All Kinds of Colorful Bopp Waterproof Acrylic Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product description

| Material: | BOPP | Use: | Carton Sealing | Adhesive Side: | Single Sided |

| Adhesive: | Acrylic | Adhesive Type: | Pressure Sensitive, Water Activated | Feature: | Waterproof |

| Design Printing: | Offer Printing | Place of Origin: | Beijing, China (Mainland) | MOQ | 1800 rolls |

2.Packaging & Delivery

Packaging Details:

1) individually wrapped,

2)6rolls/ Tower shrink/ Flat_pack,

3)about 36~100rolls/cartonDelivery Detail:

within 15 days after comfirming the deposit and packaging detail

3.Product show

4.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

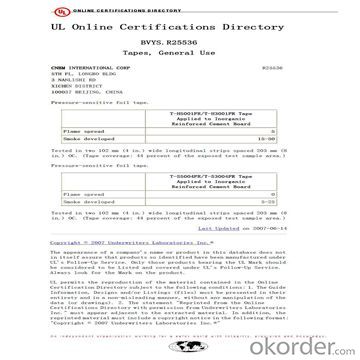

5.Our certification

6.FAQ:

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

- Q:Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q:Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is safe to use on stainless steel. Packaging tape is typically made from materials that are not corrosive and will not damage the surface of stainless steel. However, it is always a good idea to test the tape on a small, inconspicuous area of the stainless steel before applying it to the entire surface, especially if the tape will be left on for an extended period of time. Additionally, removing the tape gently and slowly can help prevent any potential damage or residue on the stainless steel.

- Q:Can packaging tape be used for sealing plastic storage baskets?

- Packaging tape possesses the ability to seal plastic storage baskets. Its strength and adhesive properties render it suitable for securing and sealing diverse materials, encompassing plastic. By implementing packaging tape, one can proficiently seal the openings or seams of plastic storage baskets, thereby ensuring the safeguarding and preservation of the contents. Nevertheless, it is imperative to acknowledge that the seal's durability and efficiency may hinge upon the quality and resilience of the particular packaging tape employed. Furthermore, it is advisable to cleanse and dry the surface of the plastic storage baskets before applying the tape to guarantee adequate adhesion.

- Q:What is the difference between acrylic and hot melt adhesive for packaging tape?

- Acrylic and hot melt adhesives are two common types of adhesives used for packaging tape, and they have some key differences. One major difference is the bonding strength. Hot melt adhesive is known for its excellent bonding strength, making it suitable for heavy-duty applications. It creates a strong and durable bond that can withstand rough handling and varying temperatures. On the other hand, acrylic adhesive typically offers a lower bonding strength compared to hot melt adhesive. While it is still suitable for most general packaging needs, it may not be as ideal for heavy or bulky items. Another difference lies in the application process. Hot melt adhesive is applied in a molten state and solidifies upon cooling. It is typically dispensed using a hot melt glue gun or a hot melt applicator. The quick setting time of hot melt adhesive allows for fast packaging operations, making it popular in high-volume settings. In contrast, acrylic adhesive is applied in a liquid form and requires some time to cure and form a strong bond. It can be applied using a hand dispenser or a tape gun, and it usually requires some pressure for optimal adhesion. Additionally, hot melt adhesive offers good adhesion to a wide range of surfaces, including cardboard, plastics, and metals. It is highly versatile and can be used for various packaging materials. Acrylic adhesive also adheres well to different surfaces, but it may not have the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is another factor to consider. Hot melt adhesive performs well in both high and low temperatures, maintaining its bonding strength. It can withstand freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In summary, the main differences between acrylic and hot melt adhesives for packaging tape lie in bonding strength, application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, fast setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on the specific packaging needs, materials, and environmental conditions.

- Q:How do I store packaging tape?

- For optimal storage of packaging tape, it is recommended to place it in a cool and dry location, avoiding direct exposure to sunlight. This will maintain the tape's adhesive qualities and prevent it from becoming fragile or losing its stickiness. An ideal option for this purpose would be a plastic storage bin or a cool, dry drawer. Additionally, it is advisable to either keep the tape in its original packaging or employ a tape dispenser to safeguard it against dust and other impurities. By adhering to these storage instructions, you can guarantee that your packaging tape remains in excellent condition and readily available for whenever it is required.

- Q:What's the tape for sealing tape?

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q:How does packaging tape perform on rubber surfaces?

- Packaging tape performs relatively well on rubber surfaces. The adhesive on packaging tape is designed to adhere to a variety of materials, including rubber. When properly applied, packaging tape provides a strong bond to rubber surfaces, effectively securing packages or materials together. However, it is important to note that the effectiveness of packaging tape on rubber surfaces may vary depending on the specific type of rubber and the condition of the surface. In some cases, the tape may not adhere as strongly to certain types of rubber, especially if the surface is rough or dirty. It is always recommended to clean and dry the rubber surface before applying packaging tape for optimal adhesion. Additionally, extreme temperatures and moisture may affect the performance of packaging tape on rubber surfaces, so it is advised to store and use the tape within the recommended temperature range and avoid exposing it to excessive moisture. Overall, packaging tape can provide a reliable and secure bond on most rubber surfaces, making it a suitable choice for packaging and securing materials.

- Q:Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Yes, packaging tape can be used for sealing packages with fragile artwork or sculptures. However, it is important to choose the right type of packaging tape to ensure the protection of the artwork. Generally, it is recommended to use a high-quality, heavy-duty packaging tape that is specifically designed for shipping and handling delicate or fragile items. These tapes are often reinforced with fibers or have extra adhesive strength to provide a secure seal and prevent damage during transportation. Additionally, it is advisable to use proper cushioning materials such as bubble wrap or foam padding to protect the artwork inside the package.

- Q:Can packaging tape be used for sealing construction or building materials?

- Indeed, packaging tape possesses the capability to seal construction or building materials. Although it lacks the endurance and strength found in specialized construction tapes, packaging tape can serve as a temporary or expedient remedy for sealing materials like cardboard, plastic sheets, or lightweight panels. It is suitable for fastening interim covers, affixing protective layers, or keeping materials secure throughout construction or renovation endeavors. Nevertheless, for extended or demanding applications, it is advisable to opt for tapes explicitly engineered for construction, as they exhibit superior resistance against weather, UV rays, and possess enhanced adhesive properties.

- Q:Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses. Packaging tape is available in a variety of thicknesses to accommodate different needs and requirements. Thicker tapes are typically more durable and are suitable for heavy-duty applications where extra strength and resistance are necessary. On the other hand, thinner tapes are often used for lighter packages or general everyday use. The choice of thickness depends on the weight and size of the package being secured, as well as the level of reinforcement desired.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

All Kinds of Colorful Bopp Waterproof Acrylic Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products