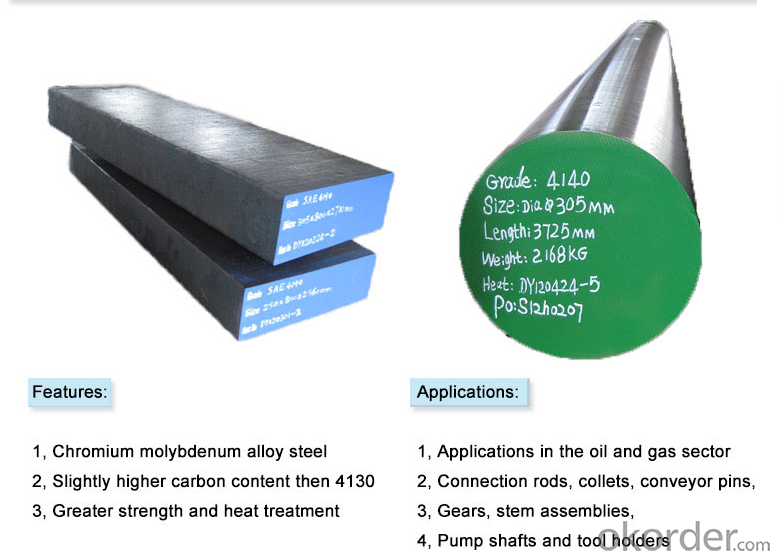

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

AISI 4140 Carbon Alloy Steel Round Bars

Product information:

- High Quanlity

-Various Type and Specification

-Competetive Price

- Perfect Service

-On Time Delivery

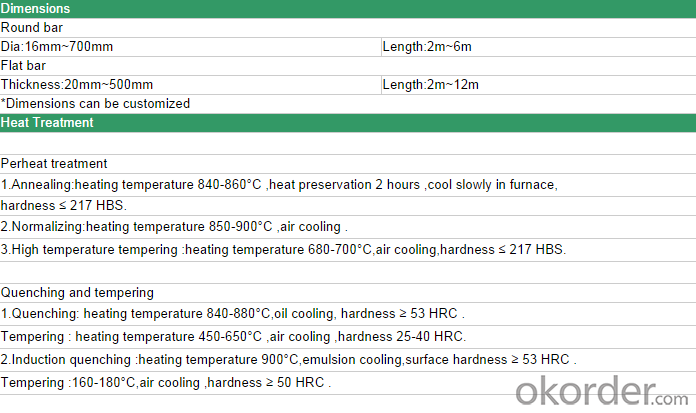

2.Process: EAF + LF + VD + Forged + Heat Treatment (optional)

3.Delivery condition: Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

4.Technical Data: According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

5.Test: ultrasonic test according to SEP 1921-84 3 D/D

6.Material details will be as per agreed technical specifications

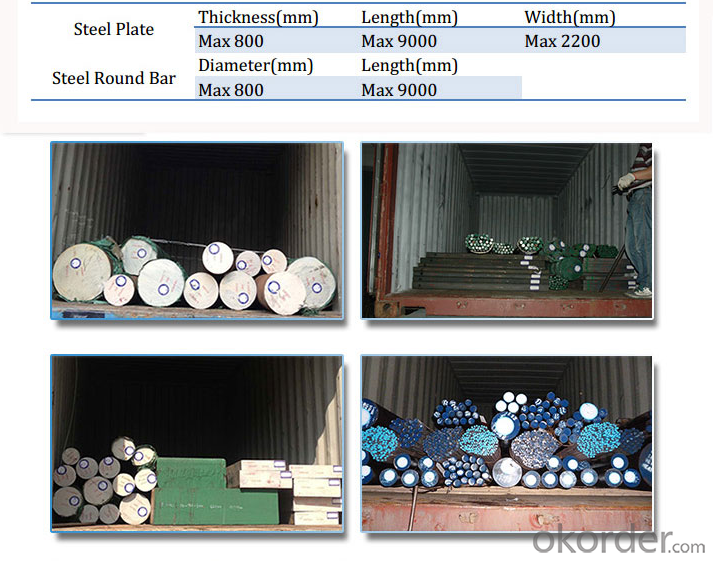

Other product show:

Our workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q:Can special steel be used in cryogenic applications?

- Yes, special steel can be used in cryogenic applications. Special steels, such as stainless steels, are known for their excellent resistance to low temperatures and can maintain their mechanical properties even at extremely cold temperatures. This makes them suitable for use in cryogenic applications where materials need to withstand and perform well in extreme cold environments.

- Q:What are the main factors affecting the heat resistance of special steel?

- The main factors affecting the heat resistance of special steel include its alloy composition, microstructure, and heat treatment. Alloy composition plays a crucial role in determining the heat resistance of special steel. The addition of specific elements such as chromium, nickel, molybdenum, and tungsten can enhance the steel's ability to withstand high temperatures. These alloying elements form stable oxide layers on the surface of the steel, which act as a barrier against oxidation and corrosion at elevated temperatures. The microstructure of special steel also influences its heat resistance. The steel's grain size, distribution of phases, and the presence of precipitates can affect its thermal stability. Fine-grained structures and a homogeneous distribution of phases help improve the steel's resistance to creep, which is the deformation that occurs under prolonged exposure to high temperatures. Additionally, the presence of precipitates, such as carbides or intermetallic compounds, can provide strengthening mechanisms that enhance the steel's resistance to thermal softening. Heat treatment processes, such as quenching and tempering, can significantly impact the heat resistance of special steel. Proper heat treatment can optimize the microstructure and enhance the steel's mechanical properties, including its resistance to thermal degradation. For instance, a well-controlled quenching process can promote the formation of a martensitic structure, which increases the steel's hardness and strength at high temperatures. Other factors that can affect the heat resistance of special steel include the presence of impurities, surface conditions, and environmental factors. Impurities, such as sulfur and phosphorus, can reduce the steel's resistance to high temperatures by promoting the formation of brittle phases or facilitating oxidation. Surface conditions, such as roughness or the presence of cracks, can lead to localized heating and accelerated degradation. Environmental factors, such as the presence of corrosive gases or high humidity, can also influence the steel's heat resistance by promoting oxidation or corrosion processes. In summary, the heat resistance of special steel is influenced by its alloy composition, microstructure, heat treatment, impurities, surface conditions, and environmental factors. Understanding and optimizing these factors are crucial for developing special steel with superior heat resistance for various industrial applications.

- Q:How are tungsten alloys used in the defense industry?

- Tungsten alloys are commonly used in the defense industry due to their exceptional properties such as high density, strength, and resistance to heat and corrosion. These alloys are used in various applications including armor piercing ammunition, kinetic energy penetrators, and armor plating for military vehicles and aircraft. Their ability to withstand extreme conditions and penetrate hardened targets make tungsten alloys vital for enhancing the effectiveness and protection capabilities of defense systems.

- Q:What is the difference between stainless steel and special steel?

- Stainless steel is a type of steel that contains a minimum of 10.5% chromium content, which helps it resist corrosion and staining. On the other hand, special steel refers to a wide range of steel alloys that are specifically designed and manufactured for specific applications or purposes, such as high-strength, heat-resistant, or wear-resistant properties. So, while stainless steel is a specific type of steel with corrosion-resistant properties, special steel encompasses various alloys tailored for specific needs.

- Q:What are the different impact-resistant grades of special steel?

- Impact-resistant grades of special steel refer to steel alloys that are specifically designed to withstand high impact and shock loads without fracturing or deforming. These grades of steel are commonly used in applications where resistance to impact and toughness are crucial, such as in construction, mining, automotive, and defense industries. There are several different impact-resistant grades of special steel available, each with its own unique characteristics and properties. Some of the commonly used impact-resistant grades include: 1. AR400: This grade of steel has a nominal hardness of 400 Brinell (HB) and is known for its exceptional resistance to abrasion and impact. It is often used in applications where high wear resistance is required, such as in bucket liners, crushers, and hoppers. 2. AR500: With a nominal hardness of 500 HB, AR500 steel offers even higher resistance to wear and impact compared to AR400. It is commonly used in applications involving heavy machinery, mining equipment, and armored vehicles. 3. AR600: This grade of steel has a nominal hardness of 600 HB, making it one of the toughest and most impact-resistant steels available. It is often used in applications where extreme wear resistance and durability are essential, such as in chutes, conveyors, and ballistic protection. 4. T-1: T-1 steel is a high-strength, low-alloy (HSLA) steel that offers excellent impact resistance and toughness. It is typically used in applications where high strength and toughness are required, such as in structural components, heavy equipment, and offshore drilling rigs. 5. QT or Quenched and Tempered Steels: These steels are specifically heat-treated to enhance their toughness and impact resistance. They are commonly used in applications that require a combination of high strength, toughness, and impact resistance, such as in gears, shafts, and armor plates. It is important to note that the specific impact resistance of a steel grade depends not only on its composition but also on factors such as heat treatment, fabrication techniques, and design considerations. Therefore, it is crucial to consult with steel manufacturers or experts to determine the most suitable impact-resistant grade for a particular application.

- Q:What are the properties of corrosion-resistant steel?

- Corrosion-resistant steel, also known as stainless steel, possesses several key properties. Firstly, it has a high resistance to corrosion, making it suitable for use in environments with exposure to moisture or corrosive substances. Secondly, it contains a minimum of 10.5% chromium, which forms a protective layer called chromium oxide on the surface, preventing further corrosion. Additionally, it has a strong resistance to staining, which makes it easy to clean and maintain. Moreover, corrosion-resistant steel exhibits excellent strength and durability, making it suitable for a wide range of applications in various industries.

- Q:How does special steel contribute to weight reduction in manufacturing?

- Special steel, engineered specifically for various manufacturing applications, possesses certain characteristics that make it suitable. One major advantage of special steel is its ability to reduce weight in manufacturing processes. Industries that prioritize weight reduction, such as automotive, aerospace, and construction, often utilize special steel. This is because special steel has a high strength-to-weight ratio, meaning it can provide the necessary strength and performance while being lighter compared to other materials. Using special steel allows companies to achieve weight reduction in multiple ways. Firstly, the lightweight nature of special steel enables the production of significantly lighter components and structures compared to conventional materials. This reduction in weight offers several benefits, including improved fuel efficiency in automobiles, increased payload capacity in aircraft, and easier handling and installation in construction projects. Moreover, special steel's high strength-to-weight ratio allows manufacturers to design and produce thinner yet equally strong components. This not only reduces overall weight but also optimizes material usage, leading to cost savings and a more sustainable manufacturing process. Additionally, special steel's unique properties, such as excellent formability and weldability, facilitate the creation of complex and intricate designs that further contribute to weight reduction. This versatility enables the production of lightweight components with intricate shapes and structures, enhancing overall performance and functionality. In conclusion, special steel is crucial in reducing weight during manufacturing processes. Its high strength-to-weight ratio, lightweight nature, excellent formability, and weldability enable the production of lighter components and structures. By utilizing special steel, industries can achieve improved efficiency, performance, and sustainability in their manufacturing operations.

- Q:What is the impact of high temperature on the mechanical properties of special steel?

- High temperatures can significantly affect the mechanical properties of special steel. As the temperature increases, the steel's strength and hardness decrease, leading to reduced load-carrying capacity and increased susceptibility to deformation and failure. High temperature can also cause a decrease in toughness and ductility, making the steel more brittle and prone to fracture. Additionally, the expansion and contraction of the steel due to thermal cycling can induce stress and lead to thermal fatigue, further compromising its mechanical integrity. Therefore, it is crucial to consider the impact of high temperature on the mechanical properties of special steel when designing and operating systems that involve elevated temperatures.

- Q:What are the characteristics of special stainless steel?

- Special stainless steel, also known as superalloys, possess several unique characteristics. Firstly, they exhibit exceptional resistance to corrosion, making them highly durable and long-lasting in harsh environments. Additionally, they have high strength and toughness, allowing them to withstand extreme temperatures and pressures. Special stainless steel also demonstrates excellent heat resistance, making it suitable for applications in high-temperature environments. Furthermore, these alloys often exhibit superior chemical stability, resistance to wear and tear, and excellent mechanical properties, making them highly versatile for various industrial applications.

- Q:How does special steel contribute to the transportation sector?

- Special steel contributes to the transportation sector by providing high-strength and lightweight materials that enhance the performance, efficiency, and safety of vehicles. It is used in various components, such as engine parts, chassis, and suspension systems, to improve fuel economy, reduce emissions, and enhance durability. Additionally, special steel's corrosion resistance properties make it suitable for manufacturing components in harsh environments, such as marine and aerospace applications, further expanding its contribution to the transportation industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords