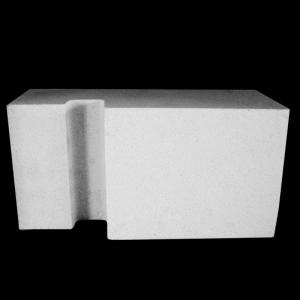

Acid Resistance Brick with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CMAX acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Quick Details

| Shape: | Material: | ||||

| SiO2 Content (%): | Al2O3 Content (%): | MgO Content (%): | |||

| CaO Content (%): | Refractoriness (Degree): | CrO Content (%): | |||

| SiC Content (%): | Model Number: | Brand Name: | |||

| Fe2O3 :: | Density:: | Water absorption:: | |||

| Acid fastness: | MOR: | Colour:: |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | 20days after receiving advance |

Specifications

1.good acid-resisting

2.high temperature

3.thermal insulation

4.best price with high quality

5.Long using time

- Q:Acid resistant brick lining, engineering scaffolding, how to take?

- Construction preparation, familiar with drawings, specifications, technical disclosure, do a good job of the handover process.

- Q:Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Acid etching is a chemical cleaning process to remove metal oxide and other impurities from the acid aqueous solution. As the acid and corrosion are more economical and suitable for continuous operation, it is the most effective way to remove the oxide surface of metal surface of large tonnage products. Especially cleaning iron and steel products, such as billets, ingots, steel plates, steel strips, wires, pipes and so on. Can also be used for steel forgings, casting cleaning, rust removal

- Q:The difference between polished tiles and glazed tiles?

- The brick is a brick block pattern, glazed tile surface is a layer of glaze, the following are the embryo is yellow brick, looks like that, for a long time, this layer of glaze will slowly worn away

- Q:Is acid proof brick alkali resistant?

- See, he made up, if it is relatively stable, but also a certain degree of alkaline resistance, of course, may be prone to caustic corrosion

- Q:What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q:What is acidproof ceramic tile?

- Ceramic tile is acid with quartz and feldspar, clay as the main raw material, acid resistant materials by high temperature firing, with acid of high, low water absorption, is not easy to be oxidized at room temperature, is not easy to be medium pollution characteristics.

- Q:Acid proof brick, acid resistant porcelain in the paste process with no seam

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q:98% acid tank cofferdam can use acid resistant brick?

- The operation temperature of some hot oil pumps in hydrogenation unit is higher, which is higher than the spontaneous ignition point of oil products. If there is leakage, it is prone to fire accidents. Therefore, the operation should pay attention to the operation of hot oil pump, pay attention to pump body, sealing and so on whether there is leakage, if leakage should be dealt with immediately.

- Q:How much is one square meter of acidproof tile?

- Acid resistant brick: resistance to pressure, corrosion resistance, easy to clean, acid and alkali; acid resistant tile prices generally around 40 yuan a square meter!

- Q:What is a thermal insulation castable?

- The thermal insulation castable is the castable with lower bulk density, the basic body is about 1.5. The castable contains many pores, low volume density, small thermal conductivity and good heat preservation effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acid Resistance Brick with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords