AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products information

Name | AISI 316L welded/seamless stainless steel pipe |

Standard | GB,JIS,DIN,EN,ASTM A554, A249, A269,A312,A213 and A270 |

Material Grade | 201: Ni 0.8%~1% |

202: Ni 3.5%~4.5% | |

304: Ni 8%, Cr 18% | |

316: Ni 10%, Cr 18% | |

316L: Ni10%~14% | |

310S:Ni19%-22% | |

Outer Diameter | 5-600mm |

Thickness | 0.3-100mm |

Length | 6m or as customers' request |

Tolerance | a) Outer Diameter: +/- 0.2mm |

b) Thickness: +/- 0.02mm | |

c) Length: +/- 5mm | |

Surface | 180G, 240G, 320G Satin / Hairline 400G, 600G Mirror finish,matte |

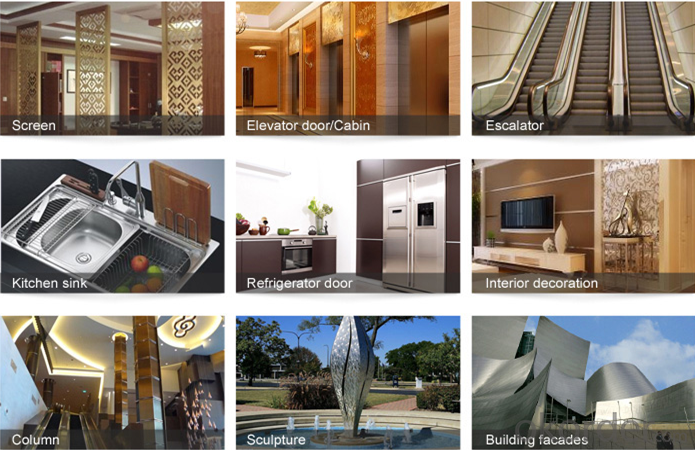

Application | handrail, railing, staircase, weld mesh screen, door, window, balcony, fence, bench, furniture, etc |

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

Picture--aisi 316l stainless steel pipe

Physical properties:

---aisi 316l stainless steel pipe/tube Feature

A) cold-rolled product appearance, good gloss, beautiful;

2) the addition of Mo, corrosion resistance, especially resistance to pitting corrosion;

3) excellent high temperature strength

4) Excellent hardening (after processing weakly magnetic)

5) solid solution state non-magnetic;

6) relative to 304 stainless steel, and higher prices.

Chemical composition

---aisi 316l stainless steel pipe

Stainless Steel tube/pipe grade | |||||||

Grade | Chemical composition | ||||||

C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr | |

201 | 0.15 | 1.00 | 5.5-7.5 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

202 | 0.15 | 1.00 | 7.5-10.0 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

309 | 0.2 | 1.00 | 2.00 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

309S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310 | 0.25 | 1.50 | 2.00 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316Ti | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

2205 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 4.50-6.50 | 22.00-23.00 |

410 | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

430 | 0.12 | 0.12 | 1.00 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

Application

---aisi 316l stainless steel pipe

The main applications include:

1.Petro-Chemical industry Onshore and offshore oil and gas industry

2.Power generation (Thermal and Nuclear)

3.Chemical industry

4.Ship building industry

5.Pulp & paper industry

6.Automotive industry

7.Pharmaceutical industry

8.Food industry

9.Equipment manufacturers (heat exchanger,boiler, condenser,feedwater heater,evaporator

- Q:What is the difference between 321 and 321H stainless steel pipes?

- The carbon content and resulting mechanical properties are what distinguish 321 stainless steel pipes from 321H stainless steel pipes. Both grades are stabilized austenitic stainless steels with titanium as the stabilizing element. However, 321H contains a higher carbon content compared to 321. The higher carbon content in 321H contributes to enhanced strength at high temperatures and resistance to creep. This makes 321H ideal for applications involving elevated temperatures, such as the production of heat exchangers, furnace components, and other high-temperature equipment. On the contrary, 321 stainless steel pipes are commonly utilized in situations where exposure to high temperatures is not necessary. They possess excellent resistance to intergranular corrosion and are frequently employed in the aerospace industry, as well as in the manufacturing of exhaust systems, chemical processing equipment, and other versatile applications. To summarize, the distinction between 321 and 321H stainless steel pipes lies in their carbon content and resulting mechanical properties. 321H is specifically engineered for high-temperature applications, while 321 is suitable for general-purpose applications that do not require exposure to elevated temperatures.

- Q:Can stainless steel pipes be used for oil and gas refineries?

- Yes, stainless steel pipes can be used for oil and gas refineries. Stainless steel offers excellent corrosion resistance, high strength, and durability, making it suitable for handling various corrosive fluids and gases in the refining process. Additionally, stainless steel pipes can withstand high temperatures and pressures, ensuring the safe and efficient transportation of oil and gas in refineries.

- Q:Can stainless steel pipes be used for irrigation systems?

- Indeed, irrigation systems can utilize stainless steel pipes. Stainless steel boasts exceptional corrosion resistance, rendering it a prime selection for water-related purposes. It can endure the demanding conditions inherent in irrigation systems, such as chemical exposure, fertilizers, and fluctuating temperatures. Moreover, stainless steel pipes exhibit durability and possess a lengthy lifespan, guaranteeing the irrigation system's longevity. Furthermore, they deliver superb flow rates and can withstand high-pressure water without experiencing leakage or harm. Consequently, stainless steel pipes represent a dependable and effective choice for irrigation systems.

- Q:How do stainless steel pipes compare to brass pipes?

- Stainless steel pipes are generally more durable, corrosion-resistant, and have higher heat resistance compared to brass pipes. Additionally, stainless steel pipes are often more cost-effective in the long run due to their longevity and low maintenance requirements. Brass pipes, on the other hand, are known for their excellent conductivity and aesthetic appeal. Ultimately, the choice between stainless steel and brass pipes depends on the specific needs and preferences of the application.

- Q:Are stainless steel pipes suitable for heat exchangers?

- Yes, stainless steel pipes are suitable for heat exchangers. Stainless steel is known for its excellent heat resistance properties, making it an ideal choice for applications involving high temperatures. It can withstand extreme heat without deforming or losing its structural integrity. Additionally, stainless steel is highly corrosion-resistant, which is crucial for heat exchangers as they are often exposed to corrosive fluids or environments. The corrosion resistance ensures the longevity and reliability of the heat exchanger, reducing the risk of leaks or failures. Stainless steel pipes also offer excellent thermal conductivity, allowing for efficient heat transfer between the fluids in the exchanger. Overall, stainless steel pipes are widely used in heat exchangers due to their durability, corrosion resistance, and ability to withstand high temperatures.

- Q:Are stainless steel pipes resistant to abrasion?

- Stainless steel pipes possess remarkable resistance to abrasion, thanks to the exceptional characteristics of stainless steel, including its exceptional hardness and strength. Crafted from an alloy that comprises at least 10.5% chromium, stainless steel pipes are endowed with a protective coating on their surface, which efficiently thwarts rust and corrosion. This protective layer further aids in resisting abrasion, rendering stainless steel pipes an outstanding option for situations prone to intense wear and tear. Furthermore, stainless steel pipes exhibit remarkable heat resistance and durability, making them the perfect choice for industries like oil and gas, chemical, and construction.

- Q:Can stainless steel pipes be used for solar thermal systems?

- Yes, stainless steel pipes can be used for solar thermal systems. Stainless steel is highly corrosion resistant and can withstand the high temperatures and pressures typically found in solar thermal systems. It is a reliable and durable choice for transporting the heat transfer fluid in these systems.

- Q:Can stainless steel pipes be used for wastewater treatment systems?

- Yes, stainless steel pipes can be used for wastewater treatment systems. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for pipes in harsh environments such as wastewater treatment plants. These pipes can withstand the corrosive nature of wastewater, including the presence of chemicals and different pH levels. Stainless steel pipes also have a smooth surface, which helps to minimize the accumulation of waste and bacteria, ensuring the efficient flow of wastewater through the system. Additionally, stainless steel is easy to clean and maintain, making it a cost-effective and reliable choice for wastewater treatment systems.

- Q:How much is one ton of stainless steel pipe?

- Basically, each shop is not the same, each place is not the same, you can ask more about the goods than three?

- Q:Can stainless steel pipes be insulated with Teflon?

- Indeed, Teflon can be utilized to insulate stainless steel pipes. Teflon, or polytetrafluoroethylene (PTFE) as it is also referred to, is a highly adaptable substance that is frequently employed due to its nonstick properties and its ability to withstand high temperatures and chemicals. It is an exceptional option for insulating stainless steel pipes since it provides thermal insulation, guards against corrosion, and prevents heat loss or gain. Furthermore, Teflon insulation minimizes condensation or moisture accumulation on the pipe's surface. Moreover, Teflon's low friction coefficient enables smooth fluid flow through the pipes, rendering it appropriate for a wide range of applications in industries like food processing, pharmaceuticals, and chemicals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords