Alloy Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process:

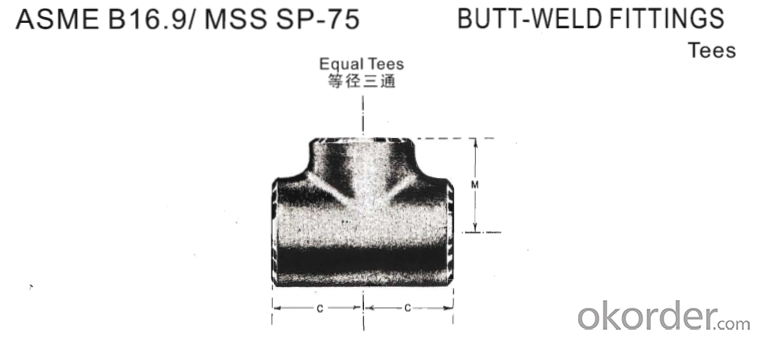

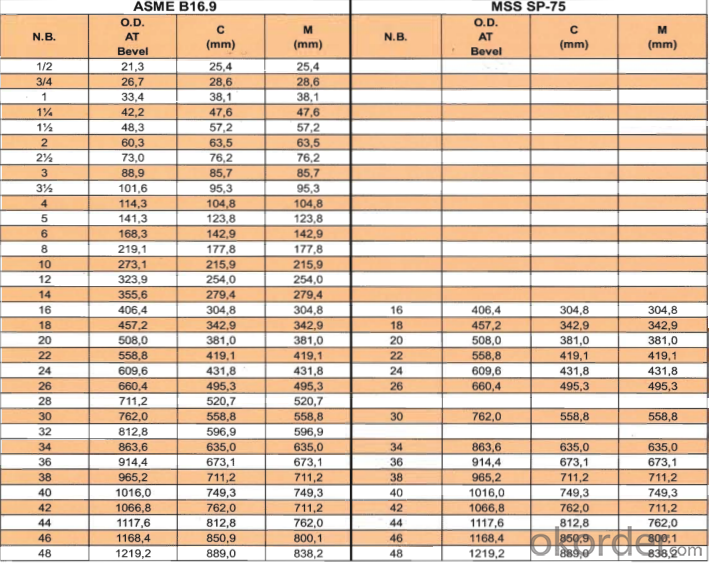

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Equal Tees:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I drive about 1500 miles a month. How many miles before the studs are rendered useless?

- Grounding electrical circuits on the far end of a water pipe will cause this. The current will travel along the pipe to the ground by the water meter, causing that problem. The pin holes are usually on the bottom of a horizontal running pipe. You need to run a ground wire to a ground rod and not use the water pipe. Using a plastic water pipe does don't give you the best ground. Check the water softener to see if it's grounded properly as well.

- Q:What are the types of tubing and pipe couplings?

- According to the number and direction of the connection, there are straight through, right angle, three pass and other types; the connection with the body has threaded connection, flange connection and so on. In addition, there are some special purpose pipe couplings.

- Q:Started at about 2am, the smoke alarm would go off for about 5 seconds, just to wake everyone up. Now, it went off again, same deal, about 5 seconds. I checked the furnace, it was off since midnight last night. I am not experiencing any signs or symptoms of CO poisoning. I check on my dog every 30 minutes or so, he is alert and have perfect coordination. What does it mean, usually the alarm last a lot longer when we bake. All my smoke detectors are linked together, the house was built in 2004.

- probably yes,depending on the sensitivity and type.The majority measure particles in the air.When the air is so thick that an ionization detector starts to choke,then the alarm goes off.Others use a beam of light and a photocell.

- Q:You know the inexpensive, 9 volt battery operated smoke detectors. Should they be replaced on a regular basis? When I push the test button the alarm does sound, but should you still replace them every once in a while?

- make the threads and drill the stainless the size as needed to accept the copper pipe the fittings are not necessary if you do that you may have to braze the copper elbow to mate an elbow or some type of fitting to accommodate the column .. instead of buying all that brazing equipment find a welder that will do those short jobs take you fittings to the welder [[ it costs less for you to go to his shop ]] . enjoy the spirits [[ you will have to give it away as the sale of the moon-shine is against the laws and ATF will not like you .

- Q:What is pressing type pipe joint

- If necessary, I will send you the connector type and specifications

- Q:Okay, I am running Microsoft Windows 2000 Professional NT..every two weeks, it asks me to change the password to get into my computer. Yesterday, I changed it. It has ALWAYS asked me to verify the password, yesterday it did not. Now the password I thought I typed in will not allow me access to enter the machine. I have tried all the suggestions I received to my previous question (thank you all), and now I am stuck on the User name/ old/ new/ confirm screen.when I type any passwords, it tells me that the old password is not correct. The machine belonged to someone before me, and I have never had this problem before. I do not know how to contact the previous owner.so, can I fix this problem, or has my PC become a very expensive paperweight?

- The Fireman's Union has said that small fires turn into big ones very quickly. I can't wait (unless it's my house that is) to see fire engines trundling along at 30 mph in built up areas, with no sirens etc. This is the classic example of the law of unintended consequences as imposed by idiots. I have never heard of a fire engine causing an accident, have you?

- Q:The pipe connections have different diameters. Reducing diameter, and what kind of, and their specific is how to distinguish, I'm a novice, seek expert advice

- If there is no change in diameter: different diameter (that is, variable diameter) joints and the same diameter joints

- Q:Our wired smoke detector near our kitchen never goes off. We've nearly filled the house with smoke (burnt something in the oven) and it won't go off. It has power and it beeps when I press the 'test' button. Any ideas?

- Precious declaration reads Once I jumped thru hoops of fire High and far as you required I was blind but now I see

- Q:I have dining room chairs that have a resin like wood. any tips on how to strip and re-stain it? we got this dining room set and realized after we got it home that there was this resin like wood on the back of the chairs and on the columns of the table. We did notice that it is easy to strip off, but we are not sure on how to re-stain it. We did try to re-stain on a spot that is hard to see, but the stain seems to wipe off when it is dried.

- There is a party in my pants now, thank you very much

- Q:Basically when my alarm goes off, I wake up in a haze, but am not aware enough to know I have to actually GET UP and go to work.Anyone have any tricks for actually getting up when the alarm goes off?

- Synthetic resins are materials with similar properties to natural resins—viscous liquids capable of hardening. They are typically manufactured by esterification or soaping of organic compounds. The classic variety is epoxy resin, manufactured through polymerization-polyaddition or polycondensation reactions, used as a thermoset polymer for adhesives and composites. Epoxy resin is two times stronger than concrete, seamless and waterproof. As such it has been mainly in use for industrial flooring purposes since the 1960s. Since 2000, however, epoxy and polyurethane resins are used in interiors as well, mainly in Western Europe. One more category, which constitutes 75% of resins used, is unsaturated polyester resin. Ion exchange resin is another important class with application in water purification and catalysis of organic reactions. See also AT-10 Resin, melamine resin. Another synthetic polymer is also sometimes called by the same suffix, acetal resin. By contrast with the other synthetics, however, it has a simple chain structure with the repeat unit of form -[CH2O]-.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords