting with aluminium foilJust remember roll it TIGHT.

- Q:How do things get freezer burnt?

- Make a checker board and piecesTake a piece off a carton like used for 12 pk drinks to make your boardUse a permanent marker or black string with tape or glue to create your boardThen take the bottom off the coke bottles or soda bottleUse them as pieces and cover them with old shirt material using hot glueRed and Black should be fairly easyFinally color your board the same colors by using old crayons or markersOr you can take an old shirt, sew the neck hole upLeave the arms openThen take a long sleeve button up shirt and sew the arms from it into the shirt as one long sling to place around you from your shoulder to your hipthis could be a baby doll sling for small childrenHope this helps.

- Q:i need a good rib recipe my mom says she never makes them cuz they always turn out bad.i perfer the bbq ones not the dry ones.any good recipes?.if not sites to the recipe(perfer the recipe)

- I just got one from superior tattoo I think it was the raven, but I'm not really sureIt is not metal and it is very light to hold, I enjoy using it and because it is so lite to hold (7 oz) I do much better lines and coloring I also got one from Joe Kaplin that I like really well also, so I guess it is just a matter of opinion.

- Q:I've read that Jade is harder than steel and cannot be cut easilyThe Jade is shaped and cut only by a material which is even HARDER, but I don't know what Material, Can someone tell me?

- Take a cap from a different pen.If it fits okay youd be surprised at how it works to keep it from drying out!

- Q:I am looking for an Simple Paper Mache (Small) Doll RecipeI Don't Want To Use NewspapersWhite Strips (?

- I love club penguinCan't liePlay tetris or just search free games.

- Q:First, Gore sets up a company that will invest in other companies that will benefit from global warming alarmismSecond, Gore gets some Hollywood types to fund and produce a movie designed to scare the c-c-carbon out of the populationThird, Gore travels the world promoting this movie, while pushing the view that a cataclysm is imminent if the world doesn't immediately actFourth, an adoring media falls for the con hook, line, and sinkerRather than debunking the flaws in the theories, the media promote every word of it while advancing the concept that Gore's views represent those of an overwhelming majority of scientistsFifth, scared governments and citizens across the globe invest in alternative energy programs driving up the shares of companies Gore's group has already invested inSixth, Gore and his cronies make billions as they laugh all the way to the bank at the stupidity of their fellow citizens

- Roman's invented roads, steel swords, perfected the tortoise manoveur, invented aqueducts to bring water from the coastHan Dynasty helped invent things like gunpowder, fireworks, The Great Wall, the wheel barrow and the wheel.

- Q:I am in AP Bio and it's the 1st day of real workWe are doing a review but since I am a sophomore I haven't taken regular bio yet, I don't know how this was doneThe people in my group were no help and I do not want to fail so if you know a website or can explain it simpler please doI need to to it for 1) Phosphorus 2) Sulfur 3) Bromine 4) NeonI will admit I searched how to do Phosphorus but the answer doesn't help mePlease Explain! :D You will make my life easier.

- you can go to Lowe's or the Home Depot and get like Pink Panther Fiberglass Insulation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Lidding Foil for Salad Cup Lidding Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords