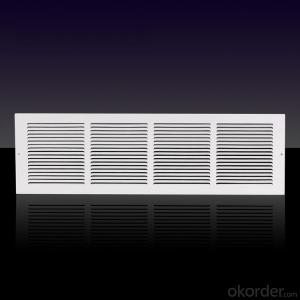

Aluminium Air Diffuer Ceiling Use with Steel Damper

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Air Diffuser

Aluminium Round Diffuser

Supplying Air Diffusers

-Frame Thickness: 1.0mm /0.8mm

-Any Size be customed

-Powder Coated RAL 9010/9016

Usage of Air Diffuser

The grille is suitable for ceilling sidewall, soffit or cill mounting and may be used for supply or extract applications.

Typical installations include offices, shops, hotels and most commercial or industrial buildings.

Available as standard in white polyester powder coat finish.

Other polyester powder coat finishes are also available as an option.

Specification of Air Diffuser

round air diffusers | ||

circular ceiling diffuser | ||

round diffuser | ||

NECK SIZE(mm) | DESCRIPTION OF GOODS | |

Diameter | 100 | 1. Product name: round air diffuser |

Diameter | 125 | 2. Material: aluminum |

Diameter | 150 | 3. Powder coated: standard color, RAL 9010/9016聽 |

Diameter | 160 | 4. Damper with |

Diameter | 200 | 5. reduce the flow resistance and noise. |

Diameter | 250 | 6. The products are easy to install and clean. |

Diameter | 300 | 7.聽 adapt to centrel air-conditioning systems. |

Diameter | 350 | 8. other size/colors available. |

Dimensions,colors,thickness, finished, disigns and other specification can be customized according to customers' request | ||

Products Show

Packing & Shipment

Packing:

PO shrink film bag for each pcs, ourter by export carton

PVC film + 4 plastic protection corners + carton box + closed wooden box optionally.

Shipping:

within 21 days after deposit

Packing:

PO shrink film bag for each pcs, ourter by export carton

PVC film + 4 plastic protection corners + carton box + closed wooden box optionally.

Shipping:

within 21 days after deposit

FAQ:

1, What's size do u have for round type diffuser?

A: We have face size from 150mm to 550mm,neck size from 250mm to 400mm聽

2, Do u still have other types ?

A: Yes, we have round diffuser/ rectangle diffuser/ linear grilles/ baseboard diffusers,etc

3, What's the most early delivery time?

A: Within 25 days for each 40'fcl

- Q:What are the condensers made of?

- Such as solenoid valves, dispensers, dryers, heat collector, fusible plug, pressure controller and other components, they are in order to improve the economy of operation, reliability and safety setting.

- Q:Refrigerators do not cool, compressors do not work, but very hot, what is the reason?

- The temperature of the refrigerator is too high, the internal temperature has reached the set temperature, so it does not start

- Q:What is the function of the air conditioning condenser?

- The high pressure and high temperature refrigerant gas discharged from the compressor enters the condenser coil outside the chamber and is cooled by the airflow outside the fan (about 35 degree C) driven by the fan

- Q:What is the Basic accessories for air conditioners?

- Sight glass,throttle valve,Compressor, evaporator, condenser and expansion valve

- Q:How to repair air conditioning compressor?

- Check the compressor does not start trouble, such as the bottom of the capacitor drum, remove the capacitor, the bottom placed in the plane, such as standing instability, about rocking, then the compressor capacitor must be damaged, can be replaced directly

- Q:What is the function and control of the evaporator and condenser of the air conditioner?

- The evaporator is like the air conditioning will see popsicles popsicles in hot weather

- Q:What are the types of condensers?

- The condenser used in boiler, also called flue gas condenser, can effectively save the production cost, reduce the smoke exhaust temperature of boiler and raise the thermal efficiency of boiler. Boiler operation in line with national standards for energy conservation and emission reduction

- Q:The air-conditioning compressor is stuck. Is there any way to repair it?

- In judging whether the compressor has a cylinder, it is necessary to make a comprehensive judgment according to the running state of the compressor, the working current, the temperature of the suction and exhaust, the temperature of the body, the normal capacity of the starting capacitor and so on

- Q:What's the difference between compressor and air compressor?

- Compressor: a wide range including air compressors, and others, such as oxygen, as the medium, both of which provide pressure, only the medium of compression is different

- Q:What are the risk factors of condensers?

- Combustible components are mainly acetylene and other hydrocarbons, acetylene is the most dangerous, the solubility in liquid oxygen is very low (5.6 * 10-6mg/L), it is easy to precipitate in solid state and cause explosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Air Diffuer Ceiling Use with Steel Damper

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords