AAC Block Production Line,excellent, perfact

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

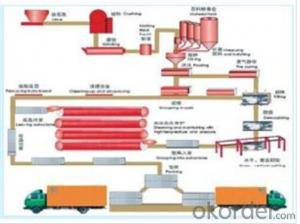

AAC block production line, also known as aerated concrete block line, is a kind of lightweight block production line. According to different types of raw materials, quality and processing characteristics of equipment, AAC block machines are differently designed. The production process is as follows: Mix fly ash or silica sand, slag and water into slurry, stir the slurry together with powdered lime, a certain amount of cement, plaster and foaming agent, and then pour them into the mold box. After resting foaming solidification, AAC lightweight block production line can cut them into blocks or plates in various specifications, and then send them into the autoclave by the steam-curing car. After high temperature and high pressure steam curing, AAC block machine can produce porous and light aerated concrete products. Adopting German advanced equipment, PLC automatic feeding and complete electric control system, our lightweight block production lines are quite famous both home and abroad. The whole aerated concrete block line includes feeding, mixing, pouring, preliminary maintenance, cutting, autoclaved maintenance, and so on.

Use of AAC Block Machine

AAC lightweight block production line is widely used in industrial and civil constructions. We adopt the most mature technology of production to produce building materials.

Advantages of Aerated Concrete Block Line

1. Without any exhaust gas or waste residue, the production process of AAC block machine is in accordance with national environmental protection policy.

2. This lightweight block production line is equipped with a dedusting system for boiler gas and dust disposal which meet the requirements of smoke prevention and dust control.

3. Dust collector is used to improve the production environment and working condition.

4. Waste water and condensate water produced from AAC block machine can be recycled and reused. Acoustic treatment should be taken to reduce noise produced by ball mill machine.

5. AAC lightweight block production line features light mass, high intensity, heat preservation, sound insulation, etc.

Technical Process Technologies of AAC Block Machine

1. Fixed Point Pouring

Our company uses fixed pouring to save factory space, which is easy for centralized control. Different from stationary pouring, it overcomes the defect that the latter pouring material hardens first and can not be cut. The lightweight block production line is also safe and health to operate.

2. Cutting Technology of AAC Block Machine

Aerated concrete blocks need to be put into the static room for thermal curing so as to accelerate the hardening of brick green body, reduce the body’s static time and improve the production efficiency. Bricks manufactured from AAC lightweight block production line are characterized by uniform density, good pore structure, high strength and good frost resistance. Our AAC blocks machines can produce products in winter. Environmental temperature will not result in the phenomenon of hard middle body but soft surrounding body. We adopt advanced turn-over cutting machines to carry out six surface cutting. The cutting technology features accurate size and beautiful appearance. This lightweight block production line also meets the national standards.

3. Steam Curing Process of AAC Block Machine

There are vacuum and exhaust types optional for customers. It must do procuring before steam curing. During the steam curing process, we adopt rapid raising pressure to reduce the curing time, improve production efficiency, make the product do not crack and acquire high product yield.

- Q:What are the differences between loaders, gearboxes and other brands of loaders manufactured by Shandong construction machinery?

- The difference between Qingzhou's large volume of engine power strong gearbox is high and low speed 1; 3 2:4 can be better suited to a variety of venues work work is two forward a back gear transmission system technology is now Shandong Shangong Carter's ability to adapt to the strong than Linyi

- Q:big machinery for tortilla making

- This okorder /

- Q:Our teacher has specifically asked us to search for the ACM definition of computer science, as well as its elements. I've been looking all over, but to no avail. Anyone mind helping me out?

- Computer Science Definition

- Q:Do you have a promising future in the foreign trade of machinery industry?

- Mechanical trade is very difficult to do, is the first mechanical product varieties and specifications is very complex, followed by the initial negotiation cycle of most large mechanical products is very long, so need comprehensive quality of participants is too high, it is generally difficult to do, or even into the machinery industry quickly back out.

- Q:What is defined in construction engineering as large machinery?

- The construction machinery models according to its performance and value can be divided into large, medium and small type, four

- Q:Any known malfunctions on surgical machineries?

- Regardless of the dangers from the surgical robot, many people still flock to hospitals that provide medication and treatments using the surgical machinery. Based on studies, this might be because patients have a tendency to think about the marketing guides of hospitals on their own websites as seen on medical health advice from doctors.

- Q:I wanna know why is machinery production more effective than labor?

- It doesn't get a pay check. It doesn't get tired. I can go all night. It doesn't make stupid mistakes.

- Q:humanity have acknowledge all inventions from lighter to x-rays and to infrared, and to ultraviolet rays,electromagnetic propulsions and space travel -seems to provide great assistance to humanity-yet, cancer, AIDS, parkinsons,alzhimers have no cure at all??,global warming,wars etc.. so is science missing A LOT from REALITY??

- Sixty years ago the brand-new technological 'gee-whiz' gadget was television. And it was universally acknowledged that it would be probably the greatest advancement in education since the printed book. So go watch 'South Park', 'MTV', 'SNL', and a few dozen other mindless sitcoms and ask yourself, What went wrong? People tend to get the kind of Government that they deserve. Henry David Thoreau Doug

- Q:Like make it gone forever. Just dirt. Tree's aren't a problem but the other small plants are. I have some land that i go to shoot on and its overgrown. So id like to make it look a little better and i want to lesson the amount of ticks and snakes if that's possible. ( i cant mow on account of rocks, junk, etc)

- well, okorder /

- Q:A short extract from the link below: A lawyer for one of the so-called Tapas Nine has confirmed to the Spanish newspaper El Mundo that their client would like to speak further to the Portuguese police but feels reluctant to do so because of Gerry and Kate McCann’s powerful political allies. You can read the rest in:http://www.newsdeskspecial .uk/2007/11/mccann-friend-a.html

- The machinery is only breaking down in the minds of guys like Adam Julia Peculiar etc. Portuguese police stated only yesterday that they had no case against the McCanns and that their lines of inquiry were running dry

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AAC Block Production Line,excellent, perfact

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords