Aluminium Extrusion Profiles For Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

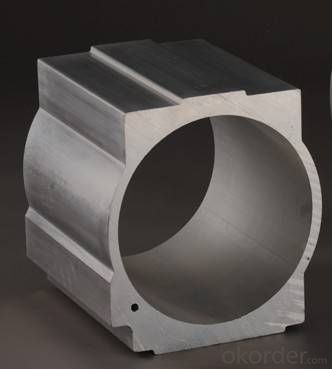

1. Structure of Aluminium Extrusion Profiles For Motor Cylinder Shell Description

Aluminium Extrusion Profiles For Motor Cylinder Shell is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Extrusion Profiles For Motor Cylinder Shell

Aluminium Extrusion Profiles For Motor Cylinder Shell | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Extrusion Profiles For Motor Cylinder Shell

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Extrusion Profiles For Motor Cylinder Shell

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Extrusion Profiles For Motor Cylinder Shell

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Aluminium Extrusion Profiles For Motor Cylinder Shell

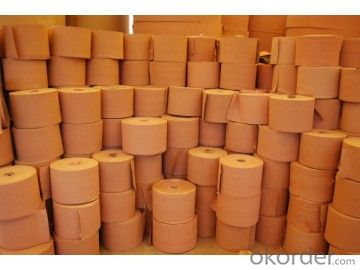

7. Package and shipping of Aluminium Extrusion Profiles For Motor Cylinder Shell

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum offers excellent electrical conductivity, and its lightweight nature makes it a cost-effective choice for busbar applications. Additionally, aluminum profiles can be easily shaped and customized to meet specific requirements, making them suitable for various electrical systems.

- Q:Are aluminum profiles suitable for cleanroom applications?

- Yes, aluminum profiles are suitable for cleanroom applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for use in cleanroom environments where cleanliness and hygiene are paramount. Aluminum profiles can be easily cleaned and sterilized, and their smooth surface prevents the accumulation of dirt, dust, or particles that can contaminate the cleanroom atmosphere. Additionally, aluminum profiles can be customized and easily integrated with other cleanroom components, such as panels and doors, to create a seamless and hygienic environment. Overall, aluminum profiles offer the required strength, cleanliness, and versatility needed for cleanroom applications.

- Q:What are the different machining options for aluminum profiles?

- There are several different machining options available for aluminum profiles, depending on the specific requirements and desired outcome. Some of the most common machining options for aluminum profiles include: 1. Milling: This involves using rotating cutting tools to remove material from the aluminum profile, creating complex shapes and features. It is a versatile option that can be used for both roughing and finishing operations. 2. Drilling: Drilling is used to create holes in the aluminum profiles. It can be done using either a conventional drill or a CNC machine, depending on the precision and accuracy required. 3. Tapping: Tapping is the process of creating internal threads in the aluminum profiles. It is commonly used for fastening purposes, allowing screws or bolts to be securely attached. 4. Turning: Turning is a machining process that involves rotating the aluminum profile while a cutting tool is applied to create cylindrical shapes or features. It is often used to create precise round components such as shafts or pins. 5. Sawing: Sawing is a cutting process that utilizes a saw blade to cut through the aluminum profile. It is commonly used for cutting profiles to specific lengths or creating straight cuts. 6. Bending: Bending involves applying force to the aluminum profile to reshape it into the desired form. This can be done using various methods, such as press brakes or roll forming machines. 7. Grinding: Grinding is a finishing process that uses abrasive particles to remove small amounts of material from the surface of the aluminum profile. It is often used to achieve a smooth, polished finish or to remove any imperfections. 8. Welding: Welding is a joining process that is commonly used to connect aluminum profiles together. It involves applying heat and pressure to melt and fuse the aluminum profiles, creating a strong and durable bond. These are just a few examples of the different machining options available for aluminum profiles. The choice of machining method will depend on factors such as the desired shape, size, and finish of the profile, as well as the specific application requirements.

- Q:How about the price of aluminum profile?

- Aluminum prices are calculated according to the price of aluminum ingot + processing fees, such as: aluminum ingot price 16000+, processing fee 6000 = 22000 yuan / ton

- Q:Can aluminum profiles be used for creating protective enclosures?

- Yes, aluminum profiles can be used for creating protective enclosures. Aluminum is a durable and lightweight material that can provide excellent structural integrity and protection. It is resistant to corrosion, making it suitable for various indoor and outdoor applications. Additionally, aluminum profiles can be easily customized and assembled to meet specific enclosure requirements.

- Q:How do aluminum profiles compare to other materials like steel or wood?

- When comparing aluminum profiles to materials such as steel or wood, there are several advantages to consider. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This characteristic also results in reduced installation time and cost. On the other hand, steel is considerably heavier, posing a greater challenge when working with it. Secondly, aluminum profiles possess excellent corrosion resistance. Unlike steel, which can rust over time, aluminum naturally forms a protective oxide layer that prevents corrosion. This feature makes aluminum profiles more suitable for outdoor applications or environments with high humidity or exposure to harsh chemicals. Additionally, aluminum is highly malleable, allowing for effortless customization and fabrication. It can be easily extruded into various shapes and sizes, making it versatile for different architectural and industrial applications. Conversely, wood is limited in terms of its shape and size due to its natural properties. Furthermore, aluminum offers good thermal conductivity, meaning it can efficiently transfer heat. This makes it an ideal choice for applications that require heat dissipation, such as heat sinks or radiators. In contrast, steel has lower thermal conductivity. In terms of aesthetics, aluminum profiles provide a sleek and modern look, which is often desired in contemporary designs. Wood, although providing a natural and warm appearance, requires regular maintenance and can deteriorate over time. Lastly, aluminum is a sustainable material. It is 100% recyclable and can be reused without losing its original properties. While steel is also recyclable, wood is not as easily recycled and can contribute to deforestation. Overall, aluminum profiles offer numerous advantages over materials like steel or wood, including lightweight construction, corrosion resistance, malleability, thermal conductivity, aesthetic appeal, and sustainability. These factors make aluminum a popular choice in various industries, including construction, automotive, aerospace, and electronics.

- Q:The aluminum panel is the cart, ordinary nylon plate, the wheel is not conductive wheel, why use aluminum surface will be static, but not in the nylon plate, not easy to produce electrostatic in high resistance material?

- To protect its surface finish!These thin film aluminum surface coverage of excellent conductivity and it is insulated! Then in normal environment and similar objects formed aluminum will static capacitance effect! This principle is that it can form the electrostatic charge accumulation!

- Q:Ask you, China aluminum plate production factory, supply distribution in the provinces in which the details, please.

- A large share of the domestic market, mainly in Shanghai, Guangdong, Chongqing and other provinces and cities, the other areas are relatively small.From the regional distribution, aluminum production in East China is the highest, followed by South Central China. The provinces and municipalities in Jiangsu, Zhejiang, Guangdong and Chongqing have the highest output.Fengcheng global resource recycling technology development Co., Ltd.

- Q:Can aluminum profiles be used in electrical switchgear manufacturing?

- Yes, aluminum profiles can be used in electrical switchgear manufacturing. Aluminum profiles are lightweight, yet strong and durable, making them an ideal choice for constructing switchgear cabinets. They offer excellent corrosion resistance, which is essential for protecting electrical components from moisture and other environmental factors. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for efficient and cost-effective manufacturing processes.

- Q:Chengdu where to sell aluminum profiles of many businesses?

- Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Extrusion Profiles For Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords