Alkali Resistant Fiberglass Marble Net for Buildings 120gsm ,5mm*5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alkali Resistant Fiberglass Marble Net for Buildings 120gsm ,5mm*5mm

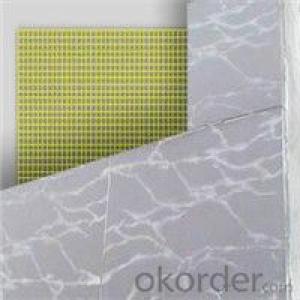

Definition of Fiberglass Marble Net

Marble Mesh is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments.

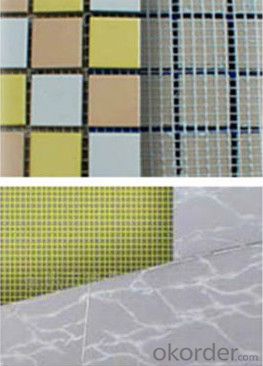

Image of Fiberglass Marble Net

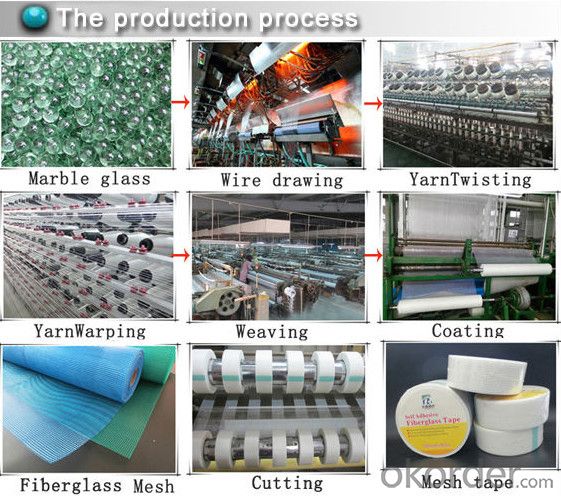

Fiberglass Marble Net Production Process

Application :

Package: Fiberglass Marble Net are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAQ:

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Mesh fabric with plastic glue and latex urinary two relatively better quality products than latex products produced urine glue surface is relatively soft but not broken some customers customized urine gum products according to different uses, our factory can also be customized according to customer requirements of the product corresponds to a

- Q:Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q:What are the fiberglass mesh fabric manufacturers?

- Mesh cloth (heat preservation net)The mesh cloth is based on medium alkali or E-glass fiber woven fabric and is treated with alkali resistant coating. The product has high strength and good alkali resistance, and plays an important structural role in the thermal insulation system, mainly to prevent cracks. Due to its excellent acid, alkali and other chemical substances pedants performance and weft tensile strength is high, can make the wall stress of dispersed insulation system, can avoid the extrusion deformation, external force caused by the collision of the insulation structure, the insulation layer has high impact resistance strength, and easy to construction and quality control, to "soft steel" role in the insulation system.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- Standard: to strengthen the material function and alkali fiberglass mesh cloth to external wall thermal insulation layer, the main role is: to improve the mechanical strength of the surface layer, ensure the continuity of the surface layer resistance, shrinkage pressure and insulation dispersed surface layer stress, avoid stress concentration, surface resistance nature temperature and humidity changes and accidents caused by the impact of the cracking. Therefore, alkali resistant glass fiber mesh fabric plays an important role in the external insulation system, so the selection of good glass fiber mesh fabric is also an important component to ensure the comprehensive quality of the external insulation system. The current national standard technology of exterior insulation (JG149-2003): glass fiber warp and weft resistance tensile strength shall not be less than 750N/50mm, alkali resistant tensile strength retention rate of not less than 50%, more than 130 grams of weight per square meter.

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistance refers to the performance of special glass fiber, while high alkali refers to the composition of glass fiber.Are two completely different concepts.

- Q:Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- Therefore, the first floor insulation system adopts double-layer grid cloth and thickening protection layer, so as to enhance the impact resistance capability of the external insulation system.

- Q:What's the price of fiberglass mesh?

- The elastic coefficient is high, the elongation within the elastic limit is related to the tensile strength of the alkali resistant fiberglass mesh cloth

- Q:Where is fiberglass mesh better?

- Indeed, fiberglass mesh imports are good. Most of the domestic and imported goods still have a certain gap.

- Q:Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q:What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alkali Resistant Fiberglass Marble Net for Buildings 120gsm ,5mm*5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords