Aluminium Foil Mylar for Cable Industry from CNBM for Bubble Heat Seal Composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

2.Main Features of the Aluminum foil facing:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

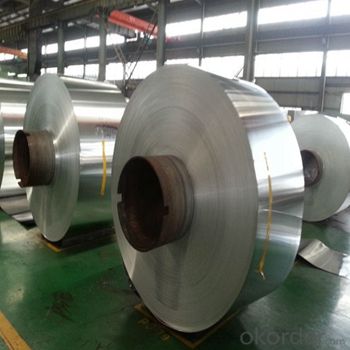

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Is there any harm to the pure milk packing aluminum foil in boiling water?

- As the soft packaging materials, it is in order for us to buy and carry, and is not used as a heating container, so consumers should Hot Milk when drinking or recommend it from this bag onto the glass, or kitchen use high-temperature beaker, containing the aluminum foil packaging milk is absolutely not to heating with microwave oven. In addition, over heating milk also has an impact on nutrition.

- Q:What can be used to make foil?

- Flexible package is a kind of bag container made of soft composite packing material. The flexible package not only has the function of moisture-proof and preservation, but also can print various patterns and characters. It is an ideal material for modern commercial packaging. With the improvement of people's living standard, there is still a lot of room for the development of flexible packaging aluminum foil.

- Q:Relationship between capacitor capacity and aluminum foil

- If it is the gold film capacitor, the medium is the film, the voltage is high, the medium is more, so the capacity is not only related to the area of the aluminum foil, but also to the thickness of the dielectric. Generally speaking, if the voltage is determined, the larger the area of the aluminum foil, the greater the capacity!

- Q:Aluminum foil lunch box microwave oven operation method?

- Microwave ovens should not use aluminum foil or other metal containers.Would you like to make sure it's a microwave or a light vessel?.

- Q:Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Hand held aluminum foil sealing machine operation method:The container with aluminum foil sealing machine alignment sensor head center (previously placed induction aluminum foil container cover and tighten the membrane compaction) click on the handle "induction switch", then the original set time countdown to zero, said the work has been completed, and then remove the head of a container under induction a sealing operation.Check the sealing quality, according to different materials, diameter containers, and production efficiency, and properly trim the "time setting button", so that the sealing quality to the best.

- Q:Can the aluminum foil bowl be heated by microwave oven?

- Well, yes, some foil boxes can be heated directly in a microwave oven

- Q:What's the flow of aluminum foil statistics?

- There are two ways to produce aluminium foil: rolling and vacuum evaporation (see deposition foil material production).

- Q:The working principle and characteristics of hand held aluminum foil sealing machine

- The machine can be divided into two parts: the control box and the output induction head. 100KHZ high frequency current generated by the microcomputer control source by amplifying, shaping, push the power module output to the sensor head, when the metal aluminum foil container Gary proximity sensing head, eddy current heating on the aluminum foil, heating degree by the intensity and duration of the short length to determine eddy current. The whole machine is equipped with an automatic frequency stabilizing circuit, the function time can be adjusted and the working status can be displayed. This machine has been improved to slow the sealing speed of the 500A model, so that the machine can be continuously heated by heating without stopping once. Therefore, the sealing speed of the machine is much faster than that of the 500A model.

- Q:Does the FFC package foil have no grounding, which is equivalent to adding a capacitor to the cable?

- It should be equivalent to adding a return path to the high speed signal

- Q:Are aluminum foil lunch boxes much used in the country?

- In Europe, America, the Middle East, including the present middle east. Plastic tableware is gradually being replaced by aluminum foil products. However, in the context of growing concern about environmental protection, this lunch box has developed rapidly in recent years, and many enterprises have begun to seize the market, and the future prospect is vast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil Mylar for Cable Industry from CNBM for Bubble Heat Seal Composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords