Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

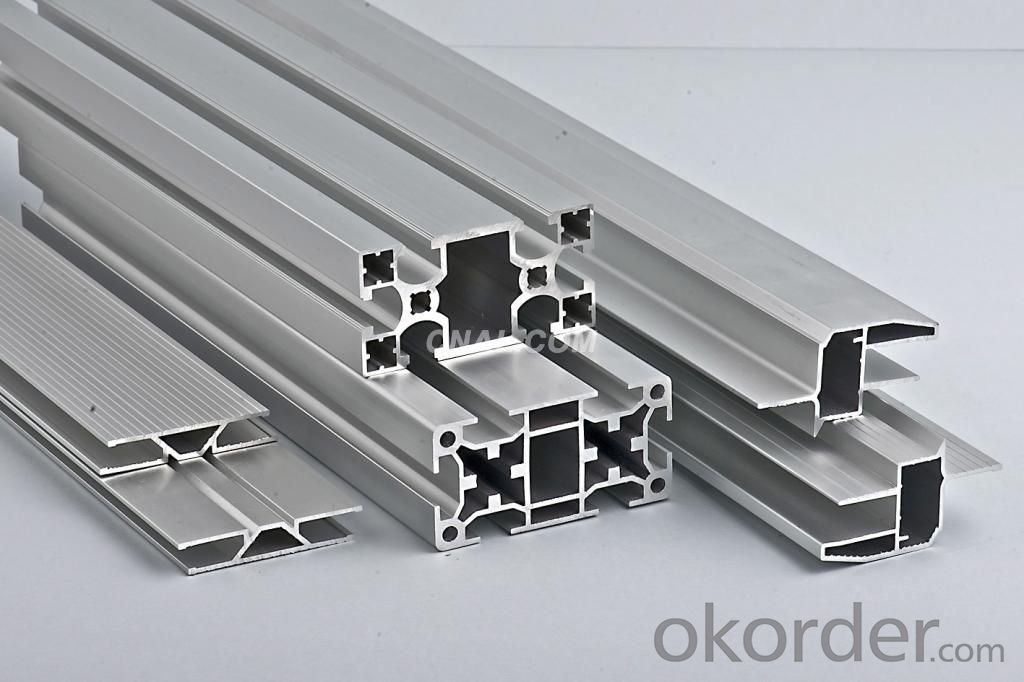

Structure of Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

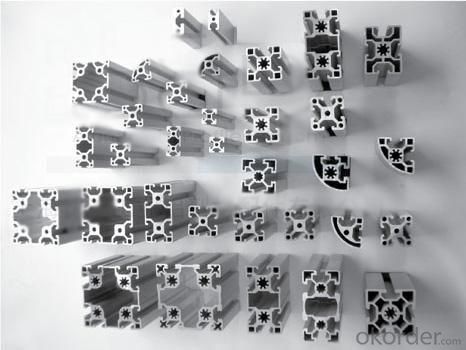

Images of the Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles:

Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Is aluminum sheet recyclable?

- Indeed, aluminum sheet possesses a high recyclability factor. In fact, it ranks among the most sustainable and environmentally conscious materials available. This is due to its unique ability to be recycled endlessly without any compromise to its quality. The process of recycling aluminum sheet involves melting it down until it reaches a liquid state. Interestingly, this process requires far less energy than producing primary aluminum from raw materials. By engaging in the recycling of aluminum sheet, we not only preserve our precious natural resources but also play a crucial role in reducing greenhouse gas emissions and conserving energy. It has been estimated that recycling just one ton of aluminum sheet can save up to nine tons of CO2 emissions. Therefore, embracing the practice of aluminum sheet recycling is not only economically feasible but also a vital step in fostering a sustainable and eco-friendly environment.

- Q:Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q:How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, it is essential to use a barrier or protective coating between the aluminum and concrete surfaces. This can be achieved by applying a suitable paint, epoxy coating, or a non-conductive membrane to isolate the aluminum from direct contact with the concrete. Additionally, using corrosion-resistant fasteners made of stainless steel or other compatible materials can further prevent the occurrence of galvanic corrosion. Regular inspections and maintenance are also crucial to identify and address any potential corrosion issues promptly.

- Q:Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust. This is because aluminum naturally forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. Unlike iron or steel, which can rust when exposed to moisture and oxygen, aluminum does not require any additional coatings or treatments to protect it from rusting. This makes aluminum sheets a popular choice for a wide range of applications, including construction, automotive, and marine industries, where resistance to rust is essential.

- Q:Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes including brushed and polished. These finishes are achieved through various processes that alter the surface texture and appearance of the aluminum sheets. Brushed finishes create a textured pattern by brushing the surface with fine abrasive materials, resulting in a satin-like appearance. On the other hand, polished finishes involve buffing the surface to a high shine by using abrasive compounds or polishing wheels. These different finishes allow for customization and versatile applications of aluminum sheets in various industries.

- Q:What are the different methods of surface coating aluminum sheets?

- There are several methods of surface coating aluminum sheets, including anodizing, powder coating, paint coating, and electroplating.

- Q:Can 101 aluminum sheets be used in architectural cladding?

- Yes, 101 aluminum sheets can be used in architectural cladding. Aluminum is a popular choice for architectural cladding due to its lightweight, durability, and corrosion resistance. The grade 101 aluminum sheets are commonly used in architectural applications as they offer good formability and are easily workable. These sheets can be easily cut, shaped, and joined together to create customized cladding solutions. Additionally, aluminum can be coated or anodized to enhance its appearance and provide additional protection against weathering. Therefore, 101 aluminum sheets are suitable for architectural cladding projects.

- Q:(2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q:Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Krylon is a very tough metal medium and the newer product they have at wal-mart in the paint section is fantastic. I don't know about rustoleum, other than another brand, but you could use a coat of polyutherine matte varnish. You can get this at wal-mart in the paint section or a hardware store. It will seal anything.

- Q:The difference between aluminum plate and aluminum plate

- Aluminum plate is a large piece, the regular width is 90 to 130 centimeters. The aluminum plate is cut aluminum plate, usually according to requirements made several centimeters wide.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords