Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel

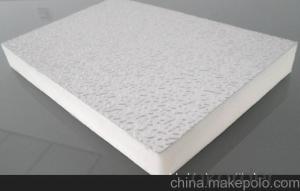

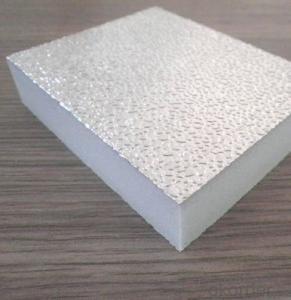

1.Structure of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel

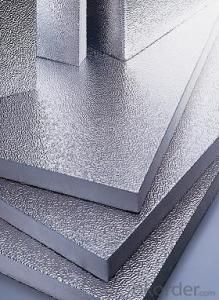

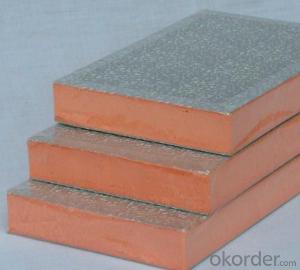

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

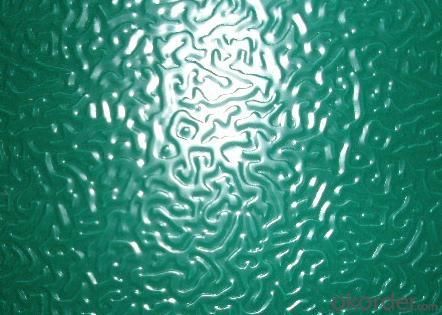

3.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:I found an aluminium foil wraped around a black powder coating from a electrolyte capacitor.Wikipedia : quot; Aluminum electrolytic capacitors are constructed from two conducting?aluminium?foils, one of which is coated with an insulating?oxide?layer, and a paper spacer soaked in?electrolyteThe foil insulated by the oxide layer is the?anode?while theliquid?electrolyte and the second foil acts as thecathode.quot;

- The BEST is made by CHI (it's about $199 for the low end) but you can find some deals onlineHairstylists use it and love it!

- Q:OkayYesterday i posted many questions about thisMy spark plug broke inside the cylinder! I bought some Champion plugs, after only 1,200 they were misfiring i noticed they were extremely worn! So i took them out and replaced them with motorcraftYet on one cylinder the plug broke and, as i tried to remove the remnants of the plugs, the hex came off along with the remainder of the plug, only leaving the thread ring and the gap in the cylinder! I am afraid pieces of metal fell into the cylinder! Not only that, even with an easy out thing i can't remove the old thread! Its lodged in there! The car is a 2001 Ford WindstarAnd in reality i can't afford to have the whole engine taken apartFord engineered these cars so its nearly impossible to access the rear plugs! And champion plugs are a POS! What can i do!gt;!?!

- If there are old socks and/or nylons around the house, wash them and chop them up into little piecesFabric scraps from fleece work well, tooFailing the availablility of those, you can always buy fiberfill at a crafts supplies store.

- Q:how weak is aluminum wiring and how long can it last

- If you can plug an ordinary table lamp in, and the appliance cord holds tight without sagging, the lamp turns on and doesn't flicker or dim, it worksAluminum is not used anymore for branch circuit wiringIf it is still working, leave it alone because the more you mess with al, the closer it gets to failure.

- Q:What is the thickness of foil in mm if a package of aluminum foil contains 50ft squared and weighs 8 oz.?

- According to Wikipedia, the density of aluminum is 2.70 grams per cubic centimeter near room temperatureDisregarding any coatings or additives to the foil, and assuming that it is made from pure aluminum, we can calculate the thickness from the information given and the densityI also assume you mean 50 square feet, not (50 feet)^2, which is 2500 square feetOne inch is 2.54 centimeters, so 50 square feet is 50 (2.54 12)^2 50 30.48^2 50 929.0304 46451.52 cm^2There are 28.3495 grams per ounce, so 8 oz 8 28.3495 226.796 grams Let T the thickness (in cm) of the foil226.796 g / (46451.52 cm^2 T cm) 2.70 g/cm^3 226.796 g / 46451.52 cm^2 2.70 g/cm^3 T cm (226.796 g / 46451.52 cm^2) / (2.70 g/cm^3) T cm T 0.001848 cm T 0.01848 mm So the thickness is 0.01848 millimeters, or 18.48 micrometersNote that this is a reasonable answer for real-world household aluminum foilAccording to Wikipedia, standard household aluminum foil is typically about 0.016 mm thick and heavy duty household foil is about 0.024 mm thick.

- Q:i work a LOT and i have my own apartment so i am the one doing all the grocery shoppinghopefully i'll get a roomate VERY soonthis is my grocery list for two weeks( the things i bought)-Jalapeno kettle cooked chips(big bag)- pack of bacon-carton of eggs-loaf of white breadbox of family size lasagna-freezer/storage slider bags( 16 bags)-slim fast chocalate peanut caramel bars( like 4 dollars per box)- LOVE THESE!!- bag of microvable corn-toilet tissue-little scrubber things to wash dishes with-paper plates-aluminium foil- nail polish remover-napkinsgerm xbox of frozen pizza-orange juice-big jug of juice-greens-small thing of milk-box of cereal(frosted flakes)- ground beef-spaghetti noodles and tomatoe saucegatorade

- Put it in a chilly bin, wrapped in several towels.

- Q:Who can I buy an aluminum radiator core from? I'm trying to make a custom radiator for a tractor and I'm looking for a core that I can tig weld custom endtanks on.

- How much they cost and where to buy them.I know thatGood luck with THAT!

- Q:it has locks and since its the summer it is getting hot in the apartment, would you leave the sceen door that can lock as the only door closed? it has a wooded door too but to let more air flow in the house what would you do? Would you feel comfortable leaving the house for hours if its in a locally known bad area?

- A standard screen door, no, absolutely not, but if you have a Security screen door yesThe difference is the security screen is a heavy gauge metal and is also made to accept a door knob deadboltA standard aluminum screen door is an invitation.

- Q:The water lance I have is shaped like a shepherd's crook, I need to straighten it up a few degrees.

- The best method is to use a tool called a bender used by electricians to form bends and curves in conduitIf you know an electrician you may be able to borrow or rent one from your handy tool rental co nearbyMakes life a lot simpler and avoids oops .

- Q:Explain thouralghy!!

- I am not sure, but I think the chemical you are talking about is a very corrosive base, sodium hydroxide, NaOH, which would react with aluminum to form Al(OH)3 and sodium metalSodium metal is very unstable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords