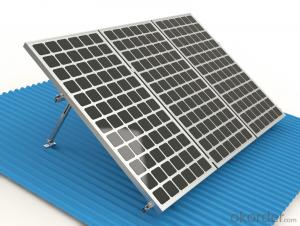

Adjustable Flat Rooftop Solar Mount

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Adjustable Flat Rooftop Solar Mount

Flat Roof Racking system is developed to mount the module tilt a certain angle on a flat roof or ground. You can have

the fixed or adjustable angle solution as 10-15deg, 15-30deg and 30-60deg according to your exact requirement. GS series

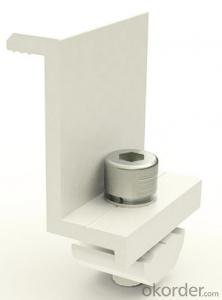

product have the innovated aluminum rail, D-module, clamps and legs which can be pre-assembled to make the installation

easy and quick for saving your labor cost and time. Besides, the customized length of rail will not require onsite weld and

cut, keeping the appearance entirety, structural strength and anti-corrosive performance.

Specifications

Solar Roof Mounting System :

1) ISO 9001,AS/NZS 1170&TUV certified

2) Fit all kinds of panels

3) Easy installation

Solar Roof Mounting System :

Material | Aluminum AL6005-T5 & SUS 304 |

Standard | AS/NZS 1170, TUV |

Install Site | Flat Roof |

Install Angle | 0-60 degree |

Max Building Height | 20 m |

Wind load | 130mph(60m/s) |

Snow Load | 30psf(1.4kN/m2) |

Anticorrosive | Anodized or hot galvanized |

Color | Natural or Customized |

Warranty | 10 years |

Duration | More than 20 years |

Fixed System

- Q:Are there any specific requirements for streetlight or outdoor lighting design when using a solar mounting system?

- Yes, there are specific requirements for streetlight or outdoor lighting design when using a solar mounting system. The solar mounting system should be designed in a way that maximizes the exposure to sunlight, ensuring optimal energy generation. Additionally, the lighting fixtures should be positioned and directed to effectively illuminate the desired areas, considering factors such as brightness, coverage, and light distribution. It is also important to ensure proper wiring and connectivity between the solar panels, batteries, and lighting fixtures to ensure efficient and reliable operation.

- Q:Can a solar mounting system be used in areas with solar grants for nonprofits?

- Yes, a solar mounting system can be used in areas with solar grants for nonprofits. These grants are specifically designed to support nonprofit organizations in adopting renewable energy solutions such as solar power. By installing a solar mounting system, nonprofits can take advantage of these grants to offset the cost of the system and reduce their reliance on traditional energy sources.

- Q:What are the benefits of using a solar mounting system?

- The benefits of using a solar mounting system include increased efficiency in harnessing solar energy, improved safety and durability of solar panels, flexibility in installation options, and potential cost savings in the long run due to reduced maintenance and increased energy production.

- Q:How does the cost of a solar mounting system compare to the cost of solar panels?

- The cost of a solar mounting system is typically a fraction of the cost of solar panels. While the exact proportion may vary depending on the specific system and installation requirements, solar panels generally represent the majority of the overall cost of a solar energy system.

- Q:Can solar mounting systems be installed on rooftops with rooftop access hatches?

- Yes, solar mounting systems can be installed on rooftops with rooftop access hatches. These hatches can be easily incorporated into the design and installation of the solar mounting system, ensuring convenient access while maintaining the functionality and stability of the solar panels.

- Q:Can a solar mounting system be used in areas with limited access to solar advocacy groups?

- Yes, a solar mounting system can be used in areas with limited access to solar advocacy groups. Solar mounting systems are primarily designed to support solar panels and ensure their stability and efficiency. While solar advocacy groups can provide valuable resources and information, they are not essential for the installation and operation of a solar mounting system. As long as individuals or organizations have the necessary knowledge and resources to install and maintain the system, they can harness the benefits of solar energy even in areas with limited access to solar advocacy groups.

- Q:Can a solar mounting system be used in areas with limited access to solar podcasts?

- Yes, a solar mounting system can be used in areas with limited access to solar podcasts. Solar mounting systems are designed to support and secure solar panels in place, ensuring optimal exposure to sunlight for maximum energy generation. While solar podcasts may provide valuable information on solar technology and maintenance, they are not essential for the installation or functioning of a solar mounting system. The system's effectiveness primarily relies on proper installation and positioning of the solar panels to capture sunlight effectively.

- Q:Can solar mounting systems be installed on flat ground?

- Yes, solar mounting systems can be installed on flat ground. Flat ground provides a stable and convenient surface for installing solar panels.

- Q:What is the expected maintenance cost for a solar mounting system?

- The expected maintenance cost for a solar mounting system can vary depending on various factors such as the type of system, quality of components, installation practices, and local environmental conditions. However, in general, solar mounting systems are designed to be low-maintenance and have minimal ongoing costs. Routine maintenance tasks may include inspecting and cleaning the panels, checking for loose connections or damaged components, and ensuring proper alignment of the system. These tasks can typically be carried out by the system owner or a professional solar installer. Overall, the expected maintenance cost for a solar mounting system is relatively low compared to other renewable energy systems.

- Q:Can solar mounting systems be installed on shingle roofs?

- Yes, solar mounting systems can be installed on shingle roofs. However, it is important to ensure that the installation is done correctly to avoid damaging the roof and to maximize the efficiency of the solar panels. Professional installation is recommended to ensure proper mounting and to adhere to any local building codes or regulations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Flat Rooftop Solar Mount

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords