Alloy Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Eccentric Reducers

Features standards and products of our Butt-Welding Eccentric Reducers:

Features of Butt-Welding Eccentric Reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

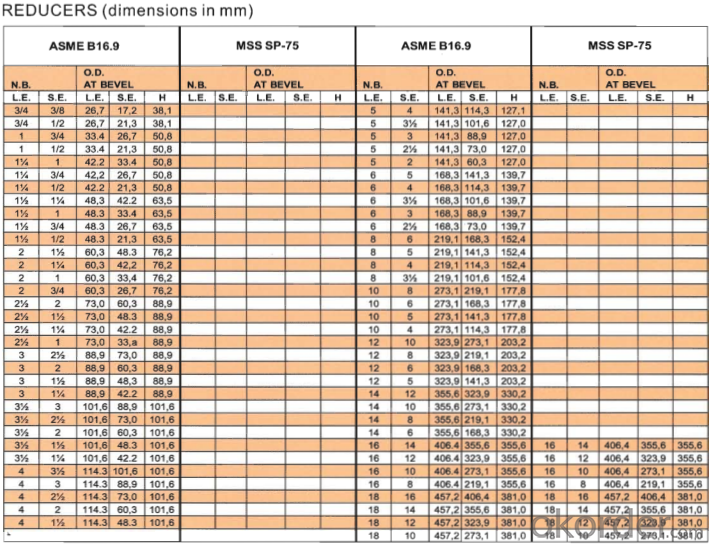

Standards of Butt-Welding Eccentric Reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Eccentric Reducers:

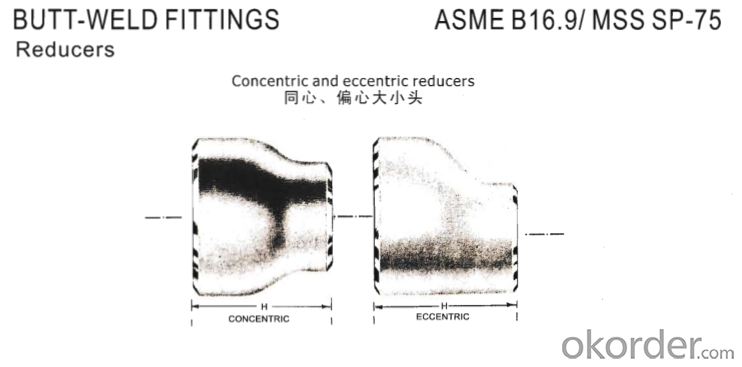

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Eccentric Reducers:

Packing of Butt-Welding Eccentric Reducers:

FAQ of Butt-Welding Eccentric Reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Ok it's supposed to be in the 1st 7 chapters..When Mrs. Maude's house chatches on fire who places the blanket around Scout While she is freezing in the night cold air? I don't remember reading that part can someone please help me! The plus side is its multiple choice: Miss Stephanie Boo Radley Dill Jem

- I would strongly suggest you look up the landlord/condo contract and find out legally what is supposed to be happening here and specifically what the laws are. It's very possible, for insurance reasons, that you could be incorrect. This is not so much an etiquette problem; not now anyway, it could have been before the battle of wills, but now I'd say you need legal help, and if you do not find the specific laws and contracts about this, I think you should seek professional counsel. Do you really want to spend all those lawyer's fees? or could you just go get a new detector or battery at the store and spare yourself a lot of hassle and expense?

- Q:The air conditioner outdoor unit tube joint frost even frozen, then the cooling effect is not very good, let people to put the tube for tube, it is flat, then wash the indoor and outdoor unit for good, but after the tube joint is still the same, even frost freezing, refrigeration effect is very poor, cold still cold, but the results are poor, not very cool. Today, I called the master again. He checked and said there was no air leak, then all the gas was drained and the snow was renewed. Later, that tube interface still frosted, I do not want to call the master, and too much water, so many times can not do.I have always stressed and master is not completely open tube valve is not so cold medium to plugging in there, he has not said, I just want to do you need to twist the valve, how to operate, I just want to look at the valve is not open to the maximum torque.

- Find the right size of the six angle wrench, facing the cut-off valve, counterclockwise turn on the valve, clockwise turn off the valve.

- Q:Can I have your opinion on:?

- Wear a helmet, you need it for safety anyways. Wear a medical mask (like the one they use in hospitals). It will protect insects from getting in your nose and mouth as well as protect you from smog if you are riding on the street. I am not sure what you can do about the ears but hopefully the helmet will help a little. I wear glasses so I would recommend sports glasses if possible.

- Q:This only happens at night, if we have the air conditoner on, after a few hours, our smoke alarm will start beeping in five minute intervals. We have four of them in the apartment and only one of them beeps. What could be causing this?

- The missile system uses IR or Laser to lock onto its target and then notifies the pilot that it is locked. Once locked, the pilot can deploy the missile. On the new F-22 he can lock on multiple targets at once and choose his targets. Once the missile is launched, it has its own onboard control and targeting systems to find the target and the pilot is free to move on to his next target.

- Q:Just wondering how others cope with giving birth while your spouse is deployed.. How did your baby act when they met daddy?How did your spouse take it? Did he seem to love baby anymore/less?Any advise to give a military mommy?

- Most brake lines are 3/16, most foreign fittings are 10mm x 1.25 pitch. You will need to match them up and reorder if daewoo uses something different.

- Q:My husband and I are trying to figure out how to save money on all our bills: electric, home gas, water, and grocery. Grocery is kind of obvious For electric, we obviously turn out all lights when not in use and we also let our dishes air dry. For home gas, we wash all our clothes in cold water and turned the heat from 67 to 60 degrees. We have re-sealed the doors and windows. For water, we only wash dishes in dishwasher and do laundry when it is full. No small loadsAnything you can add to this?

- It was a pretty descent list but as I read at the bottom you started to get a little crazy, why can't they watch tv on weekends or change the channel when they want to watch something else? Why must they be positive? So you are now controlling how they think too? I especially don't agree with you saying that all there grades must be 85 or above, what if they have a learning disability? Or what if they just simply can't reach that goal? Some courses are quite tough you know. I'm hoping this rule only applies to elementary and middle school, you can't expect them to reach 85 or higher in like an advanced physics class

- Q:it's around 45 degrees f at my house, I'm molding a fiberglass paddle.I'm using this stinky polyester resin to wet-out. On the back it says if it's 70-80 degrees use 12 drops of hardener per fl oz, but it's only 45 degrees and I still used 12 drops, will it still work just work slower?

- It was a popular style during the late 70's, then it became trendy again during the early 90's. At present that style is not mainstream or trendy, but, since it was popularized by the punk, I suppose that it might still be popular among the neo-punk, perhaps the EMO's, etc.

- Q:Is it used in Thai or Balanese cooking and if so, how please?

- Darcy's Formula is the general equation for flow of fluids. I was going to list it here, but the notation would be too difficult to express in this format. Find a copy of the book Flow of Fluids Through Valves, Fittings, and Pipe, Technical paper No. 410 by Crane Valves North America

- Q:It's easy to leak if you change the coil several times at the joint. Can I stop it with glue? Solution, please,,

- Glue can not be blocked, mechanical strength is not enough, the use of leakage will occur during the process

- Q:Would I still need to be concerned about carbon monoxide build up if I converted to a heat pump system for my home. I have no appliances that use gas. Could I then get rid of my carbon monoxide detector?

- Ken is right about the stress cracks, I've seen it first hand. I use both, just a couple wraps/layers and then TFE paste with teflon. Hope this helps, and good luck.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products