Aluminium Flexible Duct (Insulated and Non-insulated)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Features and Characters of aluminium flexible ducting:

1)Non-insulated and insulated Flexible Duct offered 2) Up to 150℃ and 250℃ Max. temperature 3) Fire retardant 4) OEM&ODM service offered

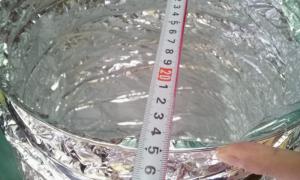

Introduction of aluminium flexible ducting:

Flexible Duct is widely used in Heating, Ventilation and Air Conditioning (HVAC) systems for air ventilation applications. Flexible Duct provides greater thermal efficiency to save energy. The product is also covered in a heavy duty, silver jacket for durability. The vapor barrier prevents condensation forming on the outside of ducts carrying air. Because it is flexible, it is easy to run around and through obstacles in the building.

1) Non-insulated Flexible Duct Structure: Two-layer aluminum foils +1 layer of PET film.

2) Insulated Flexible Duct: Structure: 1 layer of Alu. Foil+1 layer PET film+ glass wool, Outer jacket: 1 layer of Aluminium foil Glass Wool Density: 16kg/m3; Thickness: 25mm

3) Combined flexible Duct

Pictures of aluminium flexible ducting:

FAQ of aluminium flexible ducting:

1. What temperature maximum? Our products: 150℃ and 250℃

2. What MOQ? Our MOQ: 500 pcs

3. What payment terms? We accept T/T and L/C

4. What lead time: 10 days

- Q:I added the space 18 degrees opened for 5 hours or not cold, we all know how is it? More

- The general level of more than 12 layers when you need to use.

- Q:HVAC Heating: What are the main components of the air distribution system?

- Geothermal construction, the heating pipe spacing can not be less than 100mm, the construction can not be achieved, big brother!

- Q:Such as the problem, and now air-conditioning technology is mature, the market a lot of air conditioning are cold and warm, and I would like to be able to put my home that the end of the century loaded Mitsubishi air conditioning (split single cold) into a cold Before the conversion of ordinary TV to the remote control, that air conditioning can be modified? How much does it cost? Where is this technology? More

- External wall insulation should pay attention to what the details?

- Q:In the design, the building structure and the hydropower are generally designed by the Architectural Design Institute. The air conditioning ventilation is based on the design of the room. Or first air conditioning ventilation? More

- Aluminum alloy metal shell better than the plastic shell; we all know that most of the market is now charging the lithium battery, lithium battery is the only drawback is the possibility of a long time with the explosion, so the use of aluminum Alloy shell, much better than steel; polymer battery is good, but the price is expensive,

- Q:Do 3cm thick wall insulation how much kilogram of slurry and how many kilograms of polystyrene particles

- You are talking about the construction measures it is not the house measures it, because the house has a construction of Huohuohuohuo number of leather and bronze sculpture drawings and specifications, high-rise building scaffolding should be lightning protection measures, that is, under the scaffolding around Reliable grounding (not less than four times, not less than 16 square copper core BV line), if it is pick plus, and the house can be connected to the pressure ring. Tower crane I will not say, upstairs has been said.

- Q:US direct mail dysonhp01 Dyson air purification cooling machine triple in the country to warranty it

- Among them, the extruded polystyrene gypsum composite board is based on paper gypsum substrate, the use of adhesive and extruded polystyrene board through the factory processing compound

- Q:Air conditioning machine work when the sound is too much reason

- This is based on the density of benzene board decision, not what you said, know it buddy.

- Q:External wall insulation method of operation There are several combinations of materials

- Seeking the existing building construction specifications Daquan! The The @

- Q:If I feel the room cool off, one hour hot and open an hour this will be more expensive? More

- But after all, is the master you want to Zhuo good jade is certainly a lot of difficulties, whether it is Longfeng Pei or other subject matter need a lot of effort in addition to the need for technical research also need to continue to learn theoretical knowledge, especially

- Q:What is the whole heat exchange fresh air ventilator?

- Second, the new insulation decorative board is integrated through the production line, set insulation, waterproof, finishes and other functions in one, is to meet the current housing construction energy needs, improve the industrial and civil building exterior wall insulation level of the preferred material, but also on the existing Building energy-saving transformation of the preferred materials

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Flexible Duct (Insulated and Non-insulated)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords