AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

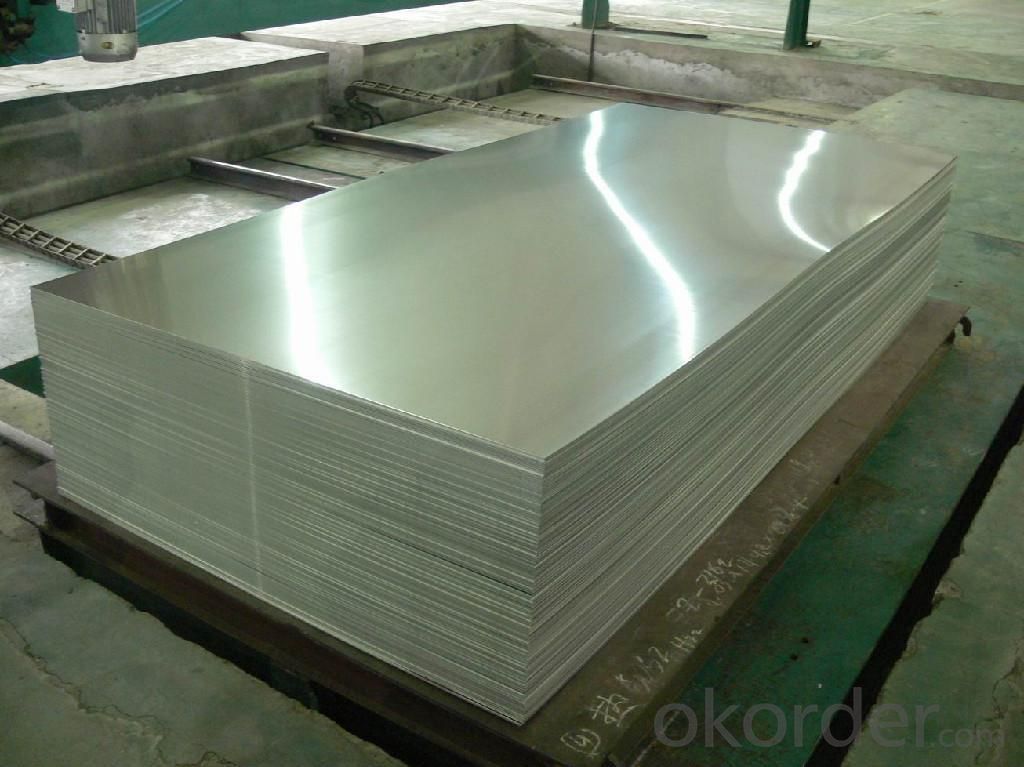

3.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Images

4.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Specification

Alloy | AA1xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q:Introduction of 6061 aluminium bar

- If a certain amount of manganese and chromium, can neutralize the bad effect of iron; sometimes add a small amount of copper or zinc, to improve the strength of the alloy, and the corrosion resistance decreased significantly;

- Q:I have an aluminum bar with a diameter of 14MM and a dent at the end of the bar, 4 wide and X10.5 deep,

- A three - edge 4 - edge cutter or saw cutter, which is milled in place.

- Q:What is the deformation temperature of the aluminum rod mold?

- It depends on the requirements of your equipment (imported or domestic) and refining the main function of control, there is a guarantee to improve the quality of continuous casting measures, such as the need of EMBR EMS mold expert system, all your requirements are not the same, the price difference is certainly much worse, I suggest you can design consulting institute the relevant information related to go directly to.

- Q:1000T machine with 130 aluminum extrusion aluminum rod, a supporting rod section, how long?

- According to 500- II 000 tons extrusion machine like to land 0 inland extrusion ratio control three 0- in about 50 m / M profile cast rod or section sectional area / sectional area of cast aluminum rod rod diameter according to the calculation of extrusion cylinder like situation according to 000T press with 0- II according to three or four 500.. In aluminum rod profile

- Q:What is the cause of the center crack in the casting of aluminum bars?

- Causes:1., the casting structure design is unreasonable, there are sharp corners, wall thickness change is too wide2., sand (core) concessions bad3. local overheating of mold

- Q:How does an ordinary lathe do a tensile test? A round aluminum bar

- Now the computer system through the controller, the control servo motor rotation speed control system, the reduction system slowdown by precision after the screw drives the moving beams of rise and fall, complete the tensile, compression, bending, shear and other mechanical properties test, has the following characteristics:Peel, tear, tensile, compression, strength, elongation, elongation and elastic modulus of seven independent test procedures;

- Q:What can make the aluminum bar surface shiny?

- 2, the formation of aluminum hydroxide3, aluminum hydroxide heating decompositionCase 2: low concentration dilute hydrochloric acid solution (HCL)1. Dip the alumina into dilute hydrochloric acid of low concentration2, after a period of three, remove two aluminum oxide

- Q:Their own factories need to invest much money

- What's the market like?. I helped my relatives in the past few years, but I always have to hide from the EPA

- Q:What brand of easy cutting and deformation of aluminum bar?

- Aluminum Alloy with the grade increased, the hardness is gradually rising, can try the next 6 series such as 6061, the machining deformation with selection of cutting fluid, because the process will produce high temperature, Aluminum Alloy heating become soft, resulting in deformation and sticking to the knife and other issues, semi synthetic cutting fluid has good cooling, lubrication and cleaning effect of processing, the most suitable Aluminum Alloy,

- Q:I know that aluminum rod forming is roughly after melting, casting slag mixing, so several links, only for the specific details of the process (i.e. work instruction) is not very clear, I hope this familiar person can detailed, thank you!

- In fact, you are talking about a few stepsIt is important to filter out the impurities after the melt is finished. It determines the fine degree of the object after molding

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products