Al2O3 86% round kiln calcined bauxite for high-alumina brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

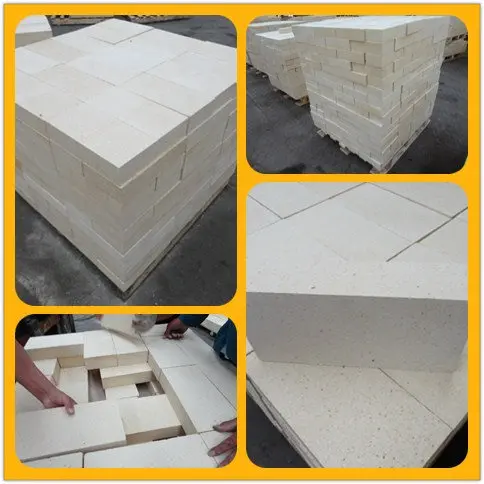

High alumina bricks

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Application of high alumina bricks

High alumina brick is widely used for Widely used in blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln,Tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , Steel smelting furnace and various kiln lining and thermal technical equipment, etc.

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Item | Specification | ||||||

LZ-85 | LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 | 85 | 80 | 75 | 65 | 55 | 48 | |

Apparent density | 23 | 22 | 23 | 23 | 22 | 22 | |

Cold crushing strength | 65 | 55 | 50 | 45 | 40 | 35 | |

RUL | 1600 | 1530 | 1520 | 1500 | 1450 | 1420 | |

PLC | 1500.C*2h | 0.1~-0.4 | |||||

1450.C*2h | 0.1~-0.4 | ||||||

Standards of Type Brick:

| 230mmx114mmx65mm

Product Range: SK32,SK34,SK35,SK36,SK37,SK38

| ||||||

Specail Shape of High Alumina Brick

- Q:Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q:What's the frequently used refractory material?

- Refractory material is generally used in industrial departments like metallurgy, glass, cement, ceramics, machinery, hot working, petrochemical industry, power and national defense. Frequently used common refractory: silica?brick, semi-silica brick, clay brick, high alumina brick, magnesia brick, etc. Frequently used special refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, calcium oxide, chromium hemitrioxide, alumina, magnesium oxide, etc. Frequently used fireclay insulating refractory: diatomite product, asbestos product, insulation?board, etc. Frequently used unshaped refractory: ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, refractory coating, lightweight refractory?castables, etc.

- Q:Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Classified into ordinary and special refractories. The ordinary refractory material is calssified into acid, neutral and alkaline according to the chemical property. Special refractory material is calssified into high temperature oxide according to the composition for , infusible compound and high temperature composite in addition, can be divided into ordinary refractory products according to the fire intensity (1580 ~ 1770 DEG C), high-grade refractory products (1770 ~ 2000 DEG C) and special refractory products (2000 DEG C above). According to the products shape can be divided into bulk (standard brick, special-shaped brick block, special shape (crucible, sagger, pipe, etc), fibrous shape (silicates of aluminum and zirconium oxide and boron carbide matter) and irregular shape (fireclay, refractory castables and incompletely material).

- Q:How to detect the acid resistance of refractory? Is there any standard? Thank you

- What material it is. There are many kinds of refractory materials, and I basically understand all petrochemical refractory.

- Q:What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature.

- Q:Who can tell me about the foundry refractory materials?

- Such as: neutral, alkalic, acidic refractories. Of course, the raw materials of different materials are not the same. Such as: the magnesia-carbon bricks, basic refractory materials: magnesite(electric?smelting, high-purity)+ crystalline flake graphite+ phenolic resin+ additive (aluminate or silicon powder or silicon carbide powder or high-temperature pitch) and so on.

- Q:What is the main material of fireproof wooden door?

- Fireproof wooden door refers to the door whose fire endurance of door frames, skeleton of the door leaf, door panels made of timber or timber work reaches the provisions of "GB50045-95 design of tall buildings for fire protection". Fireproof wooden door contain retardant timner, fireproof expanded perlite and fireproof?panel. Accessories: fireproof glue, fireproof hardware.

- Q:Do you know the refractories?

- Acidic material products: these products to quartz (SiO2) as the first phase, SiO2 is an acid oxide, helped named. Brick is representative of the product acid material; semisilica brick, alkali proof brick, acid brick in SiO2 content of 60% to 80%, is a semi acidic material.

- Q:How to understand qualitative and qualitative refractory materials?

- Such as amorphous refractory castable, referred to as bulk loading, cast material, ramming material, refractory clay etc., utensils and other special products. Amorphous refractory material products, refractory heat insulating bricks and experimental and industrial crucible, spraying materials, such as burning bricks, electric melting brick, turn it into required shape and process heat treatment in where it is used.

- Q:How many refractories are there for boiler above 1200 ℃?

- Ordinary clay brick is for burning layer, red brick for external wall, light clay brick for thermal insulation layer, built by clay refractory mortar. Sindeyuan Refractories.Hope you adopt. Thank you. In fact, there are many manufacturers producing furnace burden. We has been using products of Huaheng, which are anti-erosion, easy to construct and can improve production efficiency, reduce steelmaking cost.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Al2O3 86% round kiln calcined bauxite for high-alumina brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords