Alloy Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

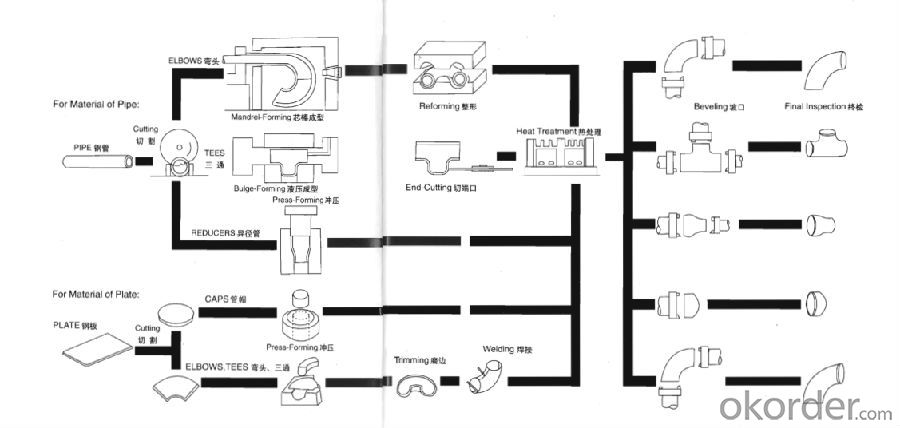

Manufacturing method and process:

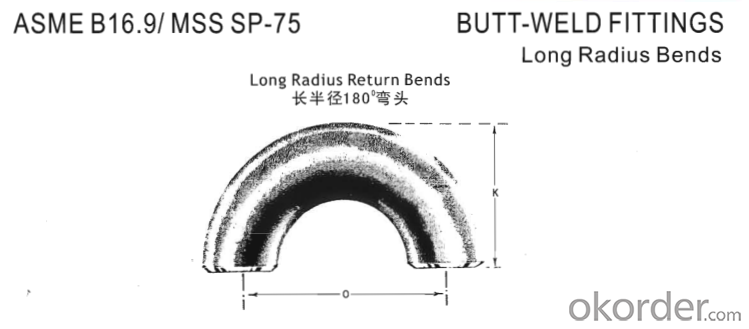

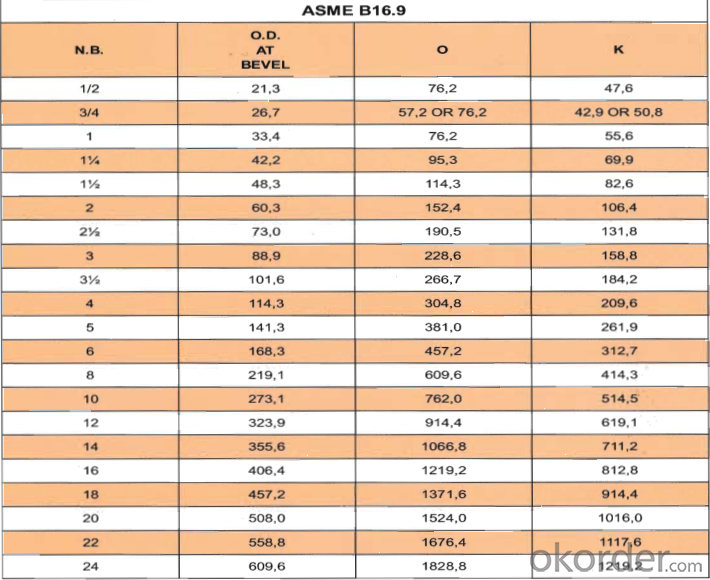

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

180° Long radius bends:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Ok im 12 and my parents are obssesed about safety is there cheap pads (under $60 for set) that can protect you? i dont want to look stupid when playing

- Though the metric system would most likley be easier, a change is no longer realistic. Changing to the metric system will create an extended period of chaos and confusion, a period where we must adjust to the new ways. Besides, there is no major crisis over our current system; It has proven itself, as it has lasted over a century without significant problems. I think these are part of the reasons why many people do not want to make the change.

- Q:I'm interested to know about the General Alarm signals used in sea vessels.They seem to vary greatly from ship to ship depending on the country of origin. The only one that seems to be consistent is the signal used to indicate abandon ship, which is 7 short blasts on the alarm, followed by 1 long blast.Having never heard a general alarm before, what is the duration of a short or long blast?Also, what other signals are commonly used? And are they specific to any country?

- A few nights ago, my mom made some soup like she does everyday. I asked her what it was. She said tomatoes and potatoes soup. I asked her where the potatoes were. She said downstairs (in the box downstairs, we put potatoes, melons, ect.) We all started cracking up.

- Q:Please do not suggest Powder, as I will disregard your answer. I will be purchasing one of these three, so if you can please suggest what one you would feel safest with in your home. Thankyou :D x x

- If you are looking nice ideas for woodworking i can suggest you to check here ( woodworkingplans.kyma ) It's perfect if you are just starting out or if you're a seasoned carpenter. you will like it for sure! It has almost 20.000 woodworking plans and you have a CAD/DWG software to view and edit the plans. You have step-by-step instructions with photos and high quality blueprints and schematics. If you are a beginner this is the easiest way to start your woodworking projects, and if you already have experience you can anyway find a lot of interesting ideas!

- Q:I've a dishwashing job at a restaurant, I don't like to wear those annoying rubber gloves that make my hands sweat. Is it really necessary to wear gloves?

- Within the AHU ther are whats called Dampers a device that is designed to stop the spread of fire normally on the air intake side of the ahu as opposed to the extract side of the system. The BMS is where the system programming is and there are many variations of different logics and situations. Simply you will have a smoke detector of some kind in the AHU, and when smoke is detected it sends a signal to the BMS and closes the Damper and / or the Air intake Fan. Probebly from the design of the system smoke detectors are placed in the higher risk places of the system. Hope this helps, I work on these systems all the time. Neil

- Q:Do you guys think this trio is enough to beat The Shield?

- Buy a properly designed broiler pan. Believe it or not, virtually ALL broiling smoke comes from drippings that puddle on that ill-conceived perforated sheet metal rack. Goggle the best broiler pan ever created and you will find the answer to ALL your broiling problems.

- Q:I straighten it nearly everyday, and dye it. And it's starting to feel like straw, I use moisture conditioner and shampoo, by Aussie, but it isn't doing anything. What do you use to keep your hair hydrated? Something other than, don't dye it, or don't straighten it.thanks [:x

- Paul make sure fitting is dry inside and your using the right flux.A rose bud will work but could burn the fittings if your not careful.Mapp should be plenty of heat for that size.I use propane on 1 all the time.They willnot solder if there wet inside.

- Q:a good cheap rod to use with my team daiwa megaforce plus with twitching bar???

- For most locations in the states you will use the line sizing tables in NFPA 54, the Fuel Gas Code, if you are in Canada as your name might suggest, you will want to check with the local authority having jurisdiction over your installation. The line sizing tables for gas are all basically the same, but some local jurisdictions use slight variations of the nationally recognized standards. You want to be careful using online tables; some tables are for liquid lines that are completely different than vapor service lines. Any tables you see that give flow reduction rates for various pipe fittings are for liquid service. Give the inspector a call and just inquire about what tables and standards are used in your area. Because it’s a school your installation may also require schedule 80 pipe, which will need to be color coded and labeled with flow direction arrows as well. It’s worth doing your homework before you start a job like you have there, because you don’t want to have to go back and re-do things later. Probably not the answer you’re looking for, but I hope it helps.

- Q:Can the copper tube use a clip on pipe joint?

- Clamping sleeve type pipe joint for copper pipe connection.Copper pipe connections are commonly used:

- Q:I was watching Raw tonight and the distraction job that Jericho provided for the Shield seemed a little obvious. I've seen heel turns and they're usually preceded by some mis-fortunate miscommunication that costs the face in some way. Perhaps this is a way to start the feud between Jericho and Ryback? BQ: They're promoting a new wrestler Fandango. I don't know about you, but I think of the movie site when I see it. Seems as though this new gimmick is going to be a littleweak. Do you agree or disagree?

- Sweatsolder with a touch. Contact a plummer.

- Q:Many of the shareholders dislike with current coop board member. They (current board) know that they will lose in the coming election, so they decided to count votes in a different room, away from shareholders' view. I mean this is stupid , even kids know how to cheat in this case. ANYONE can help us? We already have ppl who r willing to replace current board and we sure that we have more than 50 % of shareholders supports the new board. However, nothing mattersIf they are going to cheat in the counting process..This is sad. I am so disappointed something like this is happening on the United States of Amercia ! Some of u might be thinking hiring a lawyer but we think of it, too. We don't think hiring a lawyer would work since current board is still in charge, they can make the rules as long as they are still in chargethis is stupid..

- Yes, if you leave and stay at a hotel she has to prorate your rent for those days. If you agree to stay then no, nothing to compensate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords