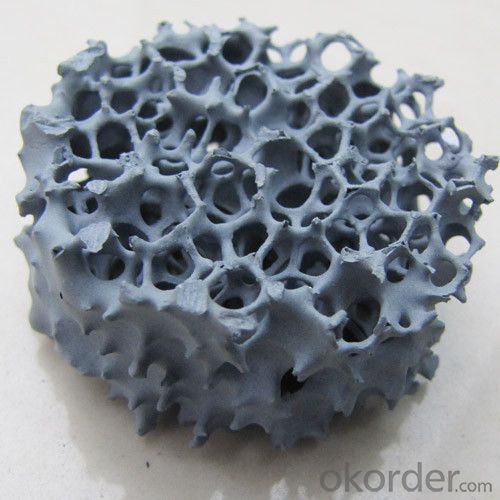

Alumina Circle Ceramic Foam Filter Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Foam Filters

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions slag and dross from the molten metal stream.

Typical Applications of Ceramic Foam Filters

Grey iron casting

ductile iron casting

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q:What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Superfine glass wool insulation rockwool, steam pipe rubber board, aluminum silicate, calcium silicate products, such as polyurethane insulation form, in the application, to see the price, there are commonly used rock wool and polyurethane, rubber board, the price is relatively low, the thickness of rock wool 65, is the most thin.

- Q:Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- The two are thermal insulation materials. Calcium silicate board strength, cheap, but the use of temperature is not high, the highest 1000 degrees.

- Q:What is the maximum temperature at which the glass is cured?

- Glass is softened at a temperature of 600 degrees. When making glass, but ordinary alcohol lamp is enough to soften it. Glass is not crystal. The softening point of lead glass is 500 degrees. The main component of ordinary glass is CaO: Na2O: 6SiO2, which can be softened by fire. In addition to the ordinary glass, glass wire, alcohol burner 1000 degree glass has no definite melting point and freezing point, in softening products can be made into any shape, so there is no fixed melting point, clarification, fluoride special glass based raw materials, slightly higher than 1200 DEG C melting, but the softening point, as well as borate, limestone, mixed melt in glass kiln.

- Q:Calcium silicate board white ICI belongs to wood surface paint?

- No, it isn't。Calcium silicate board material properties should be comparable with cement products, usually referred to as cement board is actually calcium silicate board.

- Q:The ceiling of calcium silicate board and mineral wool board which is good

- Mineral wool board ceiling is different than the calcium silicate board ceiling.Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board.

- Q:What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q:Why is calcium silicate board unsuitable for use in home improvement?

- It is not the appropriate material, calcium gypsum board to hemihydrate gypsum and organic silicone oil as the main material, the surface of the organic silicone oil with the installation way friction transportation will fall, a long time will get loss loss, if the poor quality of the organic silicone coating, it is not full proof effect is worse in the course of time, deformation, damp, moldy yes, yellow.

- Q:What is a building energy-saving materials?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q:Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- The market is generally understood, but in fact, Eterpan belongs to Guangzhou eternit limited production of the 100 year history of eternit brand board, because the cement product is Belgium hetet group invention.

- Q:What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alumina Circle Ceramic Foam Filter Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords