AA1070 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1060 Prepainted Aluminium Coils Used for Construction Description

AA1060 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1060 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1060 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

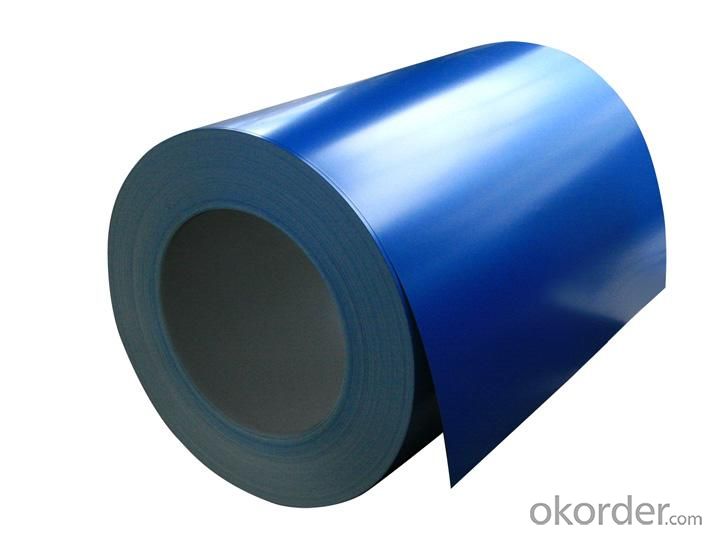

3.AA1060 Prepainted Aluminium Coils Used for Construction Images

4.AA1060 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1060 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Aluminum extrusions are bars made with hollow cavities that allow each to be joined easily, using special connectors. The primary difficulty when painting aluminum extrusions centers on the fact that they are nonporous and durable. Each of these traits creates a complication of its own.

- Your question supposes that you need to Paint the Aluminum Extrusion. The more common thing to do is to Anodize the extrusion. This process coats all surfaces with a hard durable coating. There are several colors available. Actually It's common to use Urethane's to paint Aluminum and the primer isn't simply made for metal, but is specifically for Aluminum. A lot of Airplanes are coated every day in this manner. Methods for coating the insides of tubing have been used for a very long time. You basically fill the tube with primer or coating then drain the excess out (dip method) and difficult shapes can be powder coated or electro static coated. Extrusions can be roller coated after cleaning, vinyls work very well with out priming. Think Toothpaste tubes.

- Q:I know aluminum has 3 valence electrons and oxygen has 7, but if anyone could explain the chemical formula to me it would be great.

- You are right about aluminum having 3 valence electrons, but oxygen has 6. Oxygen wants two more to get to 8. So the ions are Al +3 and O-2. The formula is Al2O3

- Q:Can aluminum coils be used in wastewater treatment plants?

- Indeed, wastewater treatment plants can utilize aluminum coils. These coils are frequently employed in the fabrication of heat exchangers, which play a crucial role in wastewater treatment plants. Heat exchangers function by transferring heat from the wastewater to the treatment procedure, thereby enhancing treatment efficiency and minimizing energy usage. Aluminum coils are favored in certain situations due to their exceptional thermal conductivity, lightweight nature, and resistance to corrosion. These characteristics render them suitable for the demanding conditions found in wastewater treatment plants. Furthermore, aluminum coils are cost-efficient and possess a prolonged lifespan, thus establishing them as a dependable option for implementation in wastewater treatment facilities.

- Q:Aluminum reacts with water so why is it used in buildings and cooking??Some help by today would be good!! :DThanxx

- Aluminum reacts with water under certain conditions, but cookware does not usually present any of those conditions. Aluminum cookware takes advantage of the oxidizing process, which creates a natural protective layer over the aluminum. It doesn't react with water in the same way that chemical equations say it will because cooking surfaces are designed to maximize the oxidation effect. This is basically the same reason why aluminum foil doesn't react in water. In building materials, it's less about exposure to the elements and more about how cheap and lightweight it is. Many building materials are aluminum alloys, which makes them more susceptible to corrosion than purer aluminum, and the use of aluminium roofing material, though fairly corrosion-resistant by itself (for the same reasons as cookware), gets compromised by the proximity of other metals used in construction, like non-stainless steel nails and screws, for example, or copper pipes without insulation. The trade-off is that aluminium alloys hold their shape better and have greater tensile strength, some of which approach that of steel.

- Q:Can aluminum coils be used for window frames?

- Yes, aluminum coils can be used for window frames. Aluminum is a popular choice for window frames due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial applications. Aluminum coils can be easily shaped and manipulated to fit various window sizes and styles. Furthermore, aluminum frames offer excellent thermal insulation properties, which can help improve energy efficiency in buildings. Overall, aluminum coils are a reliable and practical option for window frame construction.

- Q:Are aluminum coils suitable for electrical insulation applications?

- No, aluminum coils are not suitable for electrical insulation applications. Aluminum is a highly conductive material, meaning it allows the flow of electricity. In electrical applications, insulation is required to prevent the flow of electricity and protect against short circuits or electrical shocks. Therefore, materials with low electrical conductivity, such as plastics, rubber, or fiberglass, are commonly used for electrical insulation purposes.

- Q:What are the fire resistance properties of aluminum coils?

- Aluminum coils have excellent fire resistance properties due to the inherent characteristics of aluminum, such as its high melting point and low flammability. Aluminum does not burn, but instead forms a protective oxide layer on its surface when exposed to heat or flames. This oxide layer serves as a barrier, preventing further oxidation and combustion. Additionally, aluminum has a high thermal conductivity, which helps to dissipate heat quickly, further reducing the risk of fire. Overall, aluminum coils are considered to be highly resistant to fire.

- Q:Are aluminum coils suitable for pharmaceutical vial caps?

- Yes, aluminum coils are suitable for pharmaceutical vial caps. Aluminum is a commonly used material in the pharmaceutical industry due to its excellent barrier properties, corrosion resistance, and ability to be easily sterilized. It provides a tight seal, ensuring the integrity and safety of the vial contents. Additionally, aluminum coils can be easily formed into the desired shape and size for vial caps, making them a reliable choice for pharmaceutical packaging.

- Q:Are aluminum coils resistant to fire?

- Aluminum coils are widely recognized as being fire-resistant. They possess a high melting point of 660 degrees Celsius, which is considerably higher than the typical temperature of most household fires. Consequently, aluminum coils are a favored choice for diverse applications requiring fire resistance, including the construction of buildings, electrical systems, and automotive components. Moreover, aluminum exhibits low flammability and does not emit toxic fumes when exposed to fire, further heightening its fire-resistant characteristics. Nonetheless, it is vital to acknowledge that the fire resistance of aluminum coils may vary depending on the specific alloy employed and the thickness of the coil. Hence, it is always advisable to seek advice from experts or adhere to industry standards to guarantee the implementation of appropriate fire safety precautions.

- Q:I read the back of my deodorant and it said that it contains 14% Aluminum. Is that harmful for my baby?

- It's probably an anti-perspirant, right? That blocks sweat glands and is not healthy for you; not sure about the baby. You should only use deodorant - not anti-perspirant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1070 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords