Aluminium foil and Panel for Packing Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Type | Double Zero Foil for Lamination |

Application | Cigarette Packaging, Lamination and Food Packaging |

Alloy Type | 1235, 8011 |

Tempe | O |

Thickness & Tolerance | 0.006~0.009 MM (Tolerance =±6%) |

Width & Tolerance | 280MM -1500MM (Tolerance: 1MM) |

Typical Core I.D. | |

Inner Core Materials | Steel,Aluminum core |

Mechanical Properties | Tensile Strength(U.T.S): 35 MPA - 100 MPA |

Elongation≥0.5% | |

Adopted Standard | GB3198(China National Standard) |

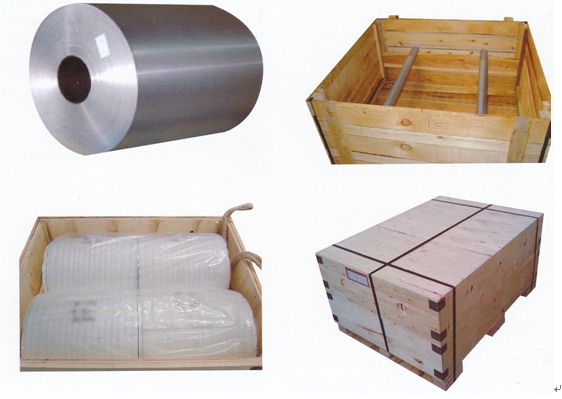

Package: | Seaworthy Export Standard Wooden Box |

Special specifications are available on customer’s requirement. | |

Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 30 days

Aluminium | Thickness (MM) | Alloy Type | Temper | Width (MM) | Core I.D. (MM) |

Double zero foil for lamination | 0.006-0.009 | 1235 | O | 280-1500 | 76 152 |

Household Alumium foil | 0.010-0.020 | 8011 | O | 300-450 | 76 152 |

Pharmaceutical aluminium foil | 0.020-0.030 | 1235 8011 | O H18 |

200-1300 | 76 152 |

Container aluminum foil | 0.03-0.12 | 3003 8011 | H22 H24, H18,O | 300-1000 | 76 152 |

Insulation aluminum foil | 0.01-0.08 | 8011 1050 | O | 900-1100 | 76 152 |

Fin stock aluminum foil | 0.1-0.105 | 8011,1100 1200 | H22 H24 H26 |

OUR SERVICE:

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

- Q:You can only use cardboard, metal, tape, glue, and rubber bands.Entire vehicle can't weigh under 300 grams, nor be more than 350 grams.Materials that can't be used:-CO2 cartidges -music box motors-any plastic or wood items-erector set piecesGoal: Getting the self-propelled car to travel the furthest distance (flat travelling surface) before coming to a stopThe track being used is 4 meters in width.

- My first thought is to make it long and thin, for maximum length of rubberThe frame has to be aluminium tube, to be stiff enough to take the loadThe real worry is going to be the wheelsIf you can't use plastic or wood, they are going to have to be multiple layers of cardboard or cardboard stiffened by metal ringsIf corrugated cardboard is permitted for the wheels, then you could even consider putting a rubber band tyre round the wheel, which would work wonders for the tractionGood luck.

- Q:I am making lemon lime fish for and have no idea what to make with itThis is the recipe:Ingredients: 1 lemon 1 lime 1 teaspoon cumin 1 teaspoon garlic, minced 1 tablespoon olive oil 3 tablespoons butter 2 salmon steaks salt and pepperPreparation:Place salmon steaks on heavy duty aluminum foilGrate lemon and lime into zest in a small bowl and set asideSqueeze both lemon and lime over salmon steaksSqueeze any remaining juice into the reserved bowl of lemon-lime zestSprinkle salmon steaks with olive oil, salt, pepper, garlic, and cuminSlice the remaining lemon and lime and lay over salmonMix butter and lemon-lime zest, take a spoonful and dab over each salmon steakFold the foil around the salmon steaksPlace foil salmon pouches on grill or open fire and cook until salmon flakes.

- That actually sounds really good and not too rich, which gives you more room to play with on side dishesSince the salmon contains citrus and cumin, pick up that profile by serving a huge green salad w/ sliced avocado, sliced oranges or tangerines, thinly-sliced red onion, and a citrus vinaigrette made w/ a bit of minced garlicA nice starch would be small boiled potatoes that you've steamed in the kitchen and finished on the grill, then tossed w/ chopped cilantro, melted butter, salt and pepperOr.you could go old-school and serve it with buttered peas and boiled new potatoes w/ melted butter, dillweed, salt and pepper.

- Q:I purchased some used rims over the weekend, the are in OKAY shape, its gonna take a lil elbow grease to get them looking niceThe thing is, i dont know if what i have are Chrome or Aluminum w/ chrome plating, some of the chrome is chipping which leads me to believe that they are aluminum w/ chrome plating? I'm not sure.any help would be appreciated.Also i would like to know what would be the best way to clean them.thanks again.

- I know exactly what to do, and I'm not kiddingI have rec'd a ton of behavior/parent training in home because of my son's autism and I have a typical daughter and all this stuff works soooo well on her When she says I 'need' you need to make her ask you nicely'Mommy, can I please have_? Everytime she says things in an undesireable way, model exactly how you would like her to say it nicelyChildren are naturally bossy, we just have to show them how to be I spent the whole week with my sister in law and her 'typical' 4 yr old daugherMy son is 4.5 with high functioning autism and we have our almost 3 yr old daughterI was shocked at how bossy this little girl was to her mother, but when she was bossy, mom just did what she wanted to shut her up, and that just reinforced that behaviorEven when my kids say I want' I say can you ask me nicely(I model it if necessary), and they totally rephrase it on their ownIt's become a habitIt is much less annoying Most kids need to be taught how to share and take turns, and talk nicely to othersThey only know how to express their needs, so we have to show them how to do it in the right way so they get their needs met, and we don't go crazy being bossed around by a child.

- Q:I'm out of wax paper and was wondering if I could substitute with parchment paperTo make a note I do not have a bamboo steamer only the regular steel oneAlthough I plan on buying the bamboo kind.

- I'd definately say the babyliss i've used them and theyre great!

- Q:I know that toilet bowl cleaner has Ammonium ChlorideOn Youtube the reaction produces a lot of heatIs there more detailed info ? thanks!

- i personal wouldnt use eighter but i do like J B WELD best if you ask this qu w/ was the last thing you but threads into ? fill that hole w/ anything its gonna be a disaster !!!! trust me cant you clean up the hole a bit and you have the screw that messed it up , if not doesnt matter get a drill guide and a set of taps they make kits for this as well as ask someone at the parts shop that will help you drill out the stripped out threads and BE -careful of how deep you drill CK THE DEPTH OF YOUR HOLE if you drill and re tapp all is good and it leaks something THATS costly GOOD LUC but try too save the threads and hole first b-4 filling w/ jb weld - cant you mount the coil pac off some other bracket?

- Q:circuit?

- The shaker flashlight is a good experiment by itselfThe magnet moves through a coilThe voltage produced is rectified and stored by a capacitor to power an LEDA really cool experiment is to take a cylindrical magnet - like the one from a shaker flashlight - and drop it down a copper tubeThis creates an EMF in the tube which opposes the movement of the magnetThe result is the magnet drops very, very slowly down the tubeCompare copper, plastic, and aluminum tubesTry a with a vertical slot cut through it to interrupt the induced current.

- Q:A.Three feet of concrete B.Three inches of lead C.Sheet of aluminum foil D.Sheet of paper 2.What thickness of material will most likely stop gamma radiation? A.Three feet of concreteB.Three inches of lead C.Sheet of aluminum foil D.Sheet of paper 3.What does gamma radiation consist of? A.photons B.electrons C.helium nuclei D.hydrogen nuclei 4.The most penetrating form of radiation is A.Alpha radiation B.Beta radiation C.Gamma radiation D.All of the above 5.Which radiation has a positive charge?A.alpha B.beta C.gamma

- tight after the insulation is put in

- Q:I had an aluminum slug that I measured the mass of as 8.669gThe length was 2.8cmThe radius was .950 cmThe volume (using a volumetric cylinder) was 3.5cm^3^We are supposed to do a calculated volume using (pir^2^h) also.but when I do it with the formula, it doesn't come out the same both waysI think I'm following everything, but it's just not coming close to being equalAm I doing something wrong, or did we (more than likely) not measure something right?

- SureAppliances like AC units, like refrigerators, work off a thermostat which turns them on and off as neededThey are designed to be left running on their own foreverIt does not make sense that a manufacturer would design and sell a unit which would fail in short order if left ON overnight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium foil and Panel for Packing Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords