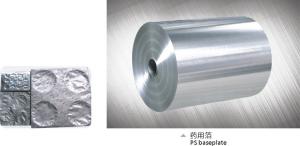

ALUMINIO FOIL PHAMACEUTICAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

farmaceuticos aluminium foil

shiney side HSL against PVC, Dull side Primered for afterwards printing

luminio 20 micrones blister

Temple duro lámina de estructura:

Primer para Imprimir con Laca nitrocelulosa de 1.5gr/m2 + / - 0.5gr

Aluminio duro de 20micrones 54.0gr/m2 + / -8%

Capa de sellado Laca (Código POR-201)

Revestimiento acrílico de vinilo 6gr/m2 + /-1gr

El peso total 60.5gr/m2 + / -8% (28my espesor total de + / -8%)

Descripción del papel de aluminio, dura resistencia, 20my, uno de los lados lacado con laca resistente al calor, el lado que aguanta calor para el sello es lacado para sellar la hoja de PVC rígido y PVDC, en rollos, lisos o impresos, máximo 4 texto en color impresión en rotograbado

Detalles Técnicos: Resistencia a la tracción: más de 150n/mm2

Elongación: 1% -5%

La temperatura de sellado desde 180 hasta 240 grados

Adherencia más de 7.0n/15mm al PVC

A 160 grados, 1 segundo, 4kp/cm2

carretes núcleos (de papel o acero) 76 mm

Anchura máxima de la bobina: 580 mm

Apariencia

Enrollado firme y uniforme, los lados limpio, la diferencia es menos desigual de 2 mm, no tiene ninguna variación obvia o flojo para el núcleo interior, sin gravaciones y cóncavo, el punto reconstruido por 500 no es más que una.

- Q:to come over and cook me some mac and cheese?

- The recipe is telling you how to carmelize the milk in the first sentence after To create toffee fillingI think there is way too much butter listed for the crustUse 6 tablespoons or the crust will be greasy.

- Q:If 15.5g of aluminum are reacted with 46.7g of chlorine gas, then aluminum choloride, AlCl3, is formed.a) Which reactant is in excess?b) Calculate the number of grams in excess?c) Calculate the mass of aluminum chloride produced.Ok, so I figured out the equation is 2Al + 3Cl2 -gt; 2AlCl3I did the work but I got a negative answer for (a), but I don't think that's possible.

- As long as the electrons are on the outside, and the protons and neutrons are somewhere in the nucleus, i don't think it matters

- Q:Why do my Wilton cookie sheets burn everything?

- Use parchment paper for cookies and biscuits, not aluminum foil Your oven's thermostat may be way offIt's not unheard of, especially in electric ovens.

- Q:Well i made some fondant with Crisco All Vegetable shortening, 2lbs of powdered sugar, 1/2 teaspoon of salt, 1tsp of imitation vanilla extract, 1 cup of clear corn syrup and thats it.I put all the ingredients together and just mixed and then it looked like nothing happened so i put it on the stove on quot;highquot; till it looked slimy and then took it out and let it cool till it looked somewhat weird but it looked like gooI wrapped it in some clear foil then aluminum foil and put it in the freezer and thats itWill it taste weird? Did i make it right? Any suggestions?

- i could propose no longer getting a eco-friendly roof by means of fact it is not probably reasonable and environmental it isn't any longer that large the tworeasonable, in evaluation to maximum eco-friendly initiatives, there relatively isn't any return of your cash as quickly as you make investments your capitalEnvironmental, only think of of all the components you are going to could desire to place into itFertilizers interior the soil for no less than the 1st couple years, if not extra, to get all the plant existence began upSoil, that's a non-renewable source by means of fact it could take as much as a minimum of one thousand years to make only 2 inches of stable, fertile soilThen keep in mind all the equipment in contact just to maintain it looking stableSmall automobiles are honestly terrible for the ecosystem (in reality, mowing an everyday sized backyard releases only as many pollution as using a automobile from super apple to CA)i'm no longer thoroughly specific if there are thoughts to eco-friendly roofsin case you may desire to locate some thank you to wrestle the flaws indexed above, i think of eco-friendly roofs could be niceThe decay of plant life/trees take place certainly in nature, and because we are destroying lots of it already, including a eco-friendly roof right here and there won't make lots of a difference (stable or undesirable)Ozone is destroyed interior the direction of the launch of CFCs, halogens, and different such chemical substances, so the decomposition does no longer harm the ozone layer.

- Q:So I'm a little confused on whether or not you add the coefficient when you write the half reactionsFor example:3Cu^+2(NO3)2^-1 + 2Al 2Al^+3(NO3)3^-1 + 3CuThe copper would be reduced because it lost electrons and aluminum would be oxidized because it lost electronsWould the half reactions of copper be 3Cu^+2 + 3e^-1 3Cu or Cu^+2 + 2e^-1 Cu?Also, for aluminum, would it be 2Al 2Al^+3 + 4e^-1 or Al Al^+3 + 3e^-1? Thanks~

- If you do not have a rotisserie, brine the turkey overnight:) Season w sugar, add water to moist:) Place in fridge at least 24 hoursOlive oil, lemon and herbs works just as wellBeer is niceSoy sauce and garlic:)

- Q:please i going to put galic and rosemary just something easy just how to cook them please in oven? fry pan?

- And why, pray tell, do you think of top rate gasoline might boost MPG in a automobile it is not tuned for it? by the form, every physique who says im think to be getting is deluded by using definition; until you rigidity precisely the way the EPA attempt runs you will not get precisely the EPA numbersand you do not; you have already mentioned so(And being a info hound, i might say which you desire a minimum of 5000 miles to make something corresponding to a cost judgment on gasoline mileage, yet then human beings do not desire info; they decide to sense sturdy approximately what they offered.)

- Q:I recently started baking cookies but the parchment paper/cookie sheet is always burnt afterwards (and the bottom of the cookie too)Is it supposed to be like that? Should I use aluminum foil instead?

- Stupid question for u, but r u sure you're using parchment paper and not wax paper? Parchment paper is impregnated w/silicone and generally doesn't burn unless at VERY high temps (i made this mistake myself when i first took up cooking ten yrs ago, i didn't know any better)I wouldn't suggest using aluminum foil tho, u might want to invest in a silpat, or some similar reusable silicone baking mat, they're relatively cheap, and they work great for almost any baking use, not just cookies.

- Q:i can use carboard, aluminium foil, glue, glassi will appreciate any suggestions thank u so much.

- Apple sauce is binding, ask any dr when a child has a stomach virus, apple sauce is part of the BRAT diet, bananas, rice apple sauce and toast, to help clear it upmy son is 2 and a half and recently stopped using Miralax for his severe constipation, he still has trouble now and then, i give him apple juice, i know, apple sauce, apple juice, but there is something in the sauce that's bindingAlso water and vegetables, i also have used clear karo syrup, ask dr 1st! Some kids do get constipated at this age, most is normal, others need medical intervention, like my son; it took 2 weeks to fully clean him out( under the supervision of a specialist)He needs to stay hydrated, will he sit on a potty? sitting helps them get it outMake sure his stomach doesn't get hard, or he's screaming in painA sign of too much back up is, less eating, and he seems miserable and 'dry' looking, my son dehydrated because his liquids were being absorbed by 2, even though drssaid he looked fine and was peeing, he was so dehydrated, he lost 6 lbs, all because the medical community insisted he would go and recoveri would call his dr ans get his advicewarm soapy baths sometimes help tooI would only use miralax if a week ha passed wo anything and if his dr gives the okayMiralax works fast, and can sometimes create diarrhea, depending on the severity, 1 cap a day should be fine until he is cleaned out, if this is a regular occurrence as w my son then I would try miralax once a weekmy sons constipation started at 13 mos until recently at 2 and a halfOnce a week of miralax worked good for him His stools w miralax should be softer and easier to pass, also a pudding texture sometimes is a result also, watch for too loose stools, which creates dehydrationMake sure he drinks plenty of liquidsi would still talk to his Dr.

- Q:Eating utensils?

- YES-YOU CAN ! ! ! ! ! ! ! ! ! I put stainless steel bowls in my 10 year old microwave all the timeHere are some don'ts: 1don't put foil in the microwave 2don't have metal covering the food you are trying to heat 3you can use a metal bowl as long as the lip isn't too big 4don't use forks, meat thermometers, metal utensils 5don't use aluminum pie plates When you put a metal bowl or pan in the microwave for the first time, stand there and be sure it is not going to spark or burnIf it is going to do that, it will do it within the first 15 secondsOnce you have approved a container, you can use it again without much concern.

- Q:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98Please give formula used to solveThanks

- Sodium - Atomic Number: 11 Mass Number: 22.99 Number of Protons: 11 Number Neutrons: 12 Number of Electrons: 11 Hydrogen - Atomic Number: 1 Mass Number: 1.01 Number of Protons: 1 Number of Neutrons: 0 Number of Electrons: 1 Neon: Atomic Number: 10 Mass Number: 20.18 Number of Protons: 10 Number of Neutrons: 10 Number of Electrons: 10 Fluorine: Atomic Number: 9 Mass Number: 19 Number of Protons: 9 Number of Neutrons: 10 Number of Electrons: 9 Uranium Atomic Number : 92 Mass Number: 238.03 Number of Protons: 92 Number of Neutrons: 146 Number of Electrons: 92 Aluminum Atomic Number : 13 Mass Number: 26.98 Number of Protons: 13 Number of Neutrons: 14 Number of Electrons: 13

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALUMINIO FOIL PHAMACEUTICAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords