Aluminium Alloy Treadplate and Checker Plate for Floor, Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Tread Plate

l Production Introduction

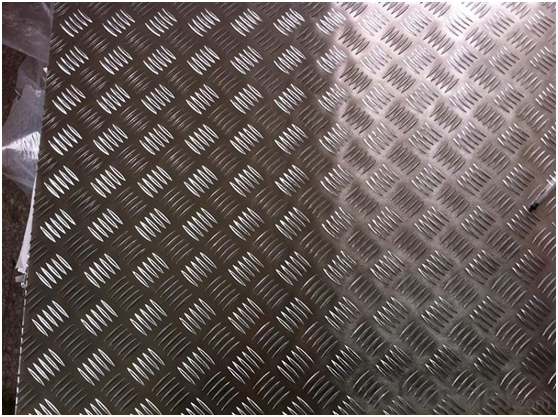

1. Commodity: Aluminium Alloy Treadplate and Checker Plate for Floor, Step

2. Alloy No.: 1050 1060 1100 3003 3004 3104 3005 3105 5005 5052 5754 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

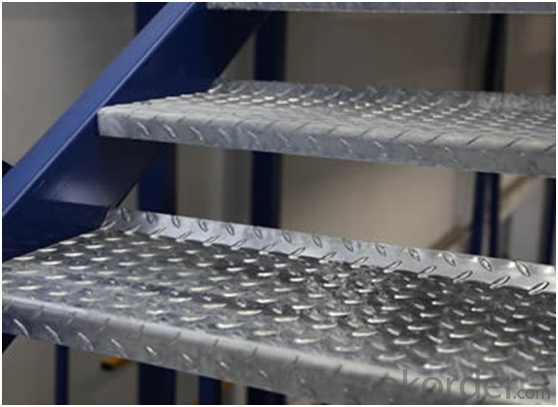

4.Application:

1) air plane, refrigerators, buses,

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

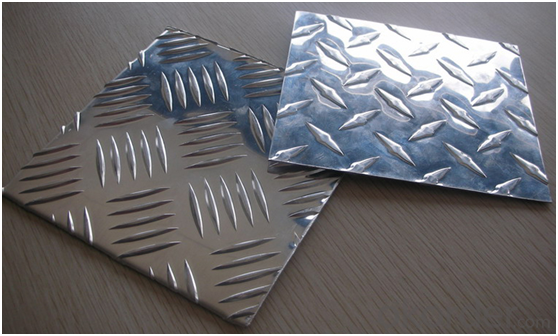

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium treadplate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:Can 101 aluminum sheets be bent without cracking or breaking?

- If proper techniques are used, it is possible to bend 101 aluminum sheets without cracking or breaking them. Aluminum 101 is an alloy that is relatively soft and easily malleable, which makes it suitable for bending. However, it is important to take into account the thickness of the sheets and the radius of the bend. Thicker sheets may require more force to bend, which increases the risk of cracking. Additionally, sharp bends with a small radius can also lead to cracking. To avoid this, it is recommended to use a bending machine or tool specifically designed for aluminum bending. By doing so, it ensures an even distribution of pressure and minimizes the risk of cracking or breaking. In conclusion, although 101 aluminum sheets can usually be bent without any problems, it is essential to use the correct techniques and consider the specific parameters in order to prevent any potential damage.

- Q:What are the different grades or alloys of aluminum available for sheets?

- Aluminum sheets come in various grades and alloys, each with its own unique properties. Grade 3003, for example, is widely used and offers good corrosion resistance and moderate strength. It finds applications in general sheet metal work, cooking utensils, signage, and chemical equipment. On the other hand, grade 5052 is known for its excellent corrosion resistance and high strength. It is often utilized in marine applications like boat hulls and components, as well as aircraft parts and transportation equipment. Grade 6061 is a versatile aluminum grade that combines strength, weldability, and machinability. It is commonly chosen for structural components such as frames, railings, and automotive parts. It is also frequently employed in the architectural field for construction purposes. Apart from these grades, there are numerous specialized aluminum alloys available for specific applications. These alloys may possess enhanced characteristics like improved strength, heat resistance, or electrical conductivity. Examples of such alloys include 2024, 7075, and 6063. When choosing the appropriate aluminum sheet grade or alloy, it is crucial to consider factors such as desired strength, corrosion resistance, formability, and specific application requirements. Seeking advice from a knowledgeable supplier or expert can ensure the correct grade of aluminum is selected for the intended usage.

- Q:How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, it is essential to use a barrier or protective coating between the aluminum and concrete surfaces. This can be achieved by applying a suitable paint, epoxy coating, or a non-conductive membrane to isolate the aluminum from direct contact with the concrete. Additionally, using corrosion-resistant fasteners made of stainless steel or other compatible materials can further prevent the occurrence of galvanic corrosion. Regular inspections and maintenance are also crucial to identify and address any potential corrosion issues promptly.

- Q:Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q:Are aluminum sheets suitable for laser cutting?

- Indeed, laser cutting is a suitable method for aluminum sheets. Aluminum, which possesses exceptional reflective properties, high thermal conductivity, and a low melting point, is extensively employed in laser cutting operations. These remarkable attributes render it a prime candidate for being sliced by a laser beam. Laser cutting ensures accurate and neat incisions on aluminum sheets, enabling the effortless realization of intricate patterns and intricate forms. Moreover, laser cutting for aluminum sheets guarantees rapid and efficient processing, delivering enhanced productivity and cost-effectiveness.

- Q:Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q:How do you achieve a mirror-like finish on aluminum sheets?

- To achieve a flawless mirror-like appearance on aluminum sheets, a series of procedures must be undertaken to eliminate any flaws and create a sleek, reflective surface. The crucial steps involved are as follows: 1. Surface preparation: Commence by meticulously cleansing the aluminum sheet to eliminate any dirt, grease, or other contaminants. Utilize a mild detergent and water to accomplish this task. Thoroughly rinse the surface and ensure it is completely dry. 2. Sanding: Employ increasingly finer grades of sandpaper or abrasive pads to eliminate any scratches, oxidation, or unevenness on the aluminum surface. Begin with a coarser grit (around 120-180) and gradually progress to finer grits (up to 1000 or higher) to attain a smoother texture. It is essential to sand consistently in one direction to avoid visible scratches. 3. Polishing compounds: Administer a polishing compound or specialized metal polish designed explicitly for aluminum surfaces. Employ a soft cloth or a buffing wheel to apply the polish and work it into the surface. Apply gentle pressure and distribute the polish evenly by executing circular motions. Repeat this step until the desired level of shine is achieved. 4. Buffing: Utilize a buffing wheel, preferably composed of felt or cotton, to further enhance the luster. Apply a small quantity of a high-quality polishing compound to the wheel and meticulously buff the aluminum sheet in a consistent manner. Employ circular motions and maintain an unwavering, even pressure. 5. Final polishing: To attain an impeccable mirror-like finish, employ a specialized aluminum polish or a metal finishing compound. Apply a small amount onto a clean cloth and gently rub the surface using circular motions. This final step aids in eliminating slight scratches or imperfections, augmenting the brilliance of the aluminum sheet. Remember to meticulously cleanse the aluminum sheet after each step to eliminate any residue or excess polish. Furthermore, always adhere to the manufacturer's instructions when utilizing specific polishing compounds or tools as they may provide specific guidelines for optimal outcomes. By diligently following these steps, you can achieve a mirror-like finish on aluminum sheets, transforming them into highly reflective surfaces that are visually captivating and functionally efficient.

- Q:Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- I am not sure where some of these posts came from, but from someone like myself who road cycles 6000 to 8000 miles per year and has a 3 year old carbon fiber frame, I have never had any problems with my frame... I have never heard of any carbon bike breaking unless it was in some MAJOR crash... the same crash that would destroy almost any bike (except cromealloy steel)... That being said, carbon frames are usually the lightest out there, but they can be pricey. Yes, they can be stiffer, but that is a GOOD thing because the power transfer through the drivetrain is better, especially when you have to get up out of the saddle. While riding regularly, especially on the flats, it gives a bit, providing a plush ride. I love my Specialized Roubaix Pro, pretty much everything on the bike is carbon, from the FSA cranks to the Specialized carbon stem... But be prepared to spend at least 3000 bucks to get the bike with good components. Ride safe and have fun!

- Q:Thickness of Aluminum Foil A rectangular sheet ofaluminum foil is 50 centimeters long and 20 centimeterswide, and weighs 5.4 grams. Find the thicknessof the aluminum foil in centimeters

- density Aluminum 2700 kg/m? Volume = 0.5 x 0.2 x d = 0.1d m? where d is thickness 5.4 g = 0.0054 kg 0.0054 kg / 2700 kg/m? = 2.0e-6 m? 2.0e-6 m? = 0.1d m? d = 2.0 e-5 m or 20 ?m or 0.02 mm or 0.002 cm .

- Q:What are the different methods of surface etching for aluminum sheets?

- There are several methods of surface etching for aluminum sheets, each with its own advantages and applications. Some of the most common methods include: 1. Chemical etching: This method involves using a chemical solution to selectively remove a thin layer of aluminum from the surface. The solution typically contains acids or alkaline substances that dissolve the metal, creating a textured or patterned surface. Chemical etching is precise and can achieve intricate designs, making it ideal for decorative or aesthetic purposes. 2. Mechanical etching: Also known as abrasive blasting or sanding, mechanical etching involves using abrasive materials such as sandpaper or wire brushes to physically remove the top layer of aluminum. This method is relatively simple and can be done manually or with the help of machinery. Mechanical etching is commonly used to create a uniform matte finish or to prepare the surface for further treatments, such as painting or coating. 3. Electrochemical etching: This method utilizes an electrical current to selectively dissolve the aluminum surface. The aluminum sheet is immersed in an electrolyte solution, and a direct current is applied through a stencil or mask to create the desired pattern. Electrochemical etching is commonly used for marking or labeling purposes on aluminum sheets, as it can produce clear, permanent, and highly precise designs. 4. Laser etching: Laser etching involves using a high-powered laser to remove the top layer of aluminum, creating a permanent and precise pattern on the surface. This method is highly accurate and can achieve intricate designs with sharp edges. Laser etching is commonly used for industrial applications, such as marking serial numbers, logos, or barcodes on aluminum sheets. 5. Photochemical etching: This method involves using a photosensitive material, known as a photoresist, to create a pattern on the aluminum surface. The aluminum sheet is coated with the photoresist, exposed to UV light through a stencil or mask, and then developed to remove the unexposed areas. The exposed aluminum is then etched away using a chemical solution. Photochemical etching is commonly used for producing high-resolution designs or microstructures on aluminum sheets. Each of these methods has its own advantages, depending on the desired outcome and application. It is important to consider factors such as precision, speed, cost, and complexity when choosing the appropriate surface etching method for aluminum sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Alloy Treadplate and Checker Plate for Floor, Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords