Aluminium Circle for Deep Drawing Aluminium Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

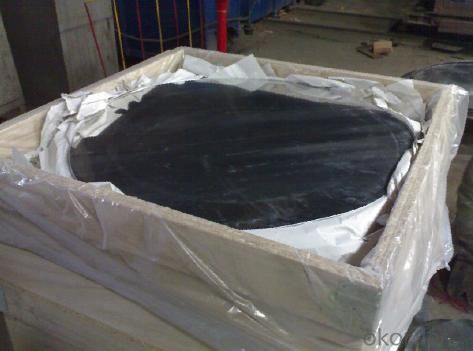

1.Structure of Aluminium Circle for Deep Drawing Aluminium Cup

Aluminium Circle for Deep Drawing Aluminium Cup is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Circle for Deep Drawing Aluminium Cup

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Are the aluminum sheets suitable for manufacturing automotive parts?

- Yes, aluminum sheets are suitable for manufacturing automotive parts. Aluminum is lightweight, corrosion-resistant, and has excellent strength-to-weight ratio, making it an ideal material for automotive components. It offers flexibility in design, allows for fuel efficiency, and helps improve overall vehicle performance.

- Q:What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q:Are aluminum sheets non-magnetic?

- Yes, aluminum sheets are non-magnetic. Aluminum is not a ferromagnetic material, which means it does not have strong magnetic properties. It is classified as a paramagnetic material, which means it has a weak response to magnetic fields. Therefore, aluminum sheets do not attract or hold a magnet.

- Q:I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Bad idea, it will corrode. Better are pool rails made from steel and powder coated in white, or light, not chromed, so you don't get burned. You're welcome!!

- Q:Are aluminum sheets resistant to staining?

- Indeed, staining is not a concern when it comes to aluminum sheets. This is due to the formation of a natural oxide layer on the surface of aluminum when it is exposed to air. The presence of this oxide layer serves as a safeguard, effectively preventing both staining and corrosion. Nevertheless, it is worth mentioning that extended contact with specific chemicals or acidic substances can still result in discoloration or staining on aluminum sheets. To maintain the impeccable appearance and durability of aluminum sheets, it is advisable to engage in regular cleaning and maintenance practices.

- Q:What are the different methods of surface coating aluminum sheets?

- There are several methods of surface coating aluminum sheets, each with its own advantages and applications. The most commonly used methods include anodizing, powder coating, and painting. Anodizing is a process that creates a durable and corrosion-resistant layer on the aluminum sheet's surface. It involves immersing the sheet in an electrolyte solution and passing an electric current through it. This creates an oxide layer that can be dyed to achieve various colors. Anodized aluminum sheets are commonly used in architectural applications, as well as in the automotive and aerospace industries. Powder coating is another popular method that involves electrostatically applying dry powder onto the aluminum sheet's surface. The sheet is then heated, causing the powder to melt and form a durable and protective coating. Powder coating provides excellent resistance to chemicals, UV rays, and harsh weather conditions. It is commonly used in industries such as construction, automotive, and electronics. Painting is a traditional method of surface coating aluminum sheets, where a liquid paint is applied onto the surface using brushes, rollers, or spray guns. This method allows for a wide range of colors and finishes to be achieved. Painted aluminum sheets are commonly used in applications where aesthetics and customization are important, such as signage, architectural facades, and interior design. Other methods of surface coating aluminum sheets include cladding, laminating, and adhesive bonding. Cladding involves attaching a different material, such as stainless steel or copper, to the aluminum sheet's surface. Laminating involves bonding a protective film onto the sheet's surface to enhance its durability and appearance. Adhesive bonding involves applying a layer of adhesive onto the sheet's surface and then bonding a different material or coating onto it. Overall, the choice of surface coating method for aluminum sheets depends on the specific requirements of the application, including factors such as durability, aesthetics, corrosion resistance, and cost.

- Q:Do 101 aluminum sheets have any specific fire resistance properties?

- Yes, 101 aluminum sheets have specific fire resistance properties. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand high temperatures before it starts to melt. Additionally, aluminum has a low combustion point, which means it does not readily catch fire. In case of a fire, aluminum sheets act as a barrier, preventing the spread of flames. Moreover, when aluminum does burn, it forms a protective oxide layer on its surface, which further inhibits the progress of the fire. However, it is important to note that while aluminum has fire-resistant properties, it is not completely fireproof and can still be damaged or deformed by intense heat.

- Q:I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- There are no special cracks in the aluminum bars, such as 1 of the heat distortion, 3 of the metallurgical quality, 2 of the solid solution system, the reasonable analysis of the crack location and appearance

- Q:Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q:What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- I have considerable experience with adhesives of all types and for your project would suggest either 3M's Scotch Weld DP 420 or Loctite's Epoxy Weld bonding compound. Both are two part formulas and are good for bonding aluminum. Hope that helps.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Circle for Deep Drawing Aluminium Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords