AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

· Air source treatment unit includes filter regulator and lubricator, It is in standard modular design and can freely separate and combine.

· Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically.

· Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

· Lubricator is an element that can provide good lubrication for pneumatic system, with novel structure and easy adjustment of oil drip.

AIRTAC Air Filter Combination AFC2000 FR.L With Pressue Gauge

BFC2000 Two-point Combination Filter&Regulator Lubricator Air Units

BFC 3000 air combination filter regulator lubricator pressure regulator pneumatic component air unit air compressor

1/2'' BFC4000 Adjustable Pressure Air Source Treatment Unit

Air Source Treatment Air Filter Pneumatic Regulator Lubricator 0.5-9.0Kgf/cm2

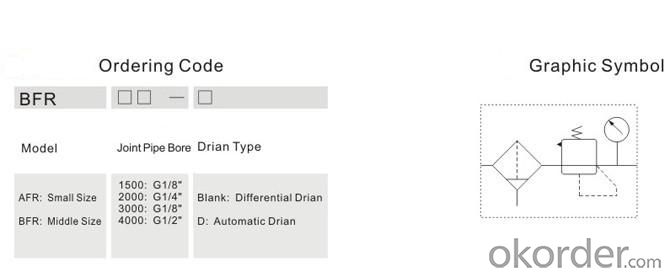

Ordering code:

Specification:

We manufacture all important parts by ourself to insure the quality, such as filter core. Outsourcing parts were selected and tested very strictly. Auto Drain can be selected.

- Q:What are the main parameters of pneumatic components?

- Go online and find a parameter list of the pneumatic components you need;There are differences in pneumatic components for different uses.

- Q:Such as pneumatic machines, pneumatic stamping machine, please ask where it came from, how come, I saw a few pipes connected to a small machine, is that pneumatic valve? As long as you buy that, will it work?

- 3 pneumatic valve: driven by compressed air valve. Clear only when the pneumatic valve procurement specifications, type, working pressure to meet the procurement requirements of the practice, in the current environment of market economy is not perfect because the pneumatic valve manufacturer for the product competition, each are in the pneumatic valve under the concept of unified design, with different innovations, formed the enterprise standard and product individuality. Therefore, in the pneumatic valve procurement, more detailed technical requirements and coordination with manufacturers to obtain consensus, as pneumatic valve procurement contract annex is very necessary.

- Q:I don't understand. To the assembly of pneumatic components factory, so that the understanding of the product is faster?. I hope there are teachers in this area to help answer. How long is the assembly done?

- Find a bigger shop learning in Yangzhou for a period of time or pneumatic

- Q:Pneumatic components, characters, symbolsMuffler, throttle valve, cylinder, pneumatic valve, etc.

- Pneumatic valve: 2 2 valve /2 3 valve /3 4 valve /3 5 valve / valve / quick exhaust valve / dual pressure valve / adjustable one-way throttle valve / pressure sequence valve / vacuum control valve / delay valve, normally open / delay valve, often closed / gas control valve / stepping module, TAA

- Q:What are the components of a cylinder in a pneumatic system?

- The act or function of performing pneumatic system designs.

- Q:What are the pneumatic components used in the automatic production line?

- Cylinder, rotary joint (also called oil distributor), solenoid valve, sensor, vacuum chuck

- Q:What is the control principle of the pneumatic three jaw chuck? How does the pneumatic component control the chuck, then how does the chuck connect to the spindle? If a satisfactory answer will chongxie! most

- You can only answer your previous question. How does the pneumatic component control the three jaw chuck?:The three jaw chuck is also a kind of cylinder, but the connecting rod is added to the piston rod of the cylinder to form two claws or three claws.So the pneumatic component is the principle of controlling the air claw, the same as the principle of controlling the cylinder

- Q:Pneumatic components, three bit, five - way, can you explain?

- This refers to: solenoid valve function.Three: solenoid valve spool has three working position (A coil energized 1 positions, B coil energized 1 positions.

- Q:Pneumatic components of SMC pneumatic components

- An element of a pneumatic element that does work by the pressure of the gas or by the force of its expansion is the component of the elastic energy of the compressed air that is converted to kinetic energy. Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic component is a kind of power transmission method. It is also an energy conversion device and uses gas pressure to transfer energy. 1. The layout of pneumatic equipment is simple and convenient, and the equipment protection is simple. Medium for air, compared to the hydraulic medium is not easy to burn, so the use of safety.2, the operating medium is inexhaustible air, the air itself does not cost money. The exhaust disposal is simple, without polluting the environment and low cost.3, the output power and operation speed adjustment is very simple. The speed of the cylinder is usually less than 1M/S, faster than the hydraulic and electrical methods of action.4, high reliability, long using life expectancy. The number of useful measures of electrical components is about a million times, and usually the solenoid valve life is greater than 30 million times, some good quality valves beyond 200 million times.

- Q:Pneumatic components, those equipment needs to be used, specific points. Additional reward

- It must be the executing agency. If you want to do such sales, you can run automated equipment, automated assembly line manufacturers, such companies, pneumatic components should be used more!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords