AA1xxx Mill-Finished Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA1xxx Mill-Finished Aluminum Sheets Used for Construction is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Mill-Finished Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

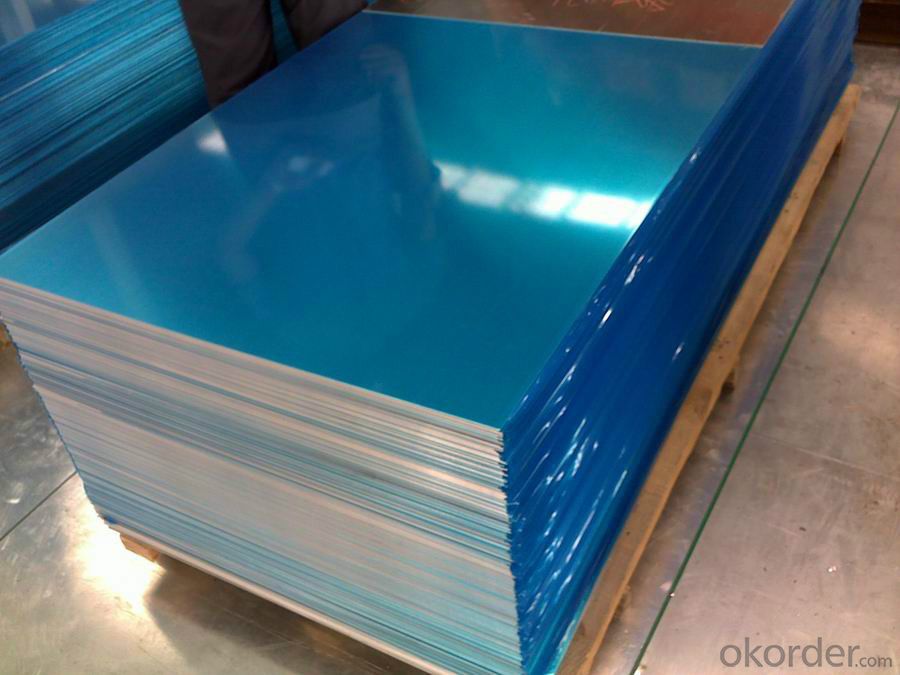

3.AA1xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA1xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060,AA1070, etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q:Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q:What are the different methods of punching aluminum sheets?

- Various techniques are employed to punch aluminum sheets, each possessing unique advantages and limitations. Presented below are some of the most commonly used methods: 1. Manual Punching: The most fundamental approach involves the use of handheld punch tools to manually create holes or shapes in aluminum sheets. It is suitable for small-scale projects and uncomplicated designs, yet it may be time-consuming and less accurate when compared to alternative methods. 2. Mechanical Punching: Mechanical punching machines utilize a mechanical press equipped with a punch and die set to puncture holes or form shapes in aluminum sheets. Such machines offer higher production rates, improved accuracy, and repeatability. This method is well-suited for medium to large-scale projects. 3. CNC Punching: Computer Numerical Control (CNC) punching machines employ computer programming to control the motion of the punch and die set. This technique enables the creation of intricate shapes, patterns, and multiple holes in a single operation. CNC punching provides exceptional precision, efficiency, and versatility, making it highly sought after in industrial settings. 4. Laser Punching: Laser punching merges laser cutting and punching technologies. A high-powered laser beam heats and softens the aluminum sheet, followed by a mechanical punch that forms the desired hole or shape. Laser punching delivers superior precision, speed, and the capability to work with various materials and thicknesses. It is commonly employed in the automotive and aerospace industries. 5. Waterjet Punching: Waterjet punching involves using a high-pressure stream of water mixed with abrasive substances to cut through aluminum sheets. This method is ideal for cutting intricate shapes and thick materials. It boasts exceptional precision, minimal material distortion, and the ability to work with a diverse range of materials. The choice of punching method depends on factors such as design complexity, required precision, production volume, and budgetary considerations. It is crucial to consider these factors and seek guidance from professionals to determine the most appropriate punching method for a specific application involving aluminum sheets.

- Q:i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- It depends on what properties you are interested in. If you want specific answers, you need to ask specific questions. The previous answerers are not very well informed... There are, in fact, many excellent Al based casting alloys. And... cast alloys of brass, pot metal, lead, etc are not very similar to Al (but, again, it depends on specifically what properties you want). Consult your friendly neighborhood metallurgist but think about exactly what characteristics you need to have. The more completely you can define your requirements, the better someone can advise you on the pros and cons of different material selections.

- Q:What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application it is being used for. Generally, aluminum sheets have a relatively high fatigue strength compared to other materials, allowing them to withstand a large number of cyclic loading cycles before failure. However, it is important to note that fatigue life can be influenced by various factors such as stress levels, loading conditions, and environmental factors like temperature and humidity. Aluminum sheets may experience a decrease in fatigue life when subjected to high stress levels, cyclic loading, or harsh environmental conditions. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an infinite fatigue life. On the other hand, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a finite fatigue life that can range from thousands to millions of cycles. To determine the precise fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more accurate information based on the specific parameters and conditions of use.

- Q:How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q:Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

- Q:im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q:What are the different types of patterns available for aluminum sheets?

- Aluminum sheets come in a wide range of patterns, each with its own unique visual and functional appeal. Here are some popular patterns that you can find: 1. Diamond Pattern: This pattern features raised diamonds created by intersecting parallel lines at 60-degree angles. It offers excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern mimics the texture of traditional stucco plaster, with a pebble-like surface. It provides enhanced durability and is often used decoratively on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern creates a rustic and artistic appearance with its dimpled texture. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets have small holes that offer great ventilation and visibility. They are commonly used in architectural applications like facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern adds depth and visual interest with raised designs or patterns on the sheet's surface. It is ideal for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern creates a sleek and modern look by giving the aluminum sheet a uniform directional grain. It is often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern features parallel raised ridges or lines on the sheet's surface, offering improved strength and rigidity. It is suitable for applications that require structural support or reinforcement. These examples showcase the variety of patterns available for aluminum sheets. When selecting the right pattern for a specific application, it is essential to consider the specific requirements and desired aesthetic.

- Q:Can the aluminum sheets be used for solar panel frames?

- Indeed, solar panel frames can indeed be constructed using aluminum sheets. The lightweight and robust characteristics of aluminum render it a favored material for solar panel frames. Its resistance to corrosion acts as a safeguard against rain, humidity, and UV rays, thereby shielding the frames from environmental elements. Furthermore, the recyclability of aluminum makes it an eco-friendly alternative for solar panel frames. Thanks to the adaptability and resilience of aluminum sheets, they are a fitting selection for supporting and safeguarding solar panels, guaranteeing their enduring functionality and efficiency.

- Q:Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems. Aluminum is commonly used in HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. The 101 aluminum alloy is a commonly used grade that provides good strength and ductility, making it suitable for HVAC applications. It is often used for fabricating ducts, air handlers, heat exchangers, and other components in HVAC systems. Additionally, aluminum sheets are easy to work with and can be easily formed and shaped according to the specific requirements of the HVAC system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1xxx Mill-Finished Aluminum Sheets Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords