AAA Grade WBP Glue Film Faced Plywood for Construction Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: 1220*2440,1250*2500,915*1830

· Usage: Outdoor

· Grade: First-Class

· Main Material: poplar, birch, hardwood

· Formaldehyde Emission Standards: E2

· Plywood Type: 7-21ply

· Size: 1220*2440mm,1250*2500mm

· Thickness: 9-25mm

· Core: poplar, combi, hardwood

· Film: black, brown, red

· Glue: MR,WBP

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by seabundled by steel strip |

Delivery Detail: | within 15 days after receiving prepay or against origin L/C |

Product Specification:

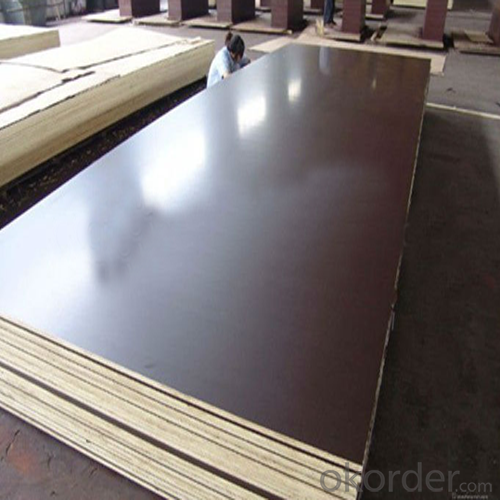

AAA grade WBP glue brown and black film faced plywood for concrete

Name | WBP glue Film faced plywood |

Film color | Black, brown, red (can print logo) |

Core Materials | poplar, combi, hardwood, birch |

Glue | MR, Melamine, WBP |

Size | 1220*2440*9-25mm 915*1830*9-25mm 1250*2500*9-25mm |

Moisture | 6-14% |

Modulus of rupture | more than 30Mpa |

Modulus of Elasticity | more than 6000Mpa |

Reuse times | more than 10 times |

Usage | Construction |

Packing | inside wrapped by 0.2mm plastic bag, outside by carton box and bundled by steel strip or as per your request |

Market | Asia, Middle East, Africa, Europe, Latin America, Ect. |

Certificate | ISO 9001,BV |

Payment terms | L/C, TT |

Delivery time | within 15days after receiving prepay or against origin L/C |

Product Feature:

1) High bending strength

2) little linear expansion con efficient

3) Strong nail holding

4) Moisture proof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If put in boilding water for 24 hours, it is still glue sticking and nondeformed.

10) If used abide by the illustration strictly, it can be reused more than 30 times

11) Solve the problems of leaking and rough surface during construction process, particular suitable for watering concrete.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

- Q:in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q:What are the benefits of color steel?

- Color steel sandwich panel is a color coated steel plate for the surface material, self-extinguishing type polystyrene, polyurethane, glass wool, rock wool as the core material, with heat curing adhesive in the continuous molding machine heating and pressing compound Of the ultra-light construction plate. (The thermal conductivity of the value of 0.034W / mk), the construction speed (no wet operation, do not do the second renovation, the construction period can be a small amount of light (for the concrete roof weight of 1/20 ~ 1/30), thermal insulation Shortening more than 40%), bright color (no surface decoration, color galvanized steel coating to maintain a period of 15 - 30 years) is a set of load, insulation, waterproof, decoration in one of the new envelope material.

- Q:New rock wool sandwich board polyurethane edge how much money one meter

- Do not do the fire to investigate or deal with either Yanmian board or polyurethane board price is the polyurethane invoice does not send about 130% of the price of rock wool

- Q:What is the difference between the board and the core board?

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than ... but generally do not choose the best! Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, ... plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

- Q:Is the foam sandwich board one meter high?

- Some we do the highest of 21 meters

- Q:Color steel 50 mm rock wool sandwich board one meter how much the price

- It is not normal to say that there is a flat between 40 and 50

- Q:What is the quota of the roof steel plate?

- Compression steel plate floor of the Caigang roof sandwich panels

- Q:With the production of sandwich panels can now control how many years?

- In general, sandwich panel covers the house! On the iron thickness of 0.4, under the thickness of 0.326, you can protect the new 10 years, no later than 2 years spray a paint, up to 25 years! Aluminized zinc is longer,

- Q:Color steel sandwich panels

- It depends on what grade you choose the color plate, including the surrounding environment and many other effects. The last one or two years on the rust rotten, the current market should be the best Baosteel color plate, but the price is more expensive, to the color steel sandwich board than the same level of other small manufacturers to 10 to 20 yuan Per meter, under normal circumstances, if you want to live for a long time, I suggest you do not use materials than low 0.5mm thick color plate, the general manufacturers can also use the color plate 8-15 years, if the board is too thin, then not Good to say, the thinner the color plate, the faster the corrosion, if the use of Baosteel's color plate, with more than 15 years should not be a problem. Due to price factors, the general small manufacturers do not have Baosteel color plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AAA Grade WBP Glue Film Faced Plywood for Construction Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords