Alumina Professional for Electric Arc Furance Tile Ceramic White Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

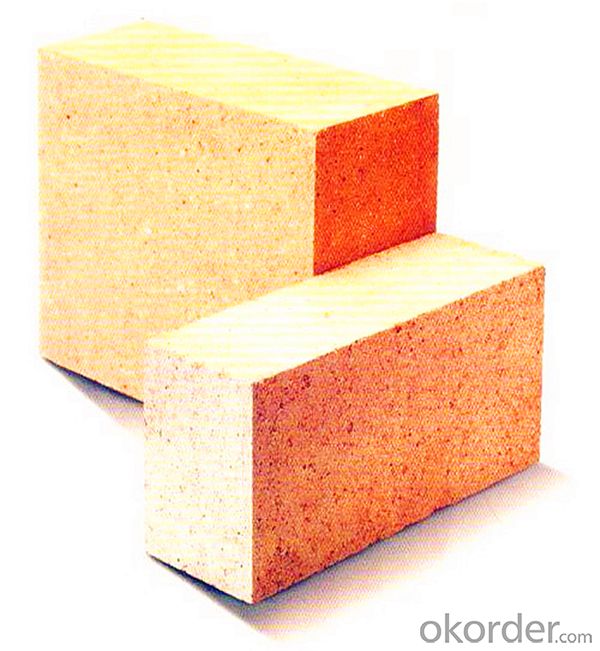

High Alumina Professional for Electric Arc Furance Tile Ceramic White Brick

Product Description

The phosphate bonded high aluminum bricks are with high strength, low bulk density, low thermal, conductivity, high thermal shock resistance and the anti-spalling is good. Widely used in cement kiln,hot blast stove/furnace,EAF(electric arc furnace),coke oven door...

Structure& Advantage

for Our High Aluminum/Alumina Refractory Brick, Fireclay Bricks

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

We Are Suppiler for

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Srs Sorg Refractory Systems GmbH,

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

Major Images

Refractory High Alumium and Fireclay Brick

Specification for High Aluminum Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q:How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

- Q:How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q:What is the high temperature limit of refractory bricks and refractory soil?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q:What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q:Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

- Q:Which thermal shock stability of clay brick and high alumina brick is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q:The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

- Q:What is the heat preservation material used in a laboratory furnace?

- Thermal insulation cotton is a high-purity clay clinker, alumina powder, silica powder, chromium sand and other raw materials in the industrial furnace melting at high temperature, forming fluid. Then, compressed air is used to blow or use the wire throwing machine to turn the yarn into a fiber shape. After the cotton collector is collected, the cotton is formed into a heat preservation cotton.The high alumina brick is usually made of high alumina clinker with small amount of clay. After grinding, the high alumina brick is poured and shaped in the form of slurry by the way of gas generation or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q:The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q:What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alumina Professional for Electric Arc Furance Tile Ceramic White Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords