AIR FILTER BFC-4000 2”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

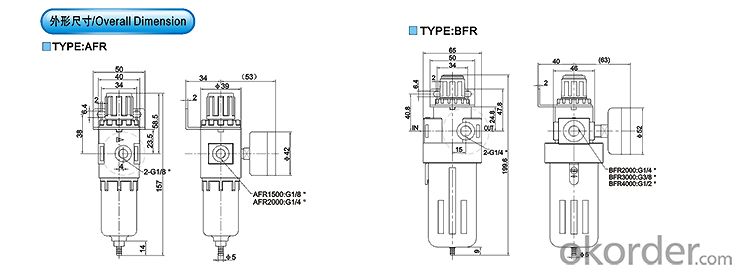

Type

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

- Q:It is a standard pneumatic drive element. What functions does it have on the cylinder?

- Two 、 wear rule of cylinder and its reason(1) the wear rule of cylinderFrom the longitudinal section of the cylinder (along the axis of the cylinder): irregular, tapered, or tapered". The maximum wear parts: cylinder with the piston at TDC on the first piston ring corresponding to the upper reach of the piston ring wear, cylinder order form "". Under special circumstances, the location of the maximum cylinder wear in the middle (drum). On the same engine, the wear of different cylinders is different. The wear of the front wall of the first cylinder and the back wall of the last cylinder of the water cooled engine is more serious.From the cross section of the cylinder: uneven wear, wear irregular oval. Each cylinder along the circumferential direction of the maximum wear parts: general is the intake valve near the wall opposite the maximum wear.

- Q:What does pneumatic component mean?

- Commonly used are cylinders, solenoid valves, pressure regulating valves, pneumatic motors, filters, couplings, oil and water separators, and so on, each component contains a very wide range of categories

- Q:What are the pneumatic components used in the industry?

- For example, I often see the pneumatic clamping, air hammer, pipeline transport and sorting,

- Q:What are the advantages of pneumatic components?

- 2, the working medium is inexhaustible air, the air itself does not cost money. The utility model has the advantages of simple air handling, no environmental pollution and low cost. 3, the output force and work speed adjustment is very easy. The speed of the cylinder is generally less than 1M/S, faster than the hydraulic and electrical methods of action.4 、 high reliability and long service life. Electrical components of the effective action of about a million times, while the general electromagnetic valve life of more than 30 million times, and some good quality valve more than 200 million times.

- Q:I don't understand. To the assembly of pneumatic components factory, so that the understanding of the product is faster?. I hope there are teachers in this area to help answer. How long is the assembly done?

- The light assembly is not enough, but also know its working principle, if you have time to go to the assembly shop of pneumatic machine practice, various pieces of mastery is impossible, as long as the common thing to do that on the line, almost a year

- Q:What are the special advantages of the pneumatic device of a vibrating screen?

- 5, the use of compressed air, storage energy, to achieve centralized gas supply. It can release energy in short time to obtain high speed response in intermittent motion. Buffer can be realized. Strong adaptability to impact load and over load. Under certain conditions, the pneumatic device has the ability of self preservation.6 、 all pneumatic control, with fire prevention, explosion proof, moisture-proof ability. Compared with hydraulic method, pneumatic mode can be used in high temperature situation. 7, because the air flow loss is small, compressed air can be centralized supply, long-distance transmission.

- Q:Which three pneumatic components are three?

- Water separator, air filter, voltage regulator, oil sprayer.Water from the gas source contains moisture and should separate the moisture from the air before it enters the actuating element (cylinder, pneumatic motor) to prevent rusting of the actuating element. Water separator gas filter used in this section.

- Q:Advantages of pneumatic components?The pneumatic device has simple structure, handiness and simple installation and maintenance

- Pneumatic valve automatic temperature control technology is used in mixing with water cooling device, to determine the mixed water temperature by a temperature sensing element of self operated temperature control valve, and according to the variation of water temperature control switch installed in the valve passage inlet temperature, thereby changing the heat into the water. The pneumatic valve can indirectly control the water inlet by controlling the backwater quantity. The structure is simple, and the cost is low. At run time if the outage situation, temperature control part can still play a very good protective effect. At the same time, the pneumatic valve with electric actuator water cooling device, to determine the indoor temperature by a temperature sensing element of electric heating type remote temperature control valve, and according to the regulation of water temperature changes in high temperature water inlet valve installed in the channel. The advantages of the mixed water cooling device mainly includes temperature controller can be used to control the temperature, temperature range adjustable; temperature controller can be set for the opening and closing time, easy to control, can increase the other kinds of intelligent control functions; electric drive safety, electric three-way valve is not easy to be blocked, has a good ability to adapt to the water quality.

- Q:Can nitrogen be used as the source of air for pneumatic valves? Generally use compressed air as pneumatic components of the gas source, suddenly asked customers can use nitrogen

- YesPneumatic valve, as long as the gas pressure can reach nine OK ah!The use of air is simple, convenient and free of charge

- Q:What is the control principle of the pneumatic three jaw chuck? How does the pneumatic component control the chuck, then how does the chuck connect to the spindle? If a satisfactory answer will chongxie! most

- The 3 claws move synchronously to the center, clamping the target workpiece, and when the electromagnetic valve is powered off, the 3 claws will be released simultaneously and reset. In order to solve the gas claw used in rotating occasions, you can use the "rotary joint", is 2 in 2 out of that, one end of the rotary joint is connected with the gas claw, the other end is connected with the fixed end, that can achieve the rotation function of gas claw.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 2”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords