AAC Block Making Machine ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

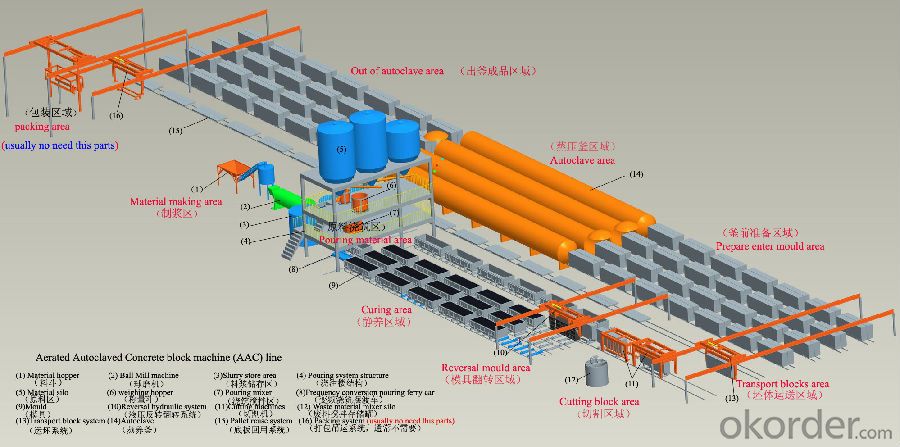

AAC Production Line

Item Description Remarks

1 A raw material processing

1.1 fly ash processing (grinding of fly ash)

1.2 fly ash hopper 1

1.3 fly ash conveyor belt 1

2 fly ash slurrying process

2.1 fly ash slurrying machine (including the shell and mixer) 1

2.2 transitional slurry tank mixer (pool is concrete structure) 2

2.3 fly ash slurry storage mixing tank (housing) 2

2.4 fly ash slurry storage mixing tank mixer 2

2.5 waste storage mixing tank (housing) 1

2.6 waste stored in stirred tank mixer 1

2.7 Pneumatic butterfly valve 2

2.8 manual butterfly 4

2.9 manual butterfly 5

2.1 slurry pump (liquid, 2.1 m deep) 3

3 ingredients slurrying process

3.1 fly ash slurry scale (including metering tank) 1

3.2 Lime, cement accumulation (including metering tank) 1

3.3 aluminum powder mixer 1

3.4 lime cement screw conveyor 2

3.6 casting inverter car ferry 1

4 the mold box and the mold bottom plate

4.1 mold box 20

4.2 mold bottom plate 140

5 Lifting handling and group mode

5.1 Flip crane 1

5.2 hydraulic flip spreader (including the hydraulic station) 1

5.3 care billet crane 1

5.4 prop blank spreader (including hydraulic station) 1

5.5 backplane return system 15

5.6 mold box movement system 5

6 cutting process

6.1 level cutting machine 1

6.2 interspersed with vertical cutting machine 1

6.3 cutting inverter level moving car 1

6.4 air compressor 1

6.5 waste suction hood 1

6.6 waste recycling mixer 1

7 autoclave curing process

7.1 prop blank car 60

7.2 mobile windlass 2

7.3 steering wheel 12

8 control system

8.1 electric control cabinet 1

9 lime process

9.1 The lime hopper (vibrator ZG405) 1

9.2 jaw crusher 1

9.3 bucket elevator 1 1

9.4 The electromagnetic vibrating feeder 1

9.5 Raymond (host) with the dust collector equipment 1

9.6 bucket elevator 2 1

10 dosing Floor

10.1 casting floor (customer self-built) 1

10.2 cement silo 1

10.3 Lime positions 1

Classifications of AAC production line equipment:

(1)By products: Annual output of 20000 cubic meters, 50000 cubic meters, 100000 cubic meters, 150000 cubic meters, 200000 cubic meters, 300000 cubic meters.

(2)By crafts: The ground turning cutting process, the air turning cutting process

(3)By materials: Fly ash aerated concrete production line, Sand aerated concrete production line, Slag aerated concrete production line.

Advantages of AAC block

1. Consumes Fly ash, which is a big problem for thermal power plants to dispose. It is environment friendly, because of no need of burning.

2. Higher strength, best thermal insulation & excellent sound absorption, vibration resistance compared to red bricks. The AAC product’s lightweight and easy workability means that is very quick to install on site and transportation with lesser brakeage.

3. AAC blocks made walls can be left exposed (without Plaster) and gains strength over time. It saves structural cost by 35% and recycling of breakage, rejects also.

4. AAC products are not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions.

5. AAC Block does not have any toxic substances or emit odors. Its production, management and disposal do not represent any health risks or damage to the environment. Its production process develops non-toxic gases.

6. AAC blocks are bigger in size then conventional bricks, resulting in lesser number of joints. Less joints result in lesser quantity of mortar required, resulting in saving of mortar.

- Q:Brick machine operating procedures

- Check the electrical part of the fault and leakage phenomenon. Check if the packing concentration is appropriate. Check the triangle belt tightness is appropriate. After the motor is fed to the upper part of the cylinder, open the material gate, so that the material flow to the feeding body cylinder, at this time presses began to work.

- Q:Maintenance method of fly ash brick machine

- the existence of "repair repair" thinking. There is no technical maintenance plan, the machine often with "disease" homework, only when the machine can no longer work, only sent to repair.

- Q:What is the difference between a vacuum brick machine and an ordinary brick machine?

- Vacuum brick machine than the ordinary brick machine more vacuum equipment, due to the use of vacuum, so you can improve the density of brick to reduce the water content of the brick, so the vacuum brick machine better quality.

- Q:Automatic concrete brick machine bearing how to choose?

- In order to ensure the safety of the operator and equipment, to stop the repair, adjustment and finishing operations in the machine operation, to prevent the opening of the door. When checking the fasteners can loose, you should point to see the rotor on both sides of the pressure plate hammer plate pressure plate screws;

- Q:Burning brick and autoclaved lime sand brick what different

- Autoclaved lime sand brick (standard brick) is made of fly ash or other slag or lime as raw material, adding lime, gypsum and aggregate, prepared by embryo material, pressed molding, high efficiency steam curing and other processes.

- Q:The scope of application of building waste brick machine

- The initial strength of the industrial waste slag-free brick is obtained during the brick forming process. Molding not only has a certain strength of the brick, and because of the close contact between the raw material particles to ensure that the physical and chemical effects between the particles can be carried out efficiently for the formation of late strength to provide the conditions.

- Q:What is the principle of vacuum brick machine

- static seal in the vacuum brick seal is relatively simple and easy to guarantee. If the sealing surface is not properly sealed, it is easy to cause the vacuum box to leak, so that the vacuum brick machine vacuum reduced, affecting its performance and product quality.

- Q:The development of brick machine

- Its environmental protection and energy conservation, the new wall by the country's affirmation.

- Q:How can a free brick brick brick machine be classified?

- According to the structure of the block: divided into a back cover block, not the back of the block, slot block, a slot block.

- Q:Brief introduction of cement brick machine

- This equipment is known as Mianshaozhuanji, that is to say the production of cement brick or hollow block, do not need sintering, through a short period of time can be shipped to the factory.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AAC Block Making Machine ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords