AA1070 C.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1070 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

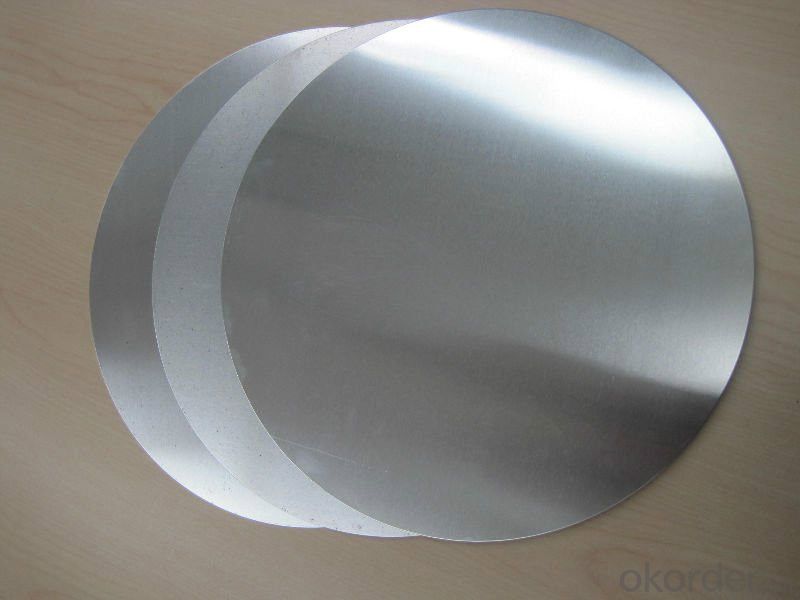

3.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q:How to refine the crystallization of cast aluminium bars

- First, add refiners such as aluminum, titanium, boron, silk, and second to increase cooling rates, such as water cooling.

- Q:What's the hardness of 7075 aluminum bars?

- Tensile strength 524Mpa:0.2%Yield strength 455Mpa: elongation 11%Modulus of elasticity E/Gpa:71Hardness: 150HBDensity: 2850

- Q:When an aluminum bar and an iron bar are inserted into the water to conduct electricity, are there any floating objects? Why?

- 6. aluminum with a hammer, prone to depression, iron is not easy 7. wire insulation sheath around the circle, much as possible (such as 100), multimeter to measure resistance, the slow response of the pointer is iron reaction of aluminum is fast.

- Q:Is it 76012000, 76042900 or 7604291010? Thank you very much! Urgently!! FiveIs it 76012000, 76042900 or 7604291010? Thank you According to our engineers might be unwrought Aluminum Alloy, but from the cylindrical shape should be cylindrical solid Aluminum Alloy, the two different export tariffs, were 0 and 15, we export alloy ingots are written Aluminum Alloy unwrought aluminum bar, whether can also write this? In fact, these two processes are the same. Thank you for your advice, thank you! Urgently!!!

- Only at 76012000 and 7604291010, which should be forged;Personally think it should be the first 76012000

- Q:How to break the tooth of woodworking saw blade for cutting aluminum rod

- Aluminum alloy saw blade used for cutting aluminumYou cut the aluminum with a woodworking saw blade, and their teeth will damage you in a different wayFor cutting aluminum, buy professional saw blades

- Q:What can make the aluminum bar surface shiny?

- Aluminum is more complex. Aluminum itself is soft. Hand polishing is difficult to reach the mirror surface. Generally, the grinding force of the machine at high speed is used to reach the mirror surface

- Q:How to control the casting speed of casting 90 aluminium bars

- If the water temperature is greater than 40, the water temperature must be reduced in other ways.Looking for national casting orders, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order network

- Q:The difference between aluminium bars 6061a and 6061

- If the use of pure aluminum packaging is still able to maintain the effect.

- Q:What are the elements of the national standard aluminum rod 6063t5?

- 6063 aluminum rod is a low alloying Al-Mg-Si system high plasticity alloyHas many valuable characteristics:Heat treatment strengthening, high impact toughness, is not sensitive to defectsHave excellent thermoplastic, can be squeezed into a high-speed complex structure. The hollow thin wall. Various profiles or forged into the complex structure of the forging, quenching temperature range, the quenching sensitivity is low, extrusion and forging after stripping, as long as the temperature is higher than the quenching temperature.

- Q:Now there's a company that makes aluminum alloy ingots and aluminum bars. I wonder if it's ok

- Price volatility is not very good to master, but the market outlook is goodAskIs this market big? Is there only a large amount of auto parts factory? Which industries use this aluminum alloy ingot and aluminum bar? 1 tons deduct a percentage from 50 yuan, OK?Chasing the answerAluminum ingot, aluminum ingot in the profile industry also used ah, aluminum ingot Market should be better

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1070 C.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products