Aluminium Foil Mylar for Cable Industry from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

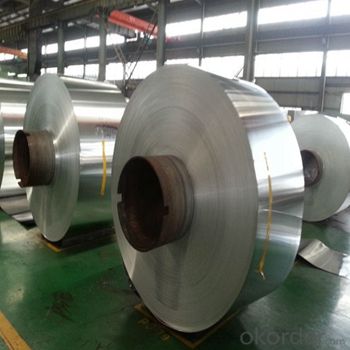

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Where is the use of high pressure etching into electronic aluminium foil?

- In order to change this situation, domestic manufacturers have done a lot of work in localization. Shortly before the SWA electrolytic capacitor for high voltage aluminum foil on the success of the project development, product quality has reached the international advanced level, can completely replace imported. It should be said that after more than 10 years of development, especially in the last five or six years, the quality of China's electronic aluminum foil has been greatly improved.

- Q:How aseptic packaging aluminum foil bags?

- Aluminum foil bag is a major cause of the two pollution products after sterilization, disinfection quality of packaging damage to chemical or physical methods of conventional microwave disinfection than conventional heating disinfection required low temperature, a great impact on the quality of the product will not. The use of microwave technology in soy sauce packaging bags to prevent halogen, can prevent soy sauce due to packaging caused by the two pollution problems, and prolong the shelf life of bagged products. In the case of plastic bag sterilization, mainly for sealed aluminum foil bags.

- Q:What is the recycling of aluminum foil packs?

- Not only recycling paper lunch boxes to be put into the container, but also to the aluminum foil bag thrown into the container, rather than paper, because not all components of the aluminum foil bag inside pulp, and plastic film 20% and 5% aluminum foil, if they are treated with waste paper, paper pulp dispersion time is not enough, no crime was isolated from Crucian Carp it can lead to the recycling of the resources, if sent to incinerators will detract from the life of the incinerator.

- Q:How do you test the resistance value of the aluminum foil of the capacitor?

- Add a capacitor higher than the rated voltage of 20%, after 5 minutes without current, you can believe that the pressure qualified.

- Q:Does the disposable aluminum foil lunch box affect your health?

- The aluminum foil lunch box is one of the most healthy food packages now. The foil box has no influence on the body. It can rest assured.

- Q:Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Handheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q:What's the flow of aluminum foil statistics?

- The width of the aluminum foil is cut according to the user's requirement, but the width of the rolling is different from that of the rolling mill, and the maximum is 2m.Aluminum foil varieties have roll foil and foil, and hard foil and soft foil. The aluminum foil which is directly rolled by the mill is called plain foil, and the treated aluminum foil is made of embossed aluminum foil, composite aluminum foil, coated aluminum foil, colored aluminum foil and printed aluminum foil (see coated aluminum foil). From the angle of purity and alloy variety: industrial pure aluminum foil (purity 99.7% ~ 98.8%), iron aluminum (including Fe1%), the high pure aluminum foil (purity 99.85% ~ 99.99%) and Aluminum Alloy foil (aluminum manganese alloy foil, aluminum magnesium alloy foil and hard aluminum foil etc.). Can also be classified and addressed from the use of, such as packaging aluminum foil, capacitors, aluminum foil and so on.The use and consumption of aluminum foil, aluminum foil is widely used, see Table 3, so the annual consumption is very large, for example, in recent years, the United States is about 400 thousand T, Germany and Japan for 100 thousand T or so, Britain, France and China is about 50 thousand T.

- Q:The working principle and characteristics of hand held aluminum foil sealing machine

- 1. Choose the flat surface, steady the machine, insert the joint of the inductive head into the socket on the front panel of the machine and screw it tightly. Pay attention to the orientation of the socket.2. One end of the plug of the power cord is inserted into the power supply socket on the rear plate of the machine case, and the other end is inserted into the power supply socket, and the single-phase three wire power supply must be used. Voltage 220V, socket can withstand more than 10A current.3. Turn on the power switch on the rear panel of the cabinet. The sealing time of the control panel is bright and the machine can work.4, press and hold the time setting button, according to the need to seal the diameter of the container, material set a suitable value, setting value between 0.1-3.9 seconds.5, the container alignment of the sensor head of the center (previously placed induction aluminum foil container cover and tighten the membrane compaction) by induction power switch on the handle, then the original set time countdown to zero, said the work has been completed, and then remove the sensor head container under a sealing operation.6, check the sealing quality, according to different materials, diameter containers, as well as production efficiency, appropriate trimming time setting button, so that the sealing quality to the best.7, do not work, press the power switch on the front panel closed.

- Q:The difference between aluminium foil alloy 1060 and 1235

- The rolling process is rough rolling, rolling, finishing, slitting, annealing and packing. The product has a variety of functions such as aluminum foil, foil, food bags, capacitors etc.. Largest customer - Tetra Pak packaging.

- Q:Does the FFC package foil have no grounding, which is equivalent to adding a capacitor to the cable?

- It should be equivalent to adding a return path to the high speed signal

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil Mylar for Cable Industry from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords