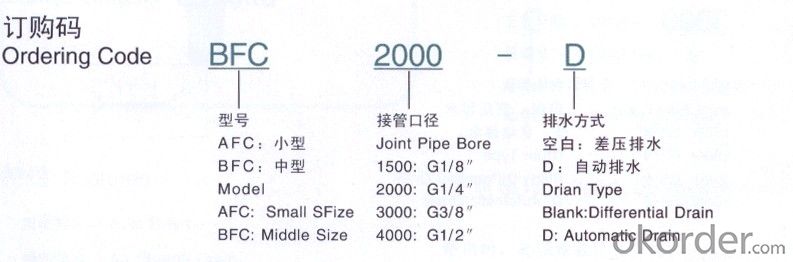

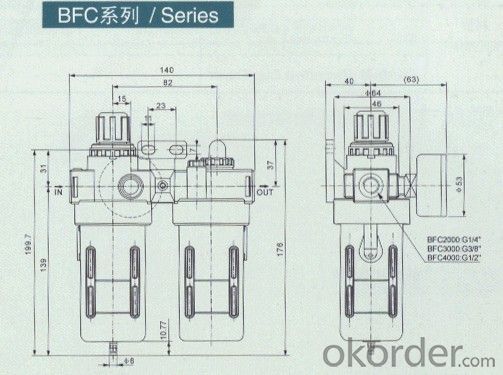

AIR FILTER BFC-4000 6"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

free to adjust the pressure range ,reduce the impurity of air .oil and water seperator .

best solution for automation . strict quality and cost control system !

feature :1.simple assemble,instructure simple ,use to all kinds of automatic equipment .

2.sugest oil : VG32

3.pay attention to the temperation range and pressure range .

advantage: 1.new oil cap to ensure the oil will not come out .

2.new adjust pressure cap ( when pressure high will not come out)

3. bigger flow rate and less noise .

production ability : 1. one month 10000pcs

2. 150 workers

3 .advanced machine ,professional technician team

4. 4.delivery date :normally 15-20days .

2.sugest oil : VG32

3.pay attention to the temperation range and pressure range .

advantage: 1.new oil cap to ensure the oil will not come out .

2.new adjust pressure cap ( when pressure high will not come out)

3. bigger flow rate and less noise .

production ability : 1. one month 10000pcs

2. 150 workers

3 .advanced machine ,professional technician team

4. 4.delivery date :normally 15-20days .

best solution for automation most professional manufacture for pneumatic !

- Q:Pneumatic valve, solenoid valve, pneumatic instrument work, air pressure in what range is appropriate?

- Pneumatic valve, solenoid valve, pneumatic instrument, air pressure in the 0.5Mpa~0.63Mpa (ie: 5~6.3kg/cm2) range is appropriate. Most of the work pressure on the use of pneumatic equipment in the industry is about 0.55Mpa. (i.e.: 5.5kg/cm2 or so). I hope I can help you.

- Q:A brief description of pneumatic three element and its function

- The pneumatic three element is composed of a water separator, an air filter, a pressure regulating valve and an oil sprayer.The function of the utility model is that a water filter is used for filtering water, impurities, particles, etc. in compressed air

- Q:What does pneumatic component mean?

- Commonly used are cylinders, solenoid valves, pressure regulating valves, pneumatic motors, filters, couplings, oil and water separators, and so on, each component contains a very wide range of categories

- Q:What are the advantages of pneumatic components?

- 5, the use of compressed air, storage energy, to achieve centralized gas supply. It can release energy in short time to obtain high speed response in intermittent motion. Buffer can be realized. Strong adaptability to impact load and over load. Under certain conditions, the pneumatic device has the ability of self preservation.6 、 all pneumatic control, with fire prevention, explosion proof, moisture-proof ability. Compared with hydraulic method, pneumatic mode can be used in high temperature situation. 7, because the air flow loss is small, compressed air can be centralized supply, long-distance transmission.

- Q:What are the classifications of cylinders in pneumatic components?

- The cylinder is one of the most widely used pneumatic actuators in pneumatic systems. Depending on the conditions of use, the structural characteristics of different, the use of different functions, installation of different forms are classified as follows:

- Q:What is the function of the oil sprayer in the pneumatic components, such as the AIRTAC model of AL2000?

- For example, solenoid valve, cylinder to provide oil mist play a role in lubrication.

- Q:Pneumatic oil filter oil in what

- Oil mist cup lubricating oil level height can not exceed the total height of the 3/4 cup, oil: turbine oil No. 1 (International designation: ISO VG32), its properties are very thin viscosity of 7E degrees (the equivalent of lubricating oil, sewing machine oil 5E ~7E degrees); GB grade: 7 machine the lubricating oil (viscosity 7E degrees), sewing machine oil, is also more convenient choice.

- Q:I would like to ask you, pneumatic components, including what mechanical parts?

- Pneumatic components mainly include gas source treatment (triple parts, filters, pressure reducing valves, etc.)

- Q:Why is there any white thing on the outer thread of the pneumatic element PC?

- The raw material belt is a kind of auxiliary material commonly used in the plumbing and heating installation. It is used to connect the pipe fittings and enhance the tightness of the pipe connection. Raw materials with chemical name is PTFE, HVAC and water supply and drainage in the widespread use of ordinary white Teflon tape, and natural gas pipelines also have a special Teflon tape, in fact, the main raw material for PTFE, but some process. The raw meal band is a novel and ideal sealing material. Because of its non-toxic, tasteless, excellent sealing, insulation and corrosion resistance, it has been widely used in water treatment, natural gas, chemical, plastics, electronic engineering and other fields

- Q:Pneumatic components of SMC pneumatic components

- The widespread use of oil-free lubrication technology, to meet some special requirements. Due to the environmental pollution and the requirements of electronic, medical, food and other industries, the oil is not allowed in the environment, so no oil lubrication is the development trend of pneumatic components, and no oil lubrication system can be simplified. The mist sprayer in European market is out of phase, and oil-free lubrication has been widely used. In addition, in order to meet some special requirements, deodorization, sterilization and precision filter are being developed. The filtration accuracy has reached 0.1~0.3 m, and the filtration efficiency has reached 99.9999%.In view of some special requirements, it is widely acknowledged that improving and developing pneumatic products can occupy a market and obtain small economic benefits. Ji'nan Huaneng pneumatic components company has developed the cylinder and valve for the special requirements of railway marshalling and wheel rail lubrication, which has attracted the attention of the railway sector. The use of new materials, combined with the new technology. The development of foreign film dryer, the dryer using reverse osmosis membrane filters technology to the compressed air in the water, energy saving, long service life, high reliability, small volume, light weight and other characteristics, is suitable for the flow of small occasions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 6"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords