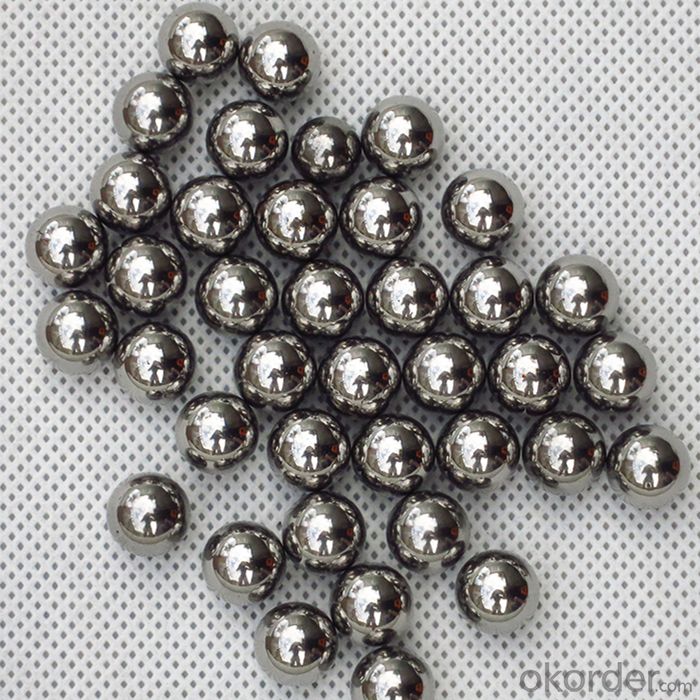

AISI304 Steel Shot 6mm G100 Nail Polish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

The detail of AISI304 stianless steel ball

Here are many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRC25-39

A, Safe Package

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

B,Sample free

If you are interested in our product , we can send you our free sample for you . Please contact us as soon as possible.

| Product | stianless steel ball |

| Material | stianless steel |

| Test | SGS |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

- Q:How are steel sheets used in roofing and cladding systems?

- Steel sheets are commonly used in roofing and cladding systems due to their durability, strength, and resistance to harsh weather conditions. These sheets are installed as a protective layer over the roof or walls of a building, providing a sturdy barrier against external elements such as rain, wind, and sunlight. Steel sheets are easy to install, lightweight, and can be fabricated into various shapes and sizes to meet specific design requirements. Additionally, they offer excellent fire resistance, longevity, and require minimal maintenance, making them a popular choice for roofing and cladding applications.

- Q:What are the different types of steel beams used in building structures?

- There are several different types of steel beams commonly used in building structures, including I-beams, H-beams, and C-beams. These beams vary in shape and size, with I-beams being the most commonly used due to their versatility and strength. H-beams are similar to I-beams but have wider flanges, providing additional support for larger structures. C-beams, also known as channel beams, have a C-shaped cross-section and are often used as support elements in smaller structures or as framing members.

- Q:What are the different types of steel alloys?

- There are several different types of steel alloys, including carbon steel, stainless steel, tool steel, alloy steel, and high-strength low-alloy steel.

- Q:How is steel plate formed into seamless pipes?

- Steel plate is formed into seamless pipes through a process called hot rolling. In this process, a steel plate is heated and then passed through a series of rolling mills to gradually reduce its thickness and shape it into a cylindrical form. The edges of the plate are then welded together to create a seamless pipe.

- Q:How is steel used in the production of defense equipment?

- Steel is used in the production of defense equipment due to its strength, durability, and ability to withstand high temperatures and impact. It is commonly used in the manufacturing of armored vehicles, tanks, submarines, and various weapons, providing the necessary protection and structural integrity required for military applications.

- Q:What are the advantages of using steel in automotive chassis?

- There are several advantages of using steel in automotive chassis. Firstly, steel is highly durable and has a high strength-to-weight ratio, meaning it can provide excellent structural integrity while keeping the overall weight of the vehicle low. This enhances fuel efficiency and improves performance. Additionally, steel offers excellent crash protection as it can absorb and distribute impact forces effectively, thus enhancing the safety of the vehicle occupants. Steel is also readily available and cost-effective, making it a preferred choice for automotive manufacturers.

- Q:How is steel tubing used in heat exchangers?

- Steel tubing is commonly used in heat exchangers due to its excellent thermal conductivity and durability. It is employed to create the primary heat transfer surface within the heat exchanger, allowing efficient transfer of heat from one fluid to another. The steel tubing's high strength and resistance to corrosion ensure the heat exchanger's longevity and reliability, making it a preferred choice in various industrial applications.

- Q:What are the properties of tool steel for cutting applications?

- Tool steel is specifically designed for cutting applications due to its unique properties. It possesses exceptional hardness, wear resistance, toughness, and heat resistance. These properties allow tool steel to withstand high temperatures, maintain its sharpness, and resist deformation or chipping during cutting operations. Additionally, tool steel exhibits good edge retention and can be easily sharpened, making it an ideal choice for tools used in cutting applications.

- Q:What are the different types of steel coatings for corrosion prevention?

- Some common types of steel coatings for corrosion prevention include zinc coatings (such as galvanization), epoxy coatings, polyurethane coatings, and ceramic coatings.

- Q:What are the properties of galvanized steel?

- Galvanized steel is a type of steel that has been coated with a layer of zinc to protect it from corrosion. Its main properties include excellent durability, resistance to rust and corrosion, high strength and toughness, and a shiny appearance. Additionally, galvanized steel is cost-effective, easy to work with, and has a long lifespan, making it a popular choice in various industries, such as construction, automotive, and manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI304 Steel Shot 6mm G100 Nail Polish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords