Adjustable Arced Steel for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

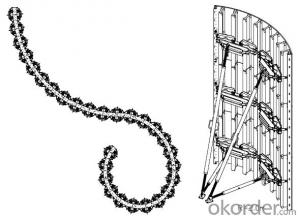

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q:Can steel formwork be used for industrial structures?

- Yes, steel formwork can be used for industrial structures. Steel is a strong and durable material that can withstand heavy loads and provide excellent support for large-scale construction projects. It is often preferred for industrial structures due to its high strength-to-weight ratio, resistance to fire and corrosion, and ability to be reused multiple times. Steel formwork systems offer flexibility, cost-effectiveness, and efficiency in constructing various types of industrial structures such as factories, warehouses, power plants, and refineries.

- Q:Is steel formwork suitable for high-rise construction?

- High-rise construction can indeed utilize steel formwork, which offers numerous advantages. Firstly, steel formwork possesses exceptional strength and durability, enabling it to withstand the immense pressures and loads associated with tall building construction. This feature ensures the safety and stability of the structure throughout the construction process. Secondly, steel formwork boasts exceptional versatility, allowing for easy customization to meet the specific requirements of high-rise construction. It can be designed and fabricated into various shapes and sizes, providing flexibility in creating different structural elements like walls, columns, and slabs. This adaptability facilitates efficient construction and minimizes the need for extensive modifications or adjustments. Moreover, the reusability of steel formwork makes it a cost-effective option for high-rise construction projects. By eliminating the constant need for new formwork materials, the overall construction costs are reduced. This sustainability aspect also contributes to minimizing waste and promoting resource efficiency. Furthermore, steel formwork ensures high-quality construction for high-rise buildings through its ability to provide a smooth and even surface finish. This characteristic eliminates the requirement for extensive plastering or finishing works, saving time and resources during the construction process. In conclusion, steel formwork is an excellent choice for high-rise construction due to its strength, versatility, reusability, and ability to provide a smooth finish. These qualities make it an ideal option for efficiently and effectively constructing tall buildings.

- Q:What type of finishes can be achieved with steel formwork?

- Steel formwork can achieve a variety of finishes, including smooth, textured, and patterned surfaces. Additionally, steel formwork allows for precise and intricate detailing, making it possible to achieve complex shapes and designs in concrete structures.

- Q:Can steel formwork be used for both horizontal and vertical concrete elements?

- Yes, steel formwork can be used for both horizontal and vertical concrete elements. Steel formwork provides strength, stability, and durability, making it suitable for a wide range of construction projects. Its versatility allows for the creation of various shapes and sizes, making it a preferred choice for both horizontal slabs and vertical walls.

- Q:What are the safety considerations when using steel formwork?

- When using steel formwork, there are several safety considerations that need to be taken into account. Firstly, it is important to ensure that the formwork is properly installed and secured to prevent any collapses or accidents. Regular inspections should be conducted to check for any signs of wear or damage that could compromise its stability. Another safety consideration is the proper handling and storage of steel formwork. It can be heavy and cumbersome, so workers should be trained in proper lifting techniques to avoid strains or injuries. Adequate storage facilities should be provided to prevent any damage or tripping hazards. Additionally, when working with steel formwork, workers should wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety boots to protect themselves from any potential hazards or falling debris. They should also be trained in safe work practices, including proper use of tools and equipment, as well as the correct procedures for dismantling the formwork after use. Overall, by following these safety considerations, the risks associated with using steel formwork can be minimized, ensuring a safe working environment for all involved.

- Q:Can steel formwork be used for both large and small-scale construction projects?

- Steel formwork is applicable to both large and small-scale construction projects, thanks to its durability, strength, and flexibility. Its versatility allows it to meet the diverse demands of construction projects. Both large and small-scale projects can benefit from its ease of customization and adjustment to meet specific requirements. Moreover, steel formwork's reusability contributes to its cost-effectiveness for both types of projects. Furthermore, it guarantees a smooth and high-quality finish for concrete structures, enhancing the desired aesthetic appeal of both large and small-scale construction projects.

- Q:How does steel formwork compare to wooden formwork?

- Steel formwork is often considered superior to wooden formwork due to its numerous advantages. Firstly, steel formwork is highly durable and can withstand heavy loads and repeated use. It does not warp, crack or split like wooden formwork, ensuring a longer lifespan and reduced maintenance costs. Moreover, steel formwork provides greater accuracy and precision in construction. Its rigid structure ensures that the desired dimensions and shapes are maintained, resulting in better-quality finishes. In contrast, wooden formwork can be more challenging to align and may result in slight variations or imperfections in the final product. Steel formwork also offers increased efficiency and productivity. It can be easily assembled, disassembled, and moved to different locations, reducing construction time and labor costs. Additionally, steel formwork requires minimal cleaning and maintenance, eliminating the need for constant repairs or replacements like wooden formwork. Furthermore, steel formwork is more resistant to moisture and weather conditions. It does not absorb water or warp when exposed to rain or humidity, making it suitable for use in various climates. Wooden formwork, on the other hand, can degrade when exposed to moisture, potentially affecting the structural integrity of the construction. Although steel formwork may require a higher initial investment than wooden formwork, its long-term benefits outweigh the costs. It provides greater durability, accuracy, efficiency, and resistance to environmental factors, making it a preferred choice in modern construction projects.

- Q:Can steel formwork be used for precast concrete slabs with openings?

- Yes, steel formwork can be used for precast concrete slabs with openings. Steel formwork offers the flexibility and strength required to create openings in precast concrete slabs, ensuring precise and consistent results. Additionally, the durability and reusability of steel formwork make it a cost-effective choice for such applications.

- Q:How does steel formwork affect the overall construction budget?

- Steel formwork can have a significant impact on the overall construction budget. While it may initially have a higher upfront cost compared to other types of formwork, such as timber or plastic, it offers various advantages that can result in cost savings in the long run. One major advantage of steel formwork is its durability and reusability. Unlike timber or plastic formwork, steel formwork can withstand multiple uses without compromising its structural integrity. This means that it can be used for numerous construction projects, reducing the need for frequent replacements and lowering material costs over time. Additionally, steel formwork is known for its high strength and stability, allowing for efficient concrete pouring and ensuring precise and accurate dimensions. This reduces the risk of errors or reworks, which can lead to significant time and cost overruns. Furthermore, steel formwork typically requires less labor and time to assemble and dismantle compared to traditional formwork materials. Its modular design and ease of installation enable quicker construction progress, resulting in reduced labor costs and improved project efficiency. Moreover, steel formwork offers flexibility in design and customization, allowing for complex and intricate structures to be built with ease. This versatility can eliminate the need for additional materials or specialized formwork systems, resulting in cost savings. In summary, while steel formwork may have a higher initial cost, its durability, reusability, strength, and efficiency can lead to cost savings in terms of material, labor, and time. By considering the long-term benefits and overall efficiency it provides, steel formwork can positively impact the overall construction budget.

- Q:Can steel formwork be used for structures with high corrosion resistance requirements?

- No, steel formwork is not suitable for structures with high corrosion resistance requirements as steel is prone to corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Arced Steel for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords