Aluminium Coil Sheet for Roofing Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

If your roof exhibits any of the above symptoms—or if your roof is simply old—The Aluminum Company will gladly examine your roof as a courtesy to help you determine whether it can be repaired or needs to be replaced. This service call is without any cost or obligation to you.

3. Feature of Aluminum

A new Owens Corning or CertainTeed roof will protect and beautify your home for many years to come. And it will add substantial resale value to your biggest lifetime investment, your home. Choose your roof’s level of durability - 15, 20 or 30 years

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

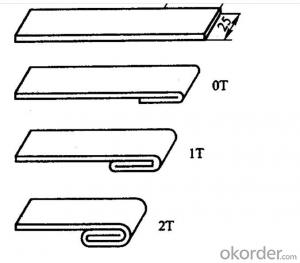

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils are used in the manufacturing of appliances as a key component in the production of heat exchangers. These coils are utilized for their excellent thermal conductivity, which enables efficient heat transfer between the appliance and its surroundings. The coils are shaped into a specific design and then integrated into appliances such as refrigerators, air conditioners, and heating systems to facilitate the cooling or heating process.

- Q:I have my brother's old wooden crutches but i see everyone using aluminum and i have the option to get aluminum ones. Is there any reason why they'd be better then my wooden ones?

- Aluminum might be lighter. As long as the crutches are in good shape and they are appropriately sized for you I say use what you've got.

- Q:Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- You can use water and soap. Aluminum does not rust and will not be harmed by water. Happy washing

- Q:Are aluminum coils suitable for chemical processing applications?

- Yes, aluminum coils are suitable for chemical processing applications. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it an ideal choice for various chemical processes. It can withstand different chemicals and acids, and its lightweight nature allows for easy handling and installation. Additionally, aluminum coils provide good heat transfer and can be easily formed into various shapes, making them versatile for different chemical processing requirements.

- Q:Today at my school I was messing with this sketch thingy, the one with 2 knobs to twist up or down to draw, my friend decided to break it and when we broke it, this silver dust called aluminum powder got on my hands, I never knew it was dangerous cause your see, we never read the manual we just found it. About 3 minutes later he pointed to my hand and I saw blood. It kinda stung.

- The aluminum powder found in an Etch-a-Sketch will not cut you, it's much too small. In fact it's so small you could only see it's edges under a high powered microscope. The cut was most likely caused by jagged glass/plastic when you broke the Etch-a-Sketch open. It's not unusual to cut yourself and not realize until someone else sees you're bleeding.

- Q:Can aluminum coils be used for food processing equipment?

- Yes, aluminum coils can be used for food processing equipment. Aluminum is a popular material choice for its excellent heat transfer properties, corrosion resistance, and lightweight nature. It is commonly used in the construction of food processing equipment such as heat exchangers, evaporators, and condensers.

- Q:How are aluminum coils cut to length?

- Aluminum coils are typically cut to length using a process known as shearing or slitting. Shearing involves using a set of sharp blades to cut the coil into multiple shorter lengths. This method is commonly used for thicker aluminum coils. Slitting, on the other hand, is a process in which the coil is passed through a set of rotating circular knives that cut the coil into narrower strips of the desired width. This method is often used for thinner aluminum coils. Both shearing and slitting processes can be manual or automated, depending on the scale of production and the specific requirements of the project. Automated cutting machines are commonly used for large-scale production as they offer higher precision and faster cutting speeds. It is important to note that during the cutting process, the coil is often uncoiled and fed through the cutting machine. Once the desired length or width is achieved, the cut aluminum pieces are then collected, bundled, and prepared for further processing or distribution.

- Q:Can aluminum coils be welded or joined?

- Yes, aluminum coils can be welded or joined. Aluminum welding involves melting the edges of the coils and fusing them together using a welding technique such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Aluminum can also be joined by other methods like brazing or soldering.

- Q:Are aluminum coils suitable for high-strength applications?

- Aluminum coils are generally not suitable for high-strength applications due to their relatively low tensile strength compared to other materials such as steel. Aluminum has a lower strength-to-weight ratio and is more prone to deformation under high loads. However, there are specific alloys of aluminum that have been developed to enhance their strength, such as the 7000 series aluminum alloys, which can offer higher strength levels. These alloys are commonly used in aerospace and automotive industries for their lightweight properties and moderate strength. Nevertheless, for applications requiring the utmost strength, steel or other high-strength materials are usually preferred over aluminum coils.

- Q:Are aluminum coils suitable for electrical transformer applications?

- Yes, aluminum coils are appropriate for use in electrical transformer applications. Aluminum coils possess several advantages over traditional copper coils when utilized in transformers. To begin with, aluminum is a lightweight metal, making it easier to handle and transport. This is particularly advantageous for large transformers where reducing weight is desired. The lightweight nature of aluminum coils also facilitates easier installation and maintenance. Secondly, aluminum exhibits excellent electrical conductivity, albeit not as conductive as copper. However, aluminum coils can compensate for lower conductivity by employing larger wire sizes or increasing the number of turns. This ensures that the transformer operates efficiently and effectively. Moreover, aluminum has a higher thermal conductivity compared to copper. Consequently, aluminum coils can dissipate heat more efficiently, which is crucial for the proper functioning and longevity of transformers. This increased heat dissipation aids in reducing the transformer's operating temperature, thereby enhancing its overall performance. Furthermore, aluminum serves as a cost-effective alternative to copper. Generally, aluminum is less expensive than copper, making it a more economical option for transformer manufacturers. This cost advantage can be particularly significant in large-scale transformer production. However, it is important to note that there are certain considerations to be mindful of when utilizing aluminum coils in transformer applications. Aluminum coils are more susceptible to oxidation and necessitate proper insulation to prevent corrosion. Additionally, aluminum coils may exhibit slightly higher electrical losses compared to copper coils, although advancements in design and manufacturing techniques have mitigated this concern. In conclusion, aluminum coils are indeed suitable for use in electrical transformer applications. They offer benefits such as lightweight construction, excellent electrical conductivity, superior thermal conductivity, and cost-effectiveness. However, it is crucial to implement proper insulation and preventive measures to address any potential challenges associated with aluminum coils, ensuring optimal performance and durability of the transformers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Coil Sheet for Roofing Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords