Aluminium Foil for Kitchen Food Wrapping 8011-O

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Description of Aluminium Foil for Kitchen Food Wrapping 8011-O

Denomination:Aluminium Foil For Food

Final Application:Aluminium Foil For Food

Alloy&Temper: 8011-O

Thickness: 0.03--0.007mm

Width:200mm--700mm

we are specialized in producting aluminum foil.

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Aluminium Foil for Kitchen Food Wrapping 8011-O

Alloy: 8011

Temper: O

Thickness: 0.08-0.2mm

Core ID: 76mm, 150mm, 152mm

Width: Variety

Application: Food Wrapping

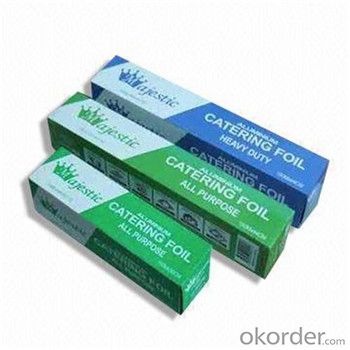

4.Pictures of Aluminium Foil for Kitchen Food Wrapping 8011-O:

5.FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T, etc.

If you are interested in our products, please do not hesitate to contact with us via following information

- Q:I know the diatomic molecules and what it means, but I don't understand what happens with them in a equation:s If they are on their own do you put the 2 in and then leave it out when it is with another element and use the valencys?, like this:Aluminium + Flourine -gt;Aluminium Floride Al + F2-gt; AlF3 (not balanced) 2Al+3F2-gt;2AlF3 (balanced)Is that right or wrong? Thanks:)

- properly in case you choose to be hit mutually as wearing it that's advisable to start with a card board base for the variety, use countless loose layers of coton or flannel on the interior and then aplly the carbon fiber to the exterior in some layers allowing each and every to set in the previous using the subsequent.perhaps u might desire to upload a layer of kevlarstable success

- Q:How do I get my cat to stop chewing fish tank air tubes?

- It could just be your normal body temperature and nothing moreMy step-mom has a normal body temp of about 94, so when she registers a body temp of 98.6, it is a feverDon't forget, 98.6 is called an average temperature not THE temperatureI doubt that it's anything to worry about, but if you really are concerned, you could always ask your doctor if this is just your temp or if something is causing this to be your temp.

- Q:My husband got hurt on a machine at his job and it cut his hand up pretty badThe doctor cleaned it but not good enough and there is still a small peice of aluminum in his handI need to know if it's fine where it is or if it is dangerous to his health and needs to come outThe aluminum was treated with chemicals before it cut him.

- fiberglass is the way to go 4 thick will do the jobMake sure you wear safety glasses and a reperator, long sleves and long pants when you do the work,

- Q:We have an indoor grill for 4 years now and the non stick coating is worn off in the middle where it gets the most cookingIt still works greatIs there any chance of the aluminum contaminating the food?Thanks

- Vegetables, fruit, brown rice, wheat berries, whole grain bread, whole grain pasta, legumes (peas, beans, lentils), whole grain cereals, nuts, seeds.

- Q:i own a ford explore xlt and it has nbxwhat does the nbx main?

- NBX adds to XLT: 17-inch machined aluminum wheels, P245/65R17 all-terrain OWL tires, off-road package, two-tone black front/rear bumper, black cladding, wheel lip moldings, step bars, rubber floor mats, cargo soft liner, storage bag, front tow hooks and unique cloth interior No idea exactly what the letters NBX stand for, it's just another special option group - like XLT, LS and so fourth.

- Q:Any other scientific, odd facts and fantasy to share?

- Perpetual motion is the theory which states that an object once set into motion will remain in motion until another force acts upon that objectUnless an object is in an infinite vacuum, however, perpetual motion is impossibleEven in space, the gravitational pull of the sun is sufficient to prevent most satelites from leaving this solar systemThe idea that perpetual motion is an overall myth is the generalization that such an concept could exist on earth, despite the atmospheric friction and gravity of the earth itself Atomic energy is massive when released, as Hiroshima and Nagasaki have witnessed, but for the most part, it is a close range relationship of extremely powerful attraction found in atoms, (hence, atomic energy)Many people agree that the use of atomic energy in space craft is unrealistic, at the current time, because a nuclear reactor is too heavy and bulky to lift into orbitHowever, Ben Bova's The Precipice, shows how atomic energy may be used in space travelHave you heard about the use of nano aluminum in rocket fuel? Suppousedly, after reducing the size of aluminum alloy to a certain point, it becomes explosive.

- Q:can most bike shops thread a fork for you, and what is the usual cost

- Think about substituting instead of finding a new recipe, if there's one you really like Egg substitute 1 egg 2 tablespoons liquid + 2 tablespoons flour + ? tablespoon shortening + ? teaspoon baking powder OR gelatin (To replace each egg: Dissolve 1 tablespoon unflavored gelatin in 1 tablespoon cold water, then add 2 tablespoons boiling waterBeat vigorously until frothy.) OR cornstarch (Substitute 1 tablespoon cornstarch plus 3 tablespoons water for each egg called for in recipe OR mayonnaise (Substitute 3 tablespoons mayonnaise for each egg called for in recipe.) OR bananas (Substitute 1/2 of a mashed ripe banana plus 1/4 teaspoon baking powder for each egg.) OR silken tofu (Substitute 1/4 cup tofu for each egg.) OR 1 heaping TB of cornstarch + 1 1/2 TB of water OR 1 heaping TB soy flour + 1 1/2 TB water

- Q:A1st energy level B2nd energy level C3rd energy level D4th energy level

- Hello, That will help, I always put an R-30 between my floors when I build so you can't hear much at all The biggest trick to noise reduction is overlaps of products and differing layers as that these things by overlapping and varying in thickness will act to deaden with each layer For example in a indoor movie theatre they will fill 12 block walls with sand and then each auditorium wall gets 2 to 3 layers of sheet rockIf they are smart, the layers will be 1/2 then 5/8 then 1/2 again with a dead air space or insulation between each one Well that's how we do itIn an attic , blow hard - because cellulose will settle and you don't want air space to be able to capture moisture , so pack it tight Best Regards, Joe Woodall, Managing Partner Georgia Adobe Rammed Earth And Renewable Energy Dewy Rose Georgia 30634

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil for Kitchen Food Wrapping 8011-O

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords