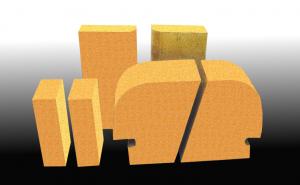

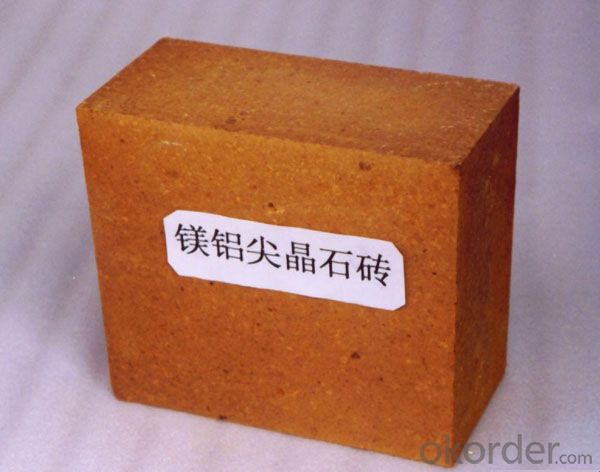

Alumina Spinel Refractory Brick with tough texture and high quality of compression resista

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | magnesite spinel |

| SiO2 Content (%): | 1.2-4 | Al2O3 Content (%): | 6-10 | MgO Content (%): | ≥80 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Model Number: | MA | Brand Name: | CNBM |

| A.P.: | ≤ 17% | Bulk density: | ≥ 2.93 g/cm3 | Cold crushing strength (MPa): | >50 |

| Refractoriness under load (℃): | >1610 | Thermal shock resistance (times): | 3~6 | CaO %: | ≤1.5 |

Packaging & Delivery

| Packaging Details: | in wooden pallets |

| Delivery Detail: | 25 days |

Advantage:

It takes good quality fused magnesite and fused mgo-cr clinker as raw material, formed under high pressure,burned in high temperature. It has character of corrosion resistance.

Type:

We can supply High Alumina Bricks, Fireclay Bricks, Low Porosity Fireclay Bricks, Mullite Bricks, Corundum Bricks, AZS Bricks, Magnesite Bricks, Zircon Bricks,insulating Bricks etc.

Application:

Main using for VOD,AOD,SKF,LF,RH etc. secondary refining furnace.

Specification:

FM-MA80 | FM-MA85 | FM-MA90 | |

MgO (%) | 85 | 88 | 90 |

Al2O3 (%) | 7 | 6.5 | 6.5 |

SiO2 (%) | 4 | 2.4 | 1.2 |

CaO (%) | 1.5 | 1.3 | 1.2 |

Fe2O3 (%) | 1.7 | 1.4 | 1.0 |

Apparent porosity (%) | 17 | 17 | 17 |

Bulk density (g/cm3) | 2.93 | 2.93 | 2.94 |

Cold crushing strength (MPa) | 50 | 50 | 55 |

Refractoriness under load (℃) | 1610 | 1650 | 1700 |

Thermal shock resistance (times) | 3~6 | 3~6 | 3~6 |

- Q:What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q:What is the main component of corundum?

- Corundum is mainly used in advanced grinding materials, watches and precision mechanical bearing materials. A ruby based artificial crystal used as a laser emitting material. Ruby and sapphire are corundum minerals. Except for the starlight effect, only translucent transparent and vivid corundum can be used as gems. The red is called ruby, while the other tones of corundum are commercially referred to as sapphires.

- Q:What kind of refractory material will be used in the glass kiln?

- High temperature & glass corrosion performance of the brick is slightly lower than that of chromium oxide, also by isostatic pressing forming method, its technical indicators ZrO2>65%, <2.0% porosity, volume density of about 4.25g/cm3, the temperature in E glass is higher than 1370 DEG C have erosion. Used in the E glass melting pool unit kiln glass temperature slightly lower at the end of the transition path, forming the bottom of the pool and forming path path flow tank and bushing support brick etc.. In addition, the dense zirconia brick is used as the backing brick of the dense chrome brick.

- Q:What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q:What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q:Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q:What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- The expansion curves of fused cast AZS brick at 1000 DEG C near a crystal anomaly, its internal changes of ZrO2 crystal are reversible, with large volume change, therefore, products containing ZrO2, should not be used in the temperature of 1000 DEG C, often have sharp fluctuations in the position. When baking the kiln, the temperature can not be too large at 900~1150 degrees centigrade. Generally, the temperature can not exceed 15 degrees /h, and the temperature should be raised steadily. Some parts to prevent the cold, with other brick protection, to prevent explosion.

- Q:What are the advantages of refractories?

- Special refractories are new inorganic non-metallic materials developed on the basis of traditional ceramics and refractory materials. For example, AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on

- Q:What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

- Q:How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alumina Spinel Refractory Brick with tough texture and high quality of compression resista

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords