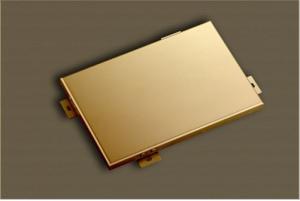

Aluminium Foil Tape for PIR Duct with UL Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 roll

- Supply Capability:

- 200000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Foil Tape Description

1. Specifications of Aluminium Foil Tape T-S3004P

PROPERTIES | UNIT | VALUE | TEST METHOD |

Alu Foil Thickness | micron | 30 | GB |

Adhesive Coating | g/m2 | 40 | GB |

Adhesive Type | ------- | water acrylic | GB |

Peel Adhesion | N/25mm | 11 | GB |

Rolling Tack(11mm ball) | cm | 20 | GB |

Fire Rating | ------- | Class 0 | BS476 |

Temp Resistance | °C | -20-+120 | ASTM E84 |

1) Roll length: 27m-1000m

2) Roll width:50mm-100mm

3) Jumbo roll: 1.2m x 1,200m, 1.2m x 1,000m

2. Applications and Features of Aluminium Foil Tape T-S3004P

1) HVAC system for building thermal insulation,suitable for sealing seams and joints of various laminated insulation facings.

The applications include: Duct Wrap, Wall Insulation, Metal Building Insulation,

Pipe Insulation, Hot Water Tank Insulation.

2) Electronic refrigeration fields ,Used for refrigerator industry, masking operations in electroplating and paint stripping, also good at protecting cable splices, metal patching and sound dampening applications.

3. Package & Delivery of Aluminum Foil Tape T-S3004P

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / ply-wooden case

Jumbo roll: ply-wooden case

4. Production Flow of Aluminum Foil Tape T-S3004P

The main producing procedure includes the following steps:

Raw material-Adhesive Coating-lamination-Wrapuping-Cutting-Packing

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Aluminum veneer and aluminum-plastic plate which is good? Will aluminum veneers corrode?

- Aluminum is pure metal, aluminum-plastic plate is the surface of the aluminum is the middle of the plastic layer.

- Q:Home decoration, aluminum-plastic board in general how thick ah?

- The thickness is not according to the wire that is about 1 mm side of the double-sided if the outdoor use of the estimated 5 mm or more

- Q:Do you have a board on the back of an aluminum - plastic panel for exterior decoration and advertising

- What materials can control a few months it. A long time, what materials will be bad.

- Q:3.6mX1.5 bathroom 3.6mx2.1 kitchen with aluminum plate ceiling. Using wooden skeleton, made of removable. Seeking solutions. Thank you! The How much is the cost? The

- These two kinds of ceiling are buckle plate, and wood flooring as a slot (male and female slot), Bunsen is removable. The cheapest aluminum-plastic plate is about 30 yuan per square meter, up to a year began to yellowing, fading, deformation and surface off, will be ugly cry. Aluminum buckle the cheapest probably about 60 yuan per square meter (with pieces of magnet, some metal posing), of course, can not control how long, the surface will be oxidized, but how better than the aluminum plate. Cost to see which one you choose.

- Q:I want to open a small aluminum-plastic plate factory, how much money

- Production of aluminum-plastic board products, the need for pretreatment, painting, composite three sets of equipment, this down 800,000 on it, if it is a small factory, then you can find third-party manufacturers to paint, you can only on the composite line, so Single equipment 50 million enough.

- Q:Aluminum-plastic plate what material can do the door

- Acrylic

- Q:28 silk 4MM aluminum plate how much money, use it to do the outer wall about how much money

- If the landlord is in the market to understand the 28 silk 4MM aluminum-plastic plate should actually refer to 20 silk 4MM aluminum-plastic plate, because as an aluminum-plastic plate manufacturers can not tell customers that their aluminum-plastic plate is the next tolerance

- Q:It is good for aluminum manufacturers of aluminum alloy cans

- Do you need aluminum or aluminum cans?

- Q:Features of aluminum-plastic panels

- good weather resistance, high strength, easy maintenance.

- Q:As long as the aluminum-plastic plate can fire it? Online and so on

- Because the fire performance is also a level of terms,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil Tape for PIR Duct with UL Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 roll

- Supply Capability:

- 200000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords