Aluminium Cast Slab not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Cast Slab not Alloyed in Coil Form Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Cast Slab not Alloyed in Coil Form:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

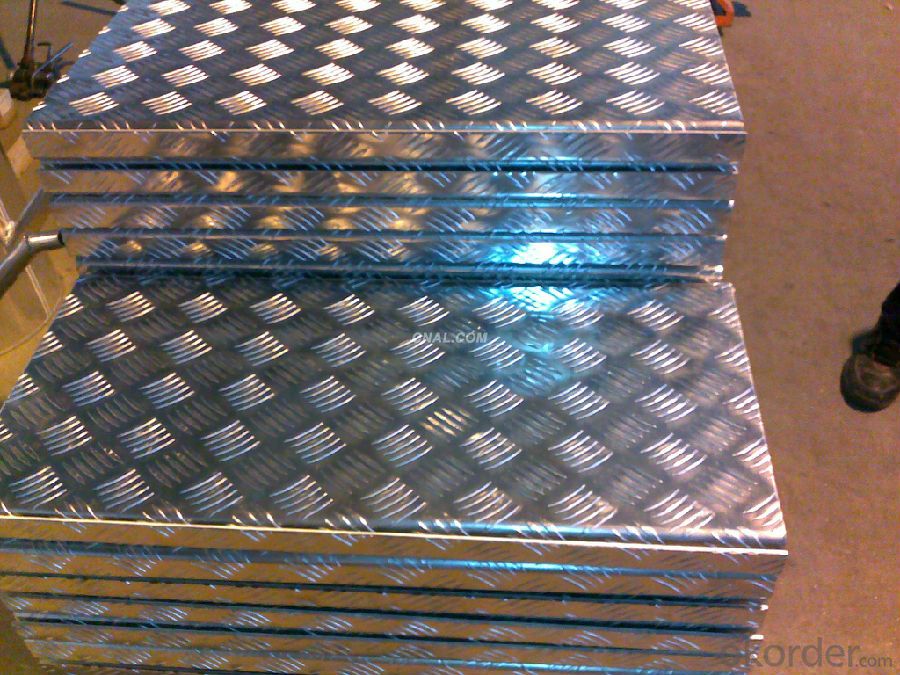

Images of the Aluminium Cast Slab not Alloyed in Coil Form:

Aluminium Cast Slab not Alloyed in Coil Form Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- A section of properties in CAD labeled dynamic block, the section area and mark block association graph can be easily calculated, section area, surface area, weight theory, and the setting up of a variety of materials such as aluminum options.

- Q:How do aluminum profiles perform in seismic or earthquake-prone areas?

- Aluminum profiles have proven to be highly effective in seismic or earthquake-prone areas due to their unique properties. The lightweight nature of aluminum makes it a popular choice for construction in such areas as it reduces the overall weight of the structure, thus minimizing the potential for collapse during an earthquake. Additionally, aluminum possesses excellent ductility, meaning it can deform under stress without fracturing, which allows it to absorb and dissipate the energy generated by seismic activity. Moreover, aluminum profiles have high strength-to-weight ratio, allowing them to withstand the dynamic forces exerted during an earthquake. This strength, combined with the material's corrosion resistance, makes aluminum profiles particularly suitable for seismic areas where the risk of structural damage is heightened. Furthermore, aluminum is a highly malleable material, making it easy to shape and fabricate into various structural components. This flexibility allows for the creation of customized designs that can withstand seismic forces. Additionally, aluminum profiles can be easily bolted or welded together, providing a secure and reliable connection that further enhances the structural integrity of the building. It is important to note that the performance of aluminum profiles in seismic areas also depends on the overall design and construction techniques used. Proper engineering practices, such as incorporating seismic bracing systems or using specialized connectors, can further improve the performance of aluminum structures during earthquakes. Overall, due to its lightweight, ductile, strong, and corrosion-resistant properties, aluminum has proven to be a reliable and effective material for use in seismic or earthquake-prone areas. When appropriately designed and constructed, aluminum profiles can significantly enhance the safety and resilience of structures in these challenging environments.

- Q:Can aluminum profiles be used in the construction of data centers?

- Data centers can utilize aluminum profiles for construction purposes. The utilization of aluminum profiles in this industry offers numerous benefits. To begin with, aluminum possesses a combination of lightweight and sturdy properties, rendering it an excellent material for constructing structures that require the capacity to withstand heavy loads. Considering that data centers often accommodate racks of servers and other equipment, the use of aluminum profiles can provide the necessary strength without adding excessive weight. Moreover, aluminum profiles offer extensive customization options and can be easily fabricated to meet specific design requirements. This flexibility enables efficient space utilization within a data center, as the profiles can be tailored to fit the facility's layout and dimensions. Furthermore, aluminum exhibits resistance to corrosion, a crucial attribute in the data center environment where equipment produces heat and humidity levels can be high. By employing aluminum profiles, the risk of rust and corrosion is minimized, thereby ensuring the infrastructure's longevity and reliability. Additionally, aluminum is an environmentally sustainable and recyclable material, aligning with the increasing demand for eco-friendly construction practices. The utilization of aluminum profiles in data center construction contributes to reducing the facility's carbon footprint. In conclusion, due to their strength, customization capabilities, corrosion resistance, and sustainability, aluminum profiles can indeed be employed in the construction of data centers.

- Q:How are aluminum profiles insulated?

- Aluminum profiles are typically insulated using a thermal break system. This involves placing a non-conductive material, such as polyamide or polyurethane, between the inner and outer sections of the aluminum frame. This insulation helps to reduce heat transfer and improve energy efficiency in buildings.

- Q:Can aluminum profiles be used for electrical cabinets?

- Indeed, electrical cabinets can employ aluminum profiles. Aluminum, a material that is both lightweight and sturdy, exhibits outstanding electrical resistance and thermal conductivity. Its durability and efficient heat dissipation make it a frequent choice for electrical cabinets. Aluminum profiles provide a robust structure for these cabinets, facilitating the effortless installation of wiring and electrical components. Moreover, aluminum profiles can be readily tailored and modified to meet precise design specifications, rendering them an optimal selection for electrical cabinets.

- Q:How do aluminum profiles perform in terms of dimensional stability?

- The excellent dimensional stability of aluminum profiles is widely recognized. This stability is attributed to the inherent characteristics of aluminum, including its low coefficient of thermal expansion and its high strength-to-weight ratio. As a result, these profiles are able to maintain their shape and dimensions even when subjected to varying temperatures and loads. This reliability makes them a preferred choice for industries such as construction, automotive, and aerospace, where precise and consistent dimensions are crucial. Moreover, the extrusion process allows for the production of aluminum profiles with precise tolerances, further enhancing their dimensional stability. All in all, aluminum profiles deliver outstanding performance in terms of dimensional stability, ensuring that the desired specifications remain intact over time.

- Q:Are aluminum profiles suitable for exhibition kiosks?

- Indeed, exhibition kiosks greatly benefit from the use of aluminum profiles. With its lightweight and durable nature, aluminum proves to be the ideal material for constructing kiosks that are easily portable and transportable. Its robustness ensures the creation of stable and reliable structures, guaranteeing the safety of both exhibitors and visitors. Moreover, the versatility of aluminum profiles allows for effortless customization and assembly, granting flexibility in design and layout. In addition, their sleek and contemporary appearance enhances the overall aesthetics of the exhibition kiosk. Furthermore, the corrosion-resistant properties of aluminum make it suitable for both indoor and outdoor use, even in challenging environmental conditions. Ultimately, the exceptional combination of versatility, durability, and aesthetic appeal makes aluminum profiles an outstanding choice for exhibition kiosks.

- Q:What are the different tolerance levels for aluminum profiles?

- The tolerance levels for aluminum profiles can vary depending on the specific application and requirements. However, some common tolerance levels for aluminum profiles include dimensional tolerances, such as length, width, and thickness variations, as well as straightness, flatness, and surface finish tolerances. These tolerances ensure the desired precision and consistency in the manufacturing and assembly of aluminum profiles.

- Q:or what is the difference between the national standard aluminum profile and the European standard aluminum profile, preferably with pictures? Thank you

- The difference between national standard aluminum profile and European standard aluminum profile:Cross section four angles are different: national standard, four angles are right angle, European standard four angles have radian;The shape of the groove is not the same: GB groove is square, European standard slot is obtrapezoid;The rice is different in weight: the national standard is relatively heavy, and the European standard is relatively light.The fittings and installation methods used are different.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Cast Slab not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords