AA3xxx Mill-Finished Aluminum Strips Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of AA3xxx Mill-Finished Aluminum Strips Used for Construction Description

AA3xxx Mill-Finished Aluminum Strips Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Mill-Finished Aluminum Strips Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Mill-Finished Aluminum Strips Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

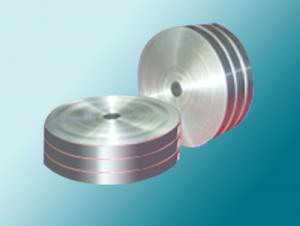

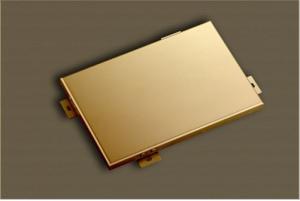

3.AA3xxx Mill-Finished Aluminum Strips Used for Construction Images

4.AA3xxx Mill-Finished Aluminum Strips Used for Construction Specification

Alloy | AA3xxx (AA3003 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mill-Finished Aluminum Strips Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA3xxx Mill-Finished Aluminum Strips Used for Construction.

B.When will you deliver the products?

AA3xxx Mill-Finished Aluminum Strips Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q:Aluminum and aluminum plate What is the difference between ah

- The following is true: 1, the number of layers: aluminum veneer is divided into two layers, the surface is aluminum, the second layer of plastic, aluminum-plastic plate is divided into three layers: the surface and the third layer of all aluminum, 2, the quality is different: because the aluminum veneer than the aluminum plate less aluminum, so the quality of aluminum veneer than the aluminum plate must be worse; 3, the price of aluminum veneer than aluminum Different: aluminum veneer than aluminum-plastic plate should be cheap, aluminum veneer positioning for the low-grade, aluminum-plastic plate according to the thickness of aluminum and the middle of the plastic with good and bad thickness into different grades, but certainly better than aluminum veneer ; 4, the construction effect is certainly not the same: a little aluminum-plastic plate can be slotted bending, turning construction, for a variety of occasions construction, but the aluminum veneer can not slot, bending, and because the bottom of the plastic, sticky Then the effect is not as good as aluminum-plastic plate.

- Q:I want to open a small aluminum-plastic plate factory, how much money

- Then the five major raw materials, protective film, aluminum roll, polymer film, paint, core material, if only on the composite line, then the paint and aluminum roll can be saved, you can directly purchase. The protective film, polymer film and plastic need to buy from the.

- Q:Home decoration, please curtain wall with aluminum plate how much the price per flat

- According to my knowledge, I say ~ aluminum-plastic composite board is a chemically treated aluminum plate for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials The The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials. I know that the general price is between 80 to 120 yuan This is what I know the information, I hope you have a reference role ~

- Q:Now sell a lot of aluminum-plastic plate, are OKorder auspicious aluminum-plastic plate, which is good?

- Yes ah, cloud like building materials is authentic

- Q:4mm thick aluminum-plastic plate, two-layer aluminum alloy thickness of 0.5mm price is how much?

- 135 ~ 150 yuan / square meter

- Q:Aluminum veneer and aluminum sheathed which fire?

- Aluminum veneer is more resistant to aluminum than plastic.

- Q:Facade billboard glass how much money a square about? How much money is a square thanks

- If you ask a separate material problem, then the aluminum-plastic board from 50-500 have some personal recommendations to buy about 100 yuan an area is 2.88 square aluminum thickness is 18 silk so, the glass is best about Is 60 yuan a square 5mm overall package to the production of steel frame is about 700 yuan a square

- Q:What is the quota of the ceiling plate?

- Set gypsum board ceiling, in the poor when the gypsum board material unit price into aluminum buckle plate unit price, other human machine machine content unchanged.

- Q:Aluminum plate. Aluminum plate. PVC plate plastic plate prices

- PVC board 10-16 yuan

- Q:What is the plastic core material of aluminum-plastic plate, where there is to sell?

- If you need the plate, you need to buy aluminum plastic plate manufacturers, they use plastic particles into a sheet, you can customize the length and thickness, width is generally 1220mm, polyethylene PE made better quality, you should and The nearest aluminum-plastic plate manufacturers contact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA3xxx Mill-Finished Aluminum Strips Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords