Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Composite Panel Facade Decoration Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

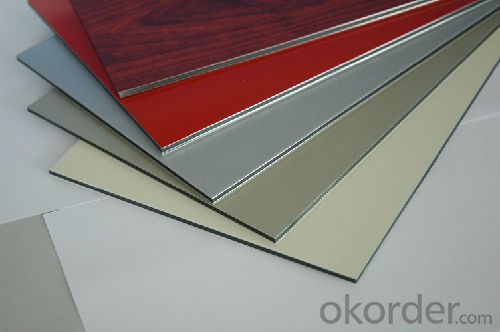

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q:What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on the alloy and temper of the material. However, in general, aluminum sheets have a relatively low impact strength compared to other metals. This is because aluminum is a lightweight material that is not as strong or durable as steel or other alloys. The impact strength of aluminum sheets is typically measured in terms of the energy required to cause the material to fracture or deform. This can be expressed in units such as joules or foot-pounds. While specific values may vary, aluminum sheets generally have an impact strength ranging from 10 to 40 joules or 7 to 30 foot-pounds. It is important to note that the impact strength can be influenced by factors such as thickness, surface condition, and the presence of any surface treatments or coatings. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific tests to determine the impact strength of a particular aluminum sheet.

- Q:How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q:What are the common thicknesses of aluminum sheets used in transportation industry?

- In the transportation industry, aluminum sheets are commonly used for various applications due to their lightweight, durability, and corrosion resistance. The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). For applications such as automotive body panels, which require a balance of weight reduction and structural integrity, aluminum sheets with thicknesses of 0.040 inches (1.02 mm) to 0.063 inches (1.6 mm) are commonly utilized. These thicknesses provide sufficient strength while keeping the weight of the vehicle lower compared to steel counterparts. In the aerospace industry, where weight reduction is of utmost importance, thinner aluminum sheets are often used. Thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are commonly employed in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is worth noting that the specific thicknesses of aluminum sheets used in the transportation industry can vary depending on the specific application, regulatory requirements, and design considerations. Therefore, it is essential to consult the relevant industry standards and specifications for precise information on the preferred thicknesses for different transportation applications.

- Q:Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- i heard plastic is more harmful i read in this article that a chemical found in plastic water bottle was found in this persons blood sample. But it was a small amount where it didnt cause any reactions . when cooking dont use aluminum to cover anything that has tomatoes they cause a bad reaction thats all i know i hope this helps

- Q:is general aluminum sheet fire-proof?

- nonfireproof

- Q:Can aluminum sheet be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheet as a viable option. Aluminum, known for its commendable thermal conductivity attributes, is frequently employed as a material for heat sinks. Its lightweight nature, cost-effectiveness, and resistance to corrosion contribute to its popularity. With the ability to easily mold aluminum sheet into diverse shapes and sizes, it becomes suitable for a range of heat sink designs. The flat and thin composition of aluminum sheet aids in effective heat dissipation by expanding the available surface area for heat transfer. Moreover, aluminum can be readily machined or extruded to produce fins, further enhancing the heat dissipation capabilities of the heat sink. Overall, due to its myriad advantages, aluminum sheet stands as a favored choice for heat sinks in a multitude of applications, encompassing electronics, computers, LED lights, and automotive components.

- Q:How is the strength and durability of aluminum sheets determined?

- The strength and durability of aluminum sheets are determined through various tests and measurements such as tensile strength, hardness, impact resistance, and corrosion resistance. These tests help evaluate the ability of the aluminum sheets to withstand external forces, deformation, wear and tear, and environmental factors. Additionally, the composition and manufacturing process of the aluminum sheets also play a crucial role in determining their strength and durability.

- Q:Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q:What does aluminum plate "3003-H24" mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q:I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Aluminium is and element. An oxide is the result of a substance reacting with oxygen. The properties are completely different for elements and oxides.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords