Alloy Connector Finish Painting Suspension Ceiling Grid Type

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

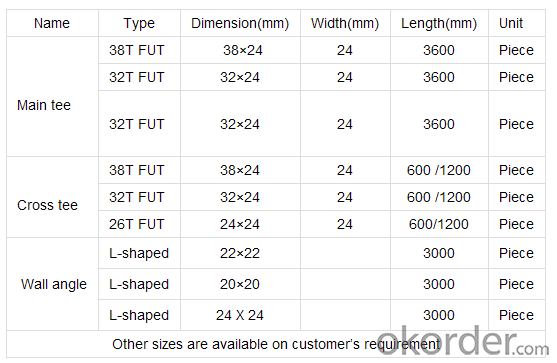

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:Want to do it yourself, read many times others do, I feel almost can get their own. To separate a few small rooms in the big room. 1, is not the first crossed positioning, heaven and earth keel. And then install the heaven and earth keel and vertical keel fixed, and then wear the heart bone, and then the card to the vertical keel and piercing the heart bone fixed. There are several questions, is not the roof and the ground with the heaven and earth keel, vertical and against the walls are used vertical keel? (What are the main accessories? Fixed use of plastic keel or expansion bolts?) 2, the keel all the good, then install the gypsum board? 3, gypsum board surface treatment is the easiest way to what? Office use, as long as the wall on the line, requiring simple and convenient construction. I know there is a direct wallpaper can be posted, do not know that effect is good. There is no master to stay a q number, so that I always consult, very grateful.

- In fact, very simple, I believe you can understand a look. 1. Fixed the use of plastic keel to increase the round head screw (with fixed gasket) on the line. Roof and the ground with the heaven and earth keel, vertical and wall with a vertical keel, no accessories, the interface with a core pulling aluminum rivets or tapping screws. If you want to take a long keel, you can use 20CM long, suitable u-type keel rivets then. (Or open the keel on both sides of the plane rivets) In the crossed positioning, according to the width of the gypsum board, calculate the two plates combined with the size of the middle seam, hammer correction vertical keel vertical. 2. After all the keel is well fixed, fix the gypsum board with the countersunk head screw. 3. Fixed gypsum board, leaving the board interface, use sealing tape tape glue seal, and then painted white or stickers even if you're done.

- Q:Light steel keel can stand people?

- Have a dedicated master keel, you can master.

- Q:the ceiling tile with no keels.(there are keels inside it but you can't see them cuz they're hidden),so how do you call this kind of ceilig tile?

- Sorry Yangyang, but I don't understand the meaning of keels in the ceiling tiles. There is a style of ceiling called a dropped ceiling where a metal grid framework (often white) hangs lower than the original ceiling and square, often white tiles are placed inside the grid. If any wires or repairs need to be done above the dropped ceiling they can just push up on a tile, do the repairs and then drop the tile back into place. It is seen often in office or industrial spaces and occasionally in residential. It is fairly modern. An older style of ceiling treatment know as a tin ceiling tiles are an antique metal patterned and textured tile that are attached directly onto the ceiling. They are found in old and often expensive homes and sometimes restaurants. Although they are an antique (starting in the 1800s) you can still buy plastic or metal ones to add to a home giving it an old style charm. Are either of these what you are looking for?

- Q:Describe your system and architecture. How do you COOL your house? My biggest concern is how to cool a home off the grid.

- the two sites below might give you some ideas.

- Q:I have a manufactured home and trying to finish the basement. I am stuck on how to install a ceiling being there are steel beams instead of wood therefor nothing to attach a grid to. Any ideas or anybody ever done this before?

- you could buy screws with a drill point and a hex head.attach with these to the metal beams drop down enough to clear obstacles support grid with wire hung from screws

- Q:Light steel keel will rust deformation

- There are good quality there are poor, in fact, there are many are so iron to buy the time to buy can not buy cheap

- Q:I'm getting a new room in my house, and I really want to do a mosaic on the ceiling. I love everything artistic so I'd want to do it myself, and I know it's going to take a long time to do a room that's 18 ft by 22 ft, but I really want to. I've actually never done mosaics before and I'm aware that they are difficult to do and that this is a monumental project for someone who has never even done a mosaic before. But I wanted to know the easiest possible way to go about it (because the idea of standing on a ladder the entire time does not appeal to me whatsoever)? Like, could I do the mosaic on another surface and then attach it to my ceiling? or I don't know, please help me.

- Monumental doesn't even came close. To make it realistic you will need to do it on the ceiling, otherwise it will look like patchwork. First thing is to design on paper what you want it to look like. Then transfer design to grid paper. No stepladder. Buy a scaffold that is big enough and high enough to lie on. Transfer your design to the ceiling. You can make stencils for this, and use multiple chalk lines to keep everything straight. Before you start, practice on a plywood board. When you buy your materials, make sure you tell the salesman you are doing a ceiling so you get the right cement or mastic. It took Michelangelo 7 years to do the Sistine Chapel, and he used paint. Good Luck!

- Q:What is light steel keel structure

- This kind of house can be preserved in the earthquake, but very few such a house, because the high cost of the city's temperature and other conditions have a certain impact in OKorder where there is not clear, but there are some in Dalian, Approximately 15000RMB / flat.

- Q:Light steel keel wall hidden acceptance of what is the hidden content? (Not a ceiling)

- 1. The variety, specification, performance and moisture content of the keel, fittings, wall panels, filling materials and caulking materials used in the skeleton walls shall meet the design requirements. There are sound insulation, heat insulation, fire retardant, moisture and other special requirements of the project, the material should have the appropriate performance level of the test report. 2 skeleton wall works Border keel must be firmly connected with the base structure, and should be flat, vertical, position is correct. 3 skeleton in the keel spacing and structure of the connection method should meet the design requirements, the skeleton of the equipment pipeline installation, doors and windows openings and other parts to strengthen the keel should be installed firmly, the correct position, fill the material should be set to meet the design requirements. 4 wood keel and wood wall panel fire and corrosion treatment must meet the design requirements. 5 skeleton wall wall panels should be installed firmly, no delamination, warping, cracks and defects. 6 seam joints used in the joints of the wall method should meet the design requirements. 7 skeleton wall surface should be smooth, consistent color, clean, no cracks, seams should be uniform, straight. 8 skeleton on the wall of the holes, grooves, boxes should be the right position, sets of anastomosis, neat edges. 9 skeleton wall filled with the material should be dry, fill should be dense, uniform, no fall.

- Q:Gypsum board light steel keel cut off how much money 1 square

- Skeleton 20 or so, gypsum board 12 thick side of the double-sided dragon card 30 or so, labor costs ranging from OKorder and around 35, caulking and 5, nail river 2, tools and 3 fast, 90 or so, plus noise Material plus artificial 20 or so, 110

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Connector Finish Painting Suspension Ceiling Grid Type

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords