AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

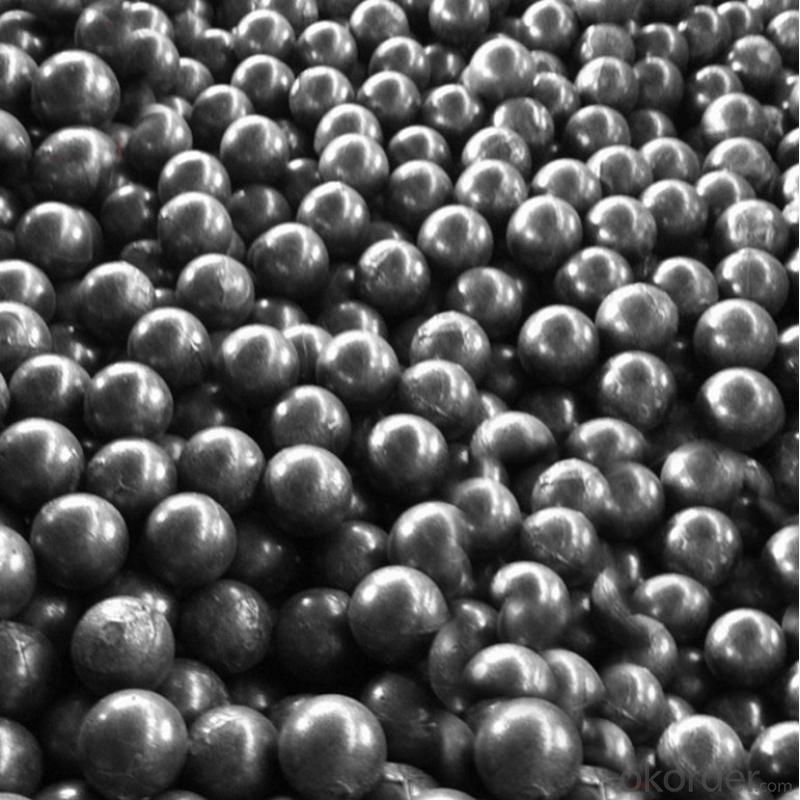

Products Picture

| Product | AISI420 G100 All Sizes Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chorme steel ball .

Strict peocess

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification .

Competitive price: We are a direct steel ball manufacture, lower price is possible

Advanced production flow: With our more than 20 years experience, we have explored compelete production flow, high quality has become an advantage.

- Q:How is steel used in the production of medical devices and equipment?

- Steel is commonly used in the production of medical devices and equipment due to its strength, durability, and resistance to corrosion. It is used to manufacture surgical instruments, orthopedic implants, hospital beds, and various other medical tools. Additionally, stainless steel, a type of steel containing chromium, is often used to ensure sterilization and prevent infections in healthcare settings.

- Q:How do steel products contribute to the infrastructure development of cities and urban areas?

- Steel products contribute to the infrastructure development of cities and urban areas in several ways. Firstly, steel is a versatile and durable material that is used in the construction of buildings, bridges, and roads, providing the necessary strength and stability to withstand heavy loads and harsh weather conditions. Secondly, steel is a key component in the construction of high-rise buildings, allowing for taller and more efficient use of limited urban space. Additionally, steel products such as pipes and beams are crucial in the development of water supply and transportation systems, ensuring the efficient flow of resources and people within cities. Overall, the use of steel products in infrastructure development enhances the safety, efficiency, and sustainability of cities and urban areas.

- Q:What are the different grades of steel?

- There are several different grades of steel, classified based on their composition and properties. Some common grades include mild steel, stainless steel, high-strength low-alloy steel, and tool steel. Each grade is designed for specific applications and offers varying levels of strength, corrosion resistance, hardness, and other desirable characteristics.

- Q:What are the different types of steel sheets and their uses in the aerospace industry?

- There are several types of steel sheets used in the aerospace industry, including stainless steel, titanium, and aluminum alloys. Stainless steel sheets are often used in aircraft structures due to their high strength and resistance to corrosion. Titanium sheets are preferred for their lightweight properties and exceptional strength-to-weight ratio, making them suitable for critical components like landing gear and engine parts. Aluminum alloy sheets are commonly utilized for their low density, excellent formability, and good resistance to fatigue, making them ideal for aircraft skins and panels. Overall, each type of steel sheet has its unique characteristics that cater to specific needs within the aerospace industry.

- Q:How is steel used in the production of electrical transformers?

- Steel is used in the production of electrical transformers primarily for its magnetic properties. It is used to create the core of the transformer, which helps in the efficient transfer of electrical energy by reducing energy losses through magnetic induction.

- Q:How is steel used in the production of elevator systems?

- Steel is a crucial material in the production of elevator systems as it is used for constructing the elevator car, the support structure, and the guide rails, ensuring durability, strength, and safety for the entire system.

- Q:What are the different types of heat treatment processes for steel?

- There are several different types of heat treatment processes for steel, including annealing, normalizing, quenching, tempering, case hardening, and precipitation hardening. Each process has its own specific purpose and effects on the steel's properties.

- Q:What are the different types of steel sheets and their uses in the automotive industry?

- There are various types of steel sheets used in the automotive industry, including hot-rolled, cold-rolled, galvanized, and advanced high-strength steel (AHSS) sheets. Hot-rolled steel sheets are commonly used for structural components due to their high strength and durability. Cold-rolled steel sheets, on the other hand, are preferred for body panels and other parts requiring excellent surface finish and dimensional accuracy. Galvanized steel sheets are coated with a layer of zinc, making them highly resistant to corrosion and ideal for automotive body panels. Lastly, AHSS sheets are specifically designed to provide superior strength while reducing weight, thereby enhancing fuel efficiency and safety in vehicles.

- Q:What are the applications of alloy steel in the energy sector?

- Alloy steel is widely used in the energy sector due to its exceptional strength, durability, and resistance to corrosion. It finds applications in various components such as pipelines, power generation equipment, turbines, and drilling equipment. The high strength-to-weight ratio of alloy steel makes it ideal for constructing structures that can withstand high pressures and temperatures, ensuring reliable and efficient energy production and transmission. Additionally, alloy steel's resistance to corrosion makes it suitable for use in harsh environments, such as offshore oil and gas platforms, where exposure to seawater and other corrosive substances is common.

- Q:Can steel be recycled?

- Yes, steel can be recycled. In fact, steel is one of the most recycled materials in the world due to its durability and potential for infinite reuse without losing its properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords