Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

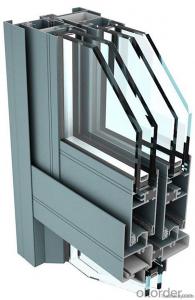

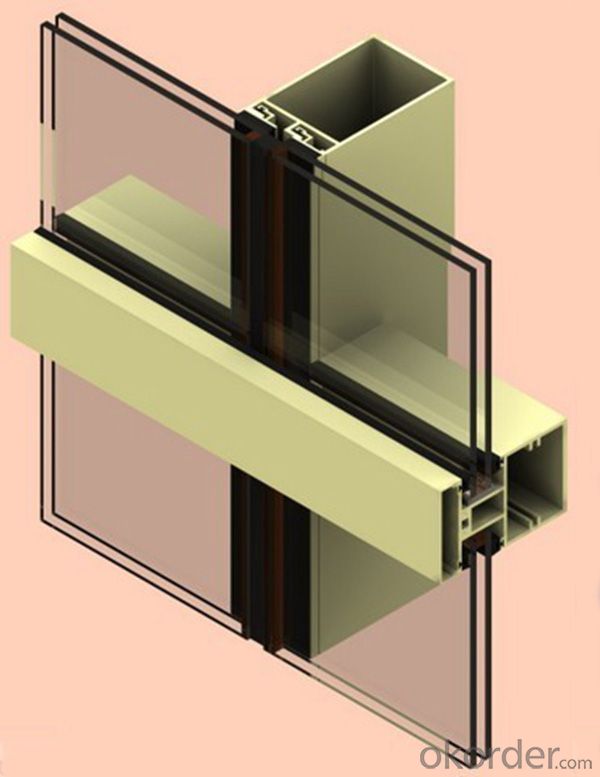

5. Image of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

6. Package and shipping of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q:How do aluminum profiles contribute to sustainable transportation solutions?

- Aluminum profiles contribute to sustainable transportation solutions in several ways. Firstly, aluminum is a lightweight material, which means it can help reduce the overall weight of vehicles. This, in turn, improves fuel efficiency and reduces carbon emissions. Additionally, aluminum profiles are highly durable and corrosion-resistant, leading to longer lifespan and reduced maintenance requirements. Furthermore, aluminum is recyclable, allowing for the reuse of the material in other applications, thus reducing the need for new production and minimizing waste. Overall, the use of aluminum profiles in transportation helps promote sustainability by improving fuel efficiency, reducing emissions, and minimizing resource consumption.

- Q:Are aluminum profiles suitable for medical equipment?

- Indeed, medical equipment finds aluminum profiles to be highly suitable. Aluminum, being a material that is both lightweight and strong, exhibits exceptional resistance to corrosion, thereby rendering it exceptionally appropriate for deployment in medical equipment. The ease with which aluminum can be transformed into diverse profiles and shapes further enhances its ability to meet specific demands. Moreover, aluminum possesses non-toxic, non-magnetic characteristics, and can be readily sterilized, thus rendering it completely safe for employment in medical settings. Furthermore, its capacity to withstand wear and tear, along with its durability, further amplifies its suitability for medical equipment, thereby ensuring extended and dependable functionality.

- Q:Aluminum profile connecting piece

- Very little to buy this alone, and only with industrial aluminum suppliers. - selling on Taobao is also a way if the price is appropriate.

- Q:in addition to the groove width is not the same as other well differentiated? Is there any difference in wall thickness?

- There must be a difference. There is a distinction between rice weight and wall thickness. For example, Jing Teng Aluminum CompanyJT-8-5050W meters weight is 3.25KG,,JT-10-5050 meters weight is 2.95KG. Specific parameters, you can go to consult the next business

- Q:What are the different anodizing colors available for aluminum profiles?

- There are several different anodizing colors available for aluminum profiles, including clear, black, bronze, gold, and champagne.

- Q:How do aluminum profiles perform in terms of water resistance?

- Aluminum profiles generally exhibit good water resistance due to their natural properties. The metal itself is corrosion-resistant, which means it does not easily rust or degrade when exposed to water. Additionally, aluminum profiles can be further treated with coatings or anodization processes to enhance their water resistance capabilities. These surface treatments create a protective layer that prevents water from penetrating the metal, reducing the risk of damage or deterioration over time. However, it is important to note that the water resistance of aluminum profiles can vary depending on the specific alloy, surface treatment, and maintenance practices. Regular cleaning and proper sealing of joints can help ensure optimal water resistance performance.

- Q:For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

- Q:Are aluminum profiles compatible with glass?

- Glass is compatible with aluminum profiles. In different applications like windows, doors, curtain walls, and partitions, aluminum frames are often used as framing systems for glass panels. This compatibility is due to aluminum's lightweight, durability, and resistance to corrosion, which make it an excellent material for holding and supporting glass panels. By using different profile designs, aluminum frames can securely hold glass of various types and thicknesses, giving structural stability and enhancing the overall appearance. Furthermore, aluminum profiles can be customized and engineered to meet specific glass installation needs, ensuring a perfect fit and compatibility between the two materials.

- Q:What is aluminum profile?

- Aluminum is the aluminum bar through hot melt, extrusion, so as to obtain different cross-section of aluminum. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoresis coating, fluorine carbon spraying, powder spraying, grain transfer and other processes.

- Q:How to prevent the aging of aluminum profile hardness is not enough?

- Raw materials, alloy, cast bar qualityDuring extrusion, the outlet temperature is guaranteed to be above the solid solution temperature,Cooling, quenching speed guaranteed as fast as possible

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords