AA1100 3003 Aluminum Embossed Sheet Stucco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

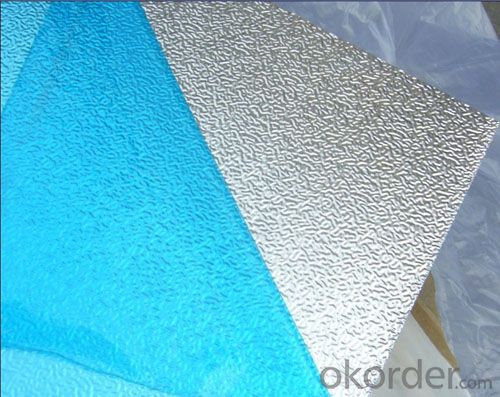

1. Description of AA1100 3003 Aluminum Embossed Sheet Stucco

The embossed oxidized panel is beautiful, with thickness from 0.25mm to 2.0mm, while the maximum width is 1250mm, after pattern embossed, the thickness could be 0.25 to 2.0mm. Additionally, we offer processing service for anodizing aluminum sheet, which could further strength sheet’s ability of anti-corrosion.

Pattern: Rhombic veins, orange peel veins, diamond veins, five-rib veins etc.

2. Specifications of AA1100 3003 Aluminum Embossed Sheet Stucco

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’special requirements | ||||||

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

4. Image of AA1100 3003 Aluminum Embossed Sheet Stucco

5. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q:Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q:How do you prevent scratches during transportation of aluminum sheets?

- To prevent scratches during transportation of aluminum sheets, it is important to use protective measures such as wrapping the sheets in a cushioning material like foam or bubble wrap. Additionally, using appropriate packaging techniques such as stacking the sheets securely and avoiding any direct contact with sharp or abrasive objects can help minimize the risk of scratches.

- Q:Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q:What kind of paint should be sprayed on the aluminium board?

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q:What is the use?

- The three and 3000 series aluminum on behalf of 300330033A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 written columns, is a commonly used alloy series.The four and 4000 series aluminum aluminum on behalf of 4A014000 series belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceThe five and 5000 Series 5052.5005.5083.5A05 series.5000 series aluminum plate belongs to the representative of the more commonly used aluminium alloy series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing. Oxidation belongs to one of the more mature aluminum series in China 5000 series aluminum plate.

- Q:why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q:could magnet attract iron with the seperation of rubber and aluminum sheets?

- It does in theory, but rubber and aluminum sheets can’t be too thick, larger magnetic force of magnet will be better.

- Q:Can 101 aluminum sheets be bent or formed into different shapes?

- Yes, 101 aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable material, which means it can be easily shaped without breaking or cracking. The specific grade of aluminum, in this case, 101, refers to the alloy composition and may have certain properties that make it more suitable for bending and forming. However, the ability to bend or form aluminum sheets also depends on their thickness, as thicker sheets may require more force and specialized equipment. Overall, with the right tools and techniques, it is possible to bend or form 101 aluminum sheets into a variety of shapes to meet specific requirements.

- Q:Can aluminum sheet be used for solar panels?

- Yes, aluminum sheet can be used for solar panels. Aluminum is a commonly used material in the construction of solar panels due to its combination of strength, durability, and lightweight properties. It is often used as the frame or mounting structure for the panels, providing support and stability. Additionally, aluminum is highly resistant to corrosion, which is important for solar panels that are exposed to the elements. Furthermore, aluminum is a highly conductive material, allowing for efficient transfer of electricity generated by the solar cells within the panel. Overall, using aluminum sheet in the construction of solar panels helps enhance their performance, longevity, and overall efficiency.

- Q:How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets are widely recognized for their remarkable flexural strength properties. Their inherent structural integrity and high strength-to-weight ratio allow them to endure bending forces without experiencing significant deformation or failure. The flexural strength of aluminum sheets is subject to variation based on factors like the chosen alloy, temper, and sheet thickness. Nevertheless, aluminum sheets are generally acknowledged for their impressive resistance to bending and ability to withstand applied loads without buckling or breaking. Consequently, aluminum sheets find extensive application in industries such as construction, automotive, aerospace, and marine, where components must endure flexural stresses. Furthermore, the flexural strength of aluminum sheets can be further enhanced through the utilization of diverse fabrication techniques and alloying elements, thereby optimizing their suitability for specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1100 3003 Aluminum Embossed Sheet Stucco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords