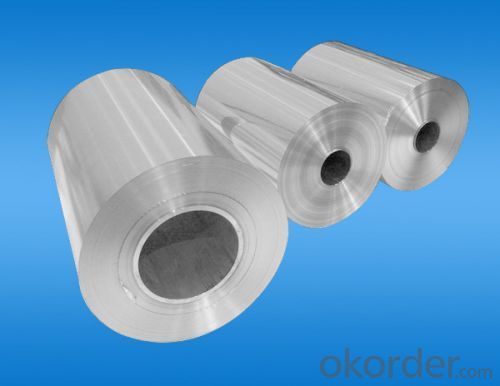

Aluminium Foil High Quality with Flexible Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Delivery Detail: | 30DAYS |

|---|

Aluminium Foil with Flexible Packing

Aluminum foil within the thickness range between 0.006mm and 0.009mm is usually referred to as “Double Zero Foil”. This foil can be laminated with paper or other material to make the packaging of tobacco and food.

Type | Double Zero Foil for Lamination |

Application | Cigarette Packaging, Lamination and Food Packaging |

Alloy Type | 1235, 8011 |

Tempe | O |

Thickness & Tolerance | 0.006~0.009 MM (Tolerance =±6%) |

Width & Tolerance | 280MM -1500MM (Tolerance: 1MM) |

Typical Core I.D. | 76 MM , 152 MM |

Inner Core Materials | Steel,Aluminum core |

Mechanical Properties | Tensile Strength(U.T.S): 35 MPA - 100 MPA |

Elongation≥0.5% | |

Adopted Standard | GB3198(China National Standard) |

Package: | Seaworthy Export Standard Wooden Box |

Special specifications are available on customer’s requirement. | |

Photos

- Q:I want to make Vaseline soaked cottons balls for a survival kiti want them wrapped in aluminum/ tin foilHow can i do that so that they will burn for 30+ min?

- Cut your squares of foil, then melt your vasaline using a double boiler (A saucepan with 1 of water and a bowl sitting on it will suffice) dip the cotton balls until saturated, and set each on a square of foil, and wrap it upStore them in a ziplock bag along with a couple disposable Bic lightersMatches are not nearly as reliable as lighters as long as the lighters remain dryOf course wet matches aren't reliable eitherThe difference is, a lighter will dry out and work if you shake it to get the water out and blow on the striker wheel and keep trying it until it lightsThis won't work with wet matchesWaterproof matches are not as reliable as they are touted to beI've had whole, new, dry packages of them that wouldnt light worth a damnI'd aviod flint and steel and Magnesium firestarters as these are overpriced gimics in a day when you could simply flick your Bic insteadLeave the flint things to the caveman wanna-be's and use a lighter like Modern ManYour home made firestarters should work quite wellI don't know that they'll burn a full 30 minutes, but they'll certainly burn long enough to get a good fire going.

- Q:1ringing of the/on migration/most/has come/from/information/young and adult birds2.stamped with/a light aluminium ring/a number and return address/is fastened/before it/leaves the nest/to the bird3.a special register/released/a detailed record/and/is kept in/is/the bird/then4.extensively employed/the method/of/has been/ringing birds/factual data/in recent years/in europe and america/for collecting

- 1 Most of the information on migration has come from ringing of the young and adult birds2 A light aluminium ring stamped with a number and return address is fastened to the bird before it leaves the nest3 A detailed record is kept in a special register then the bird is released4 The method of ringing birds for collecting factual data has been extensively employed in recent years in Europe and America.

- Q:I bought some Fimo Soft clay today, and I am going to bake it in my toaster ovenMy toaster oven doesn't have a temperature knob.so I don't know how to bake it.- What is the baking temperature of a toaster oven, usually?- Would it help if I wrap the Fimo clay in Aluminium foil.because I will be using the toaster oven for baking food as well.- Does Fimo clay air dry?

- the hollow is clever and it does not could be crammedA vapor barrier could be required if a three/4 timber floor is to be put in on precise of timber furring stripsLetting the flooring acclimate in simple terms before installation could be extreme in a basement installationThe timber could have an inclination to enhance because it responds to the greater humid air interior the basementfor a similar reason the flooring could have room for develop at any / all wall and / or column restraintscommunicate the dimensions of the open develop joints on the partitions with the corporation of your floor textilethey'll could understand the dimensions of the room to furnish the suggestionsadditionally verify the joint beginning length to be allowed between each and every of the flooring boards with the corporationevaluate applying a dehumidifier to maintain moisture administration.

- Q:I was given a plastic spoon with a dry mix for dip attachedAll I had to do was open the mix and add sour cream and mayoI would like to duplicate this or make other recipes but can't find anyAnyone have any ideas?

- I would try pinch of salt and sugar mixed in a glass of waterUsually works for me! Take that every few hoursHave you tried Imodium?

- Q:My cookies are always hard! I don't over cook them, they are soft when i take them out of the oven but then later they are hard and crunchyBut it's only with snickerdoodles and cookies that are rolled in sugar, is the sugar whats making them hard???? Coz when i dont roll them in sugar they are ok!

- The right side is the side you have showing when wearing the sweaterPurl wise means put the point of the right hand needle thru the stitch on the left hand needle as though you were going to do a purl stitchThen slip the stitch off the needle without knitting itTurn the work means turn the knitting and put the right hand needle in your left hand and the left hand needle in your right hand.

- Q:I got obsessed seeing these in the marie antoinette film, and Id like to make a gang for my birthday -but how?thaaanks!!

- fairly you have the suitable spelling right hereFrench macarons are cookies that are packed with cream and so forthMacaroons are coconut cookiesSo, check out: Chef Rubber Albert Ouster Imports worldwide Sugar artwork those furnish you with what you decide directly to realize.

- Q:Can anyone recommend any relatively simple ways to cook a turkey so it has more moisture? Last year, I tried a new technique which was cooking the turkey breast side down, because I heard the juices drip down to make the breast meat moister, but in fact, it turned out dry and kind of stringy:-(Does anyone have any fool-proof turkey cooking methods? Thanks!

- I usually go by the 3-day rule for leftovers in the fridgeIf you froze it, it could last longer.

- Q:I want items that are a bargain.

- Buy a better quality to begin with.

- Q:I need to buy the mini ones for my businessBut not knowing their actual name is limiting my internet search to order them

- Aluminum pie pans, little ones are called tart pans.

- Q:I am planning to make a gadget for making a soft-boiled egg using the heat from the sun using a mirror or aluminum foil to reflect heat in order to boil the egg... gets? :)

- you're not really after their ability to conduct but rather their ability to reflect light. As they are both shiny metallic surfaces they will both reflect a lot of light/heat, if there is some difference in their quality it probably wont be significant in light of what you want to use it for. Just use mirrors, they are more precise when it comes to directing the light which you'll want to do. Jim.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil High Quality with Flexible Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords