AA3xxx Mill-Finished C.C Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA3xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA3xxx Mill-Finished Aluminum Sheets Used for Constructionis one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of AA3xxx Mill-Finished Aluminum Sheets Used for Construction

a.excellent quality,good credit;competitive price,comfortable service;Samples for free

b.fast delivery,small order accepted;Good rust resistance

c.We can control the delivery time within 35 days.

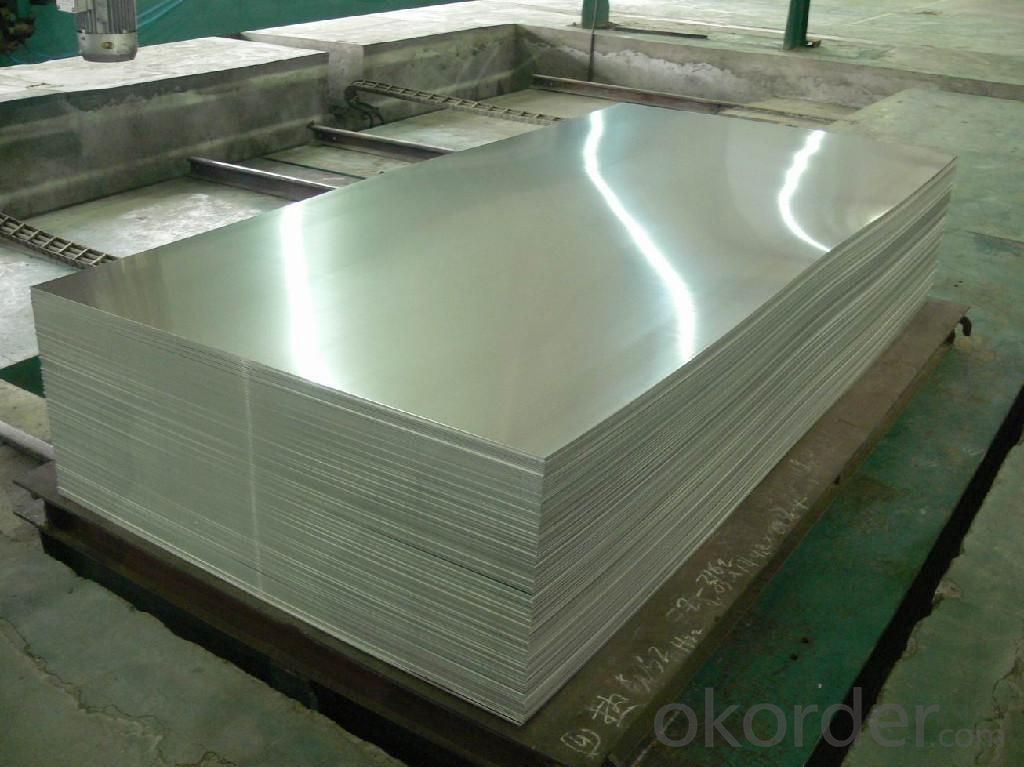

3.AA3xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA3xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA3xxx (AA3003 etc) |

Temper | H14, H16, H18, H22 |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mill-Finished Aluminum Sheets Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:When an aluminum bar and an iron bar are inserted into the water to conduct electricity, are there any floating objects? Why?

- It depends on what rods and electrodesWhen the iron rod is connected with the positive electrode of the power supply as an anode, the negative electrode connected with the power supply of the aluminum rod is used as the cathodeThe anode electrode is active metal, then the metal preferentially loses electronsThe iron reacts with electrons to produce ferrous ionsThe cathode is made of aluminum, so the metal does not get hydrogen ions in the electronsThe cathodic reaction of hydrogen ions leads to the formation of hydrogen and the alkaline enhancement of hydrogen cathodesTherefore, a large number of white floc near the cathode, immediately after the shock into gray green, exposure to air, long reddish brownWhen the aluminum rod is used as the anode of the power supply, the negative pole of the iron rod is connected with the cathode of the power supply as the cathodeBecause aluminum is a living metal, aluminum will lose electrons as an anodeThe anodic reaction leads to the loss of aluminum to trivalent aluminiumThe cathode react with hydrogen ions to change electrons into hydrogenIf water is to be produced by electrolysis of water, oxygen should be used as anode and the cathode material connected to the negative electrode of the power supply does not matter

- Q:What are the saw blades of the cutting aluminum bar? What are the cuts on the cutting surface?

- It depends on the characteristics of your saw machine to optimize the sawing effect...

- Q:How long is the length of the aluminum rod used in the production of the aluminum alloy line?

- As long as we know the rice weight of the aluminum rod used and the theory of the extruded section, we should choose the right length of aluminum bar

- Q:What can make the aluminum bar surface shiny?

- Aluminum is more complex. Aluminum itself is soft. Hand polishing is difficult to reach the mirror surface. Generally, the grinding force of the machine at high speed is used to reach the mirror surface

- Q:How much is an aluminum bar 3.5 in diameter?

- The market is generally 6 series aluminum rods.Aluminum rod is sold by ton, because the material is different, different grades, perhaps the average price of the Yangtze River or futures prices plus 500-1000 processing fees, but also tax, excluding freight.

- Q:Numerical control car diameter 10, length 70 aluminum bars, how to solve the earthquake mark?

- If my answer is helpful to you, please accept it as the best answer in time. Thank you!

- Q:such as squatting, forging, swing, roll, spinning, heat treatment and mechanical processingForged wheels is a heating temperature of 460 degrees in the aluminum rod by high-end technology after the squat swinging, spinning, forging, heat treatment and mechanical processing, forging Aluminum Alloy wheel through the inspection and the resulting coating. Share with you, where there is no room for supplementation

- Look, you can't change it this way:The hub is a kind of precision forging, precision forging, the aluminum bar heating by high-end technology spinning, heat treatment and NC machining, and then after the product inspection process to eliminate defects strictly, finally produce high quality precision forging Aluminum Alloy hub.

- Q:Which of the 6061 aluminum bars, heat treated and 7075 aluminum rods, has been treated with heat?

- Secondly, the different states also have great influence. From the highest hardness, 7 lines, 2 lines, 4 lines, 6 lines, 5 lines, 3 lines, 1 lines are reduced in turn. The range of 6061 is much larger than that of 7075.

- Q:What fuel does the aluminum rod heater cost most?

- Look at the quality you require. If the quality is not very high, it should be the cheapest gas. But this seems not to be used right now. Most of what I do now is made of natural gas, depending on the region, the cost, the cost

- Q:In cutting aluminum rods, the teeth of the disc saw are occasionally knocked out. How can they be avoided?

- The forward (feed) speed is a little slower to avoid.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA3xxx Mill-Finished C.C Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products