Aluminium Checker Plate/ Tread Plate Used for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

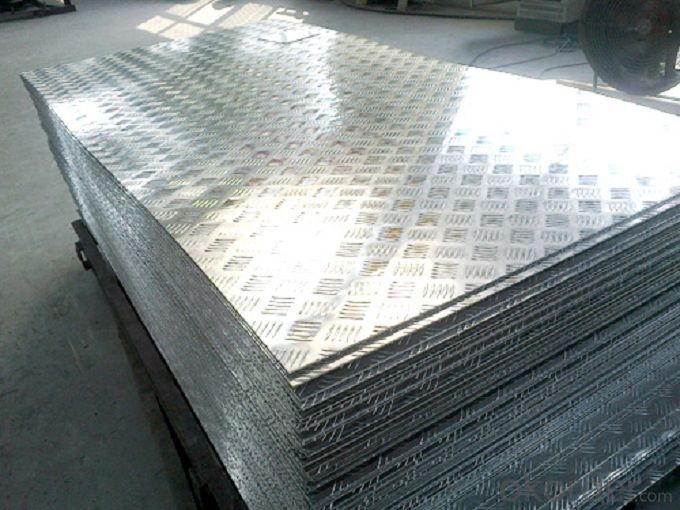

Aluminium Checker Plate/ Tread Plate Used for Stairs

l Product Description

1) Alloy: 1050. 1200, 1100, 3003, 5052, 5754

2) Temper: H111, H112, O, H14, H24, H32

3) Thickness: 0.8mm to 10mm

4) Width: 100mm to 2300mm, Length: up to 11 Meter,

5) Patterns: Two bar,three bar, Five bar and diamond plate

6) Use: Refrigeration floor, Truck floor, flooring, stairs, indoor and outdoor decoration

l Packaging & Delivery

Packaging detail: Standard seaworthy export packing, wooden pallets with plastic protection for sheets

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is highly resistant to corrosion and has excellent marine-grade properties, making it a suitable material for various marine applications such as boat hulls, decks, and structures.

- Q:(given the fact that specific gravity of aluminum is 2.7)1. What is its volume?2. The ingot is suspended from a rope and totally immersed in water. What is the tension in the rope (the apparent weight of the ingot in water)?

- first find the volume of your aluminium. youll need this when analyzing the bouant force F(b). the sg of aluminum is 2.7 and the density of water is 1000 kg/m^3 so the density of aluminum is 2.7x1000=2700kg/m^3. the mass is 71N/g = 7.237512742 kg. so volume of our piece of aluminum = mass/density = 0.0026805603 m^3 now analyze the forces being applied to the system. There are three, the force of gravity F(g), the buoyant force F(b) and the tension T. Tension and buoyant force push up, gravity pulls down. the system will be at rest since the rope is holding it at rest. so T + F(b) - F(g) = 0 T + (Volume aluminum X density water X g) - (MAss of aluminum x g) = 0 T + (0.0026805603x1000x9.81) - (71 N (given in problem)) = 0 Solving for T, T = 44.70370346 N = 45 N using sig figs.

- Q:Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q:How does the surface finish of aluminum sheet affect its cleaning requirements?

- The cleaning requirements of aluminum sheet are significantly influenced by its surface finish. Various surface finishes, such as mill finish, brushed finish, or anodized finish, can impact how dirt, grime, and other contaminants adhere to the surface. Smooth and polished surface finishes like brushed or anodized are generally more resistant to dirt and stains, making them simpler to clean. These finishes have a lower surface roughness, resulting in fewer areas for dirt particles to stick to. As a result, they can be effectively cleaned using gentle cleaning solutions or even just water and a soft cloth. Conversely, aluminum sheets with a mill finish or a rougher surface may require more rigorous cleaning methods. The higher surface roughness of these finishes can create more areas for dirt and grime to become trapped, making it more difficult to remove them with basic cleaning techniques. In such cases, more aggressive cleaning solutions or abrasive cleaning tools may be necessary to eliminate stubborn stains or dirt particles. It should be noted that the specific cleaning requirements for aluminum sheet also depend on the type and severity of the contaminants present. For example, if the aluminum sheet comes into contact with harsh chemicals or corrosive substances, special cleaning methods may be needed to ensure complete removal and prevent any potential damage. In conclusion, the surface finish of aluminum sheet directly affects the cleaning requirements. Smoother and polished finishes are generally easier to clean due to their lower surface roughness, while rougher finishes may require more rigorous cleaning methods. Understanding the surface finish of aluminum sheet is crucial in determining the most suitable cleaning techniques to maintain its appearance and functionality.

- Q:What are the different thicknesses available for aluminum sheet?

- Aluminum sheets come in various thicknesses, spanning from very thin to thick. The thickness of these sheets is measured either in gauge or millimeters (mm), with each gauge denoting a specific thickness. The prevalent gauges for aluminum sheets are 22, 24, 26, 28, 30, and 32, corresponding to thicknesses ranging from 0.0254 mm to 0.635 mm. Moreover, thicker gauges, such as 16 gauge (1.29 mm) or even more substantial ones, can be found for specialized applications. The preferred thickness of an aluminum sheet is determined by its intended use. Thinner sheets are often utilized for lightweight purposes, including electronics or packaging, while thicker sheets are more suitable for structural or industrial needs.

- Q:3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- Attached: O status: fully annealed to obtain the lowest strength of the processing products. 8 state: hard working state (9)

- Q:Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

- Q:What are the different methods for finishing the edges of aluminum sheets?

- There are several methods for finishing the edges of aluminum sheets, depending on the desired outcome and application. One common method is edge trimming, which involves removing excess material from the edges of the sheet to achieve a smooth and straight edge. This can be done using various tools such as shears, saws, or routers. Another technique is edge deburring, which is used to remove any sharp or rough edges left after cutting. This is often done using sanding or grinding tools to smooth out the edges and create a more polished finish. Additionally, edge rolling is a method used to create rolled or rounded edges on aluminum sheets. This can be achieved through a rolling machine that applies pressure to the edges, bending them to the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to create custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that can enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option to consider. This process involves applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps to protect the edges from corrosion or other damage. Overall, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific requirements of the project.

- Q:What are the different types of finishes used for decorative aluminum sheet?

- There are several different types of finishes that can be used for decorative aluminum sheet to enhance its appearance and provide added protection. Some of the most common finishes include: 1. Mill finish: This is the standard finish that aluminum sheets have when they come straight from the mill. It has a smooth, shiny appearance but lacks any additional treatments or coatings. 2. Anodized finish: This finish involves an electrochemical process that creates a durable, corrosion-resistant layer on the surface of the aluminum. Anodized finishes can be clear or colored, and they provide a decorative, matte appearance. 3. Brushed finish: Also known as satin finish, this type of finish involves brushing the aluminum sheet with a fine abrasive material to create a pattern of fine lines or scratches. It gives the sheet a textured, non-reflective surface that hides any imperfections. 4. Polished finish: This finish involves polishing the aluminum sheet with a series of abrasive materials to create a smooth, reflective surface. It gives the sheet a shiny, mirror-like appearance and is often used for decorative purposes. 5. Painted finish: Aluminum sheets can also be painted with various types of coatings to provide different colors and finishes. These coatings can be applied through techniques such as powder coating, liquid painting, or coil coating, and they offer both decorative and protective benefits. 6. Embossed finish: In this type of finish, the aluminum sheet is pressed with a pattern or design to create a three-dimensional surface. Embossed finishes can vary in depth and detail, and they add texture and visual interest to the sheet. These are just a few examples of the different types of finishes used for decorative aluminum sheet. Each finish offers its own unique look and benefits, allowing for a wide range of design possibilities.

- Q:What is the typical fatigue strength of aluminum sheets?

- The typical fatigue strength of aluminum sheets can vary depending on various factors such as the alloy, heat treatment, thickness, surface condition, and the specific application. However, in general, the fatigue strength of aluminum sheets falls within the range of 50-70% of their ultimate tensile strength.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Checker Plate/ Tread Plate Used for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords